Introduction

When designing embedded systems and connecting multiple devices, choosing the right communication protocol is crucial for efficient data transfer and system performance. Two widely used protocols in the embedded world are I2C (Inter-Integrated Circuit) and SPI (Serial Peripheral Interface). While both protocols enable communication between integrated circuits, they have distinct characteristics, advantages, and limitations. In this article, we will explore the key differences between I2C and SPI, helping you make informed decisions when selecting a protocol for your projects.

What is I2C?

Overview of I2C Protocol

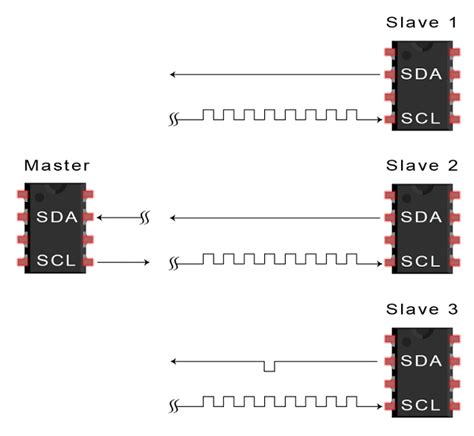

I2C, short for Inter-Integrated Circuit, is a synchronous serial communication protocol developed by Philips Semiconductors (now NXP Semiconductors) in the 1980s. It is designed to provide a simple, efficient, and standardized method for connecting multiple devices on a single bus. I2C uses a master-slave architecture, where one or more master devices initiate and control the communication with slave devices.

I2C Communication Lines

I2C communication requires only two bidirectional open-drain lines:

- SDA (Serial Data): This line is used for transmitting and receiving data between the master and slave devices.

- SCL (Serial Clock): This line carries the clock signal generated by the master to synchronize the data transfer.

Both lines are pulled up to the supply voltage using pull-up resistors, which ensure a default high state when no device is actively driving the lines low.

I2C Addressing

Each slave device connected to the I2C bus has a unique 7-bit or 10-bit address. The master initiates communication by sending a START condition followed by the slave device address. If a slave device recognizes its address, it responds with an ACK (acknowledge) signal, indicating its readiness for communication. The master then proceeds to send or request data from the slave device.

I2C Data Transfer

Data transfer on the I2C bus is byte-oriented. After the addressing phase, the master sends or receives data one byte at a time. Each byte is followed by an ACK or NACK (not acknowledge) signal from the receiver to indicate whether the byte was successfully received or if an error occurred. The master generates a STOP condition to terminate the communication.

I2C Speed Modes

I2C supports different speed modes to accommodate various system requirements:

- Standard mode: Up to 100 kbit/s

- Fast mode: Up to 400 kbit/s

- Fast mode plus: Up to 1 Mbit/s

- High-speed mode: Up to 3.4 Mbit/s

- Ultra-fast mode: Up to 5 Mbit/s

Higher speed modes may require specific hardware considerations, such as stronger pull-up resistors and shorter bus lengths.

What is SPI?

Overview of SPI Protocol

SPI, which stands for Serial Peripheral Interface, is a synchronous serial communication protocol developed by Motorola (now NXP Semiconductors). It provides full-duplex communication between a master device and one or more slave devices. SPI is known for its simplicity, high speed, and flexibility in connecting multiple devices.

SPI Communication Lines

SPI communication typically involves four lines:

- MOSI (Master Out Slave In): This line carries data from the master to the slave devices.

- MISO (Master In Slave Out): This line carries data from the slave devices to the master.

- SCLK (Serial Clock): This line carries the clock signal generated by the master to synchronize the data transfer.

- SS/CS (Slave Select/Chip Select): This line is used by the master to select the slave device for communication. Each slave device has its own SS/CS line.

SPI Slave Selection

In SPI, the master device selects the slave device it wants to communicate with by asserting the corresponding SS/CS line low. This allows the master to communicate with multiple slave devices on the same bus by individually selecting each slave using separate SS/CS lines.

SPI Data Transfer

SPI data transfer is full-duplex, meaning that data can be transmitted and received simultaneously. The master generates the clock signal and initiates the communication. Data is typically transferred in multiples of 8 bits, with the most significant bit (MSB) being transmitted first. The master and slave devices shift out data on the MOSI and MISO lines, respectively, on each clock cycle.

SPI Modes and Clock Polarity

SPI supports four different modes that determine the clock polarity (CPOL) and clock phase (CPHA). These modes define the idle state of the clock signal and the timing of data capture:

- Mode 0 (CPOL = 0, CPHA = 0): Clock idle state is low, data is captured on the rising edge.

- Mode 1 (CPOL = 0, CPHA = 1): Clock idle state is low, data is captured on the falling edge.

- Mode 2 (CPOL = 1, CPHA = 0): Clock idle state is high, data is captured on the falling edge.

- Mode 3 (CPOL = 1, CPHA = 1): Clock idle state is high, data is captured on the rising edge.

The specific mode used depends on the requirements of the communicating devices and must be agreed upon by both the master and slave devices.

Key Differences Between I2C and SPI

Pin Count and Wiring

| Protocol | Data Lines | Clock Line | Slave Select | Total Lines |

|---|---|---|---|---|

| I2C | 1 (SDA) | 1 (SCL) | N/A | 2 |

| SPI | 2 (MOSI, MISO) | 1 (SCLK) | 1 per slave (SS/CS) | 3 + number of slaves |

I2C requires fewer pins compared to SPI. I2C uses only two lines (SDA and SCL) for communication, regardless of the number of slave devices. In contrast, SPI requires three lines (MOSI, MISO, SCLK) plus an additional SS/CS line for each slave device. This can lead to increased pin count and wiring complexity in SPI systems with multiple slave devices.

Communication Speed

| Protocol | Speed Range |

|---|---|

| I2C | Up to 5 Mbit/s (ultra-fast mode) |

| SPI | Typically up to tens of Mbit/s |

SPI generally offers higher communication speeds compared to I2C. While I2C has various speed modes, with the ultra-fast mode reaching up to 5 Mbit/s, SPI can easily achieve speeds in the range of tens of Mbit/s. The actual speed in SPI is limited by factors such as the maximum clock frequency supported by the devices and the bus capacitance.

Addressing and Device Selection

I2C uses a unique addressing scheme to identify slave devices on the bus. Each slave device has a predefined address, and the master communicates with a specific slave by including its address in the communication. This allows multiple slave devices to share the same bus without additional hardware for device selection.

SPI, on the other hand, does not have a built-in addressing mechanism. Instead, it uses separate SS/CS lines to select the desired slave device for communication. The master asserts the corresponding SS/CS line low to enable communication with a specific slave device.

Data Transfer

| Protocol | Data Transfer Type | Data Transfer Size |

|---|---|---|

| I2C | Byte-oriented | 8 bits at a time |

| SPI | Full-duplex | Configurable (typically 8 bits or more) |

I2C follows a byte-oriented data transfer approach. Data is transmitted and received one byte at a time, with each byte followed by an acknowledgment bit. This makes I2C suitable for transferring small amounts of data or configuring registers on slave devices.

SPI supports full-duplex communication, allowing simultaneous transmission and reception of data. The data transfer size in SPI is configurable and typically ranges from 8 bits to 16 bits or more, depending on the requirements of the communicating devices. This makes SPI efficient for transferring larger amounts of data.

Arbitration and Collision Handling

I2C has built-in arbitration and collision detection mechanisms. If multiple master devices attempt to access the bus simultaneously, the arbitration process ensures that only one master gains control of the bus. Collisions are detected and resolved automatically, with the master devices backing off and retrying the communication.

SPI does not have inherent arbitration or collision detection. It relies on the master device to control the communication and avoid conflicts. In multi-master SPI systems, additional software or hardware mechanisms may be required to handle arbitration and prevent collisions.

Scalability and Flexibility

I2C is highly scalable and allows for easy addition of new devices to the bus. As long as each device has a unique address, it can be connected to the same I2C bus without modifying the existing hardware. This makes I2C suitable for systems with a varying number of devices.

SPI provides more flexibility in terms of data transfer size and clock speed. However, adding new devices to an SPI bus requires additional SS/CS lines and may involve hardware modifications. SPI is more suitable for systems with a fixed number of devices or when high-speed communication is a priority.

Advantages and Limitations

Advantages of I2C

- Fewer pins required, reducing wiring complexity and board space.

- Built-in addressing mechanism for easy device identification.

- Scalability and flexibility in adding new devices to the bus.

- Automatic arbitration and collision detection.

- Wide support and standardization across different manufacturers.

Limitations of I2C

- Lower maximum data transfer speed compared to SPI.

- Limited bus capacitance and pull-up resistor considerations for higher speeds.

- Byte-oriented data transfer, which may be less efficient for larger data transfers.

- Possible performance impact in multi-master systems due to arbitration overhead.

Advantages of SPI

- Higher data transfer speeds compared to I2C.

- Full-duplex communication for simultaneous data transmission and reception.

- Configurable data transfer size for efficient handling of larger data packets.

- Simplicity in hardware implementation and protocol.

- Lower power consumption due to the absence of pull-up resistors.

Limitations of SPI

- Increased pin count and wiring complexity, especially with multiple slave devices.

- No built-in addressing or device selection mechanism.

- Limited scalability due to the need for additional SS/CS lines for each slave device.

- Lack of standardization, requiring careful compatibility checks between devices.

- Potential for bus contention and collisions in multi-master systems without proper arbitration.

Choosing Between I2C and SPI

When deciding between I2C and SPI for your project, consider the following factors:

-

Pin count and wiring complexity: If minimizing pin count and simplifying wiring are important, I2C may be a better choice due to its two-wire interface. SPI requires more pins, especially when connecting multiple slave devices.

-

Communication speed: If high-speed data transfer is a critical requirement, SPI is generally the preferred choice. It offers faster data rates compared to I2C, making it suitable for applications that involve large amounts of data or real-time communication.

-

Device compatibility: Check the compatibility of the devices you plan to use in your project. Some devices may only support one protocol or have specific requirements. Ensure that all the devices in your system are compatible with the chosen protocol.

-

Scalability and flexibility: Consider the scalability and flexibility needs of your project. I2C allows for easy addition of new devices to the bus without hardware modifications, making it suitable for systems with varying device configurations. SPI provides more flexibility in terms of data transfer size and clock speed but may require hardware changes when adding new devices.

-

Software complexity: Evaluate the software complexity involved in implementing the chosen protocol. I2C has a well-defined standard and wide support across different platforms, which can simplify software development. SPI may require more low-level control and careful timing considerations.

-

Power consumption: If power consumption is a critical factor, SPI may have an advantage due to the absence of pull-up resistors. I2C requires pull-up resistors on the bus lines, which can contribute to higher power consumption, especially in systems with many devices.

-

Noise immunity: Consider the noise immunity requirements of your system. I2C’s open-drain architecture and lower data rates may provide better noise immunity compared to SPI’s higher speeds and push-pull signaling.

Ultimately, the choice between I2C and SPI depends on the specific requirements and constraints of your project. Careful evaluation of the above factors will help you make an informed decision and select the protocol that best suits your needs.

Frequently Asked Questions (FAQ)

1. Can I use both I2C and SPI in the same project?

Yes, it is possible to use both I2C and SPI in the same project. Many microcontrollers and embedded systems support multiple communication protocols, allowing you to choose the appropriate protocol for each device or subsystem based on their specific requirements.

2. Is it possible to connect I2C and SPI devices together?

No, I2C and SPI devices cannot be directly connected together. They have different signaling schemes, pin configurations, and communication protocols. To communicate between an I2C device and an SPI device, you would need to use a bridge or a microcontroller that supports both protocols and can act as an intermediary.

3. What is the maximum number of devices that can be connected to an I2C or SPI bus?

For I2C, the maximum number of devices that can be connected to the bus is determined by the available address space. With 7-bit addressing, up to 128 devices can be theoretically connected. However, practical limitations such as bus capacitance and pull-up resistor strength may restrict the actual number of devices.

In SPI, the maximum number of devices is limited by the number of available SS/CS lines on the master device. Each slave device requires a dedicated SS/CS line. The practical limit depends on the number of GPIO pins available on the master device.

4. Can I change the I2C or SPI clock speed dynamically?

Yes, it is possible to change the clock speed dynamically for both I2C and SPI. The clock speed can be adjusted by configuring the appropriate registers or settings in the master device. However, it’s important to ensure that all the devices on the bus support the desired clock speed and that the bus integrity is maintained.

5. Are there any variations or extensions of the I2C and SPI protocols?

Yes, there are several variations and extensions of the I2C and SPI protocols. For example, I2C has variations like SMBus (System Management Bus) and PMBus (Power Management Bus) that define additional features and requirements for specific applications.

SPI also has variations such as Quad SPI (QSPI) and Dual SPI (DSPI) that use additional data lines to increase the data transfer rate. These variations build upon the basic principles of SPI but offer enhanced functionality or performance.

Conclusion

Understanding the differences between I2C and SPI is crucial when designing embedded systems and selecting the appropriate communication protocol. I2C offers simplicity, fewer pins, and built-in addressing, making it suitable for systems with multiple devices and reduced wiring complexity. On the other hand, SPI provides higher data transfer speeds, full-duplex communication, and flexibility in data transfer size, making it ideal for applications that require high-speed data exchange.

When choosing between I2C and SPI, consider factors such as pin count, communication speed, device compatibility, scalability, software complexity, power consumption, and noise immunity. Evaluate the specific requirements and constraints of your project to make an informed decision.

By understanding the strengths and limitations of each protocol, you can select the most suitable communication interface for your embedded system, ensuring efficient data transfer, reliable operation, and optimal performance.

No responses yet