What is a PCB Etcher?

A PCB etcher, also known as a printed circuit board etching machine, is a device used to remove unwanted copper from a printed circuit board (PCB) during the manufacturing process. The purpose of etching is to create the desired electrical connections on the board by removing the copper that is not part of the circuit design.

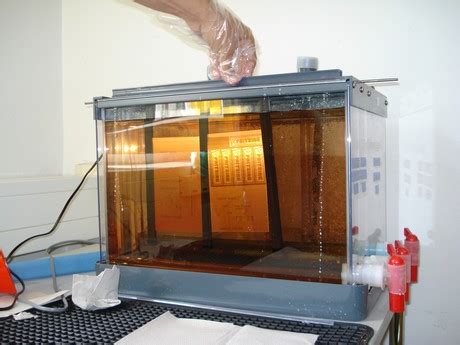

PCB Etching machines come in various sizes and configurations, ranging from small desktop units suitable for hobbyists and small-scale production to large industrial machines capable of handling high-volume manufacturing. The etching process typically involves exposing the PCB to a chemical solution that dissolves the unwanted copper while leaving the desired circuit pattern intact.

Types of PCB Etching Machines

There are several types of PCB etching machines available, each with its own advantages and disadvantages. Some of the most common types include:

-

Spray Etching Machines: These machines use a spray nozzle to apply the etching solution to the PCB surface. They offer good control over the etching process and can handle both single-sided and double-sided boards.

-

Bubble Etching Machines: In these machines, the PCB is submerged in an etching solution, and air bubbles are introduced to agitate the liquid and promote uniform etching. Bubble etching machines are simple and cost-effective but may not provide as much control as spray etching machines.

-

Conveyor Etching Machines: These automated machines use a conveyor belt to transport the PCBs through the etching solution. They are suitable for high-volume production and offer consistent results, but they are more expensive than other types of etching machines.

Advantages of Using a PCB Etching Machine

Using a PCB etching machine offers several benefits over manual etching methods:

-

Consistency: PCB etching machines provide consistent results, ensuring that each board is etched to the same specifications. This is particularly important in high-volume production, where inconsistencies can lead to costly errors.

-

Speed: Etching machines can process PCBs much faster than manual methods, significantly reducing production time and increasing output.

-

Precision: With precise control over the etching process, PCB etching machines can produce fine details and intricate circuit patterns that may be difficult to achieve with manual etching.

-

Safety: Automated etching machines minimize the need for human intervention, reducing the risk of exposure to hazardous chemicals used in the etching process.

How to Make a PCB Etching Machine

Building a PCB etching machine can be a rewarding project for electronics enthusiasts and hobbyists. While there are many different designs and configurations possible, the following steps outline a basic approach to creating a simple spray etching machine.

Materials Needed

- Plastic container with a lid (large enough to accommodate your PCBs)

- Aquarium air pump

- Aquarium air stone

- Plastic tubing

- Spray nozzle

- Heating element (aquarium heater or immersion heater)

- Temperature control switch

- DC power supply (12V)

- Peristaltic pump

- Etching solution (e.g., ferric chloride or ammonium persulfate)

Steps to Build the PCB Etching Machine

-

Prepare the Container: Drill holes in the lid of the plastic container for the spray nozzle, air stone, and heating element. Ensure the holes are properly sealed to prevent leaks.

-

Install the Spray Nozzle: Attach the spray nozzle to the container lid and connect it to the peristaltic pump using plastic tubing.

-

Set Up the Air Pump: Connect the aquarium air stone to the air pump using plastic tubing and place the air stone inside the container. The air stone will help agitate the etching solution and promote uniform etching.

-

Install the Heating Element: Place the heating element inside the container and connect it to the temperature control switch. The heating element will maintain the etching solution at the optimal temperature for efficient etching.

-

Connect the Power Supply: Connect the DC power supply to the peristaltic pump and temperature control switch.

-

Test and Calibrate: Fill the container with water and test the machine to ensure all components are working properly. Calibrate the temperature control switch to maintain the desired temperature for the etching solution.

-

Prepare the Etching Solution: Follow the manufacturer’s instructions to prepare the etching solution and pour it into the container.

Using Your PCB Etching Machine

Once your PCB etching machine is assembled and calibrated, you can use it to etch your circuit boards. The general process involves the following steps:

-

Design and Print Your PCB: Create your PCB design using CAD software and print the design onto a transparent film or use a photoresist-coated PCB.

-

Expose the PCB: If using a photoresist-coated PCB, expose the board to UV light through the transparent film to transfer the circuit pattern onto the board.

-

Develop the PCB: Immerse the exposed PCB in a developing solution to remove the unexposed photoresist, revealing the copper layer beneath.

-

Etch the PCB: Place the developed PCB into the etching machine and start the etching process. The machine will spray the etching solution onto the board, dissolving the unwanted copper.

-

Clean and Inspect: Once etching is complete, remove the PCB from the machine and rinse it with water. Inspect the board to ensure all unwanted copper has been removed and the desired circuit pattern is intact.

-

Drill and Finish: Drill any necessary holes for components and apply a protective finish, such as solder mask or silkscreen, if desired.

FAQ

-

What is the best etching solution to use in a PCB etching machine?

The two most common etching solutions are ferric chloride and ammonium persulfate. Ferric chloride is more widely used due to its availability and lower cost, but ammonium persulfate is less toxic and provides a cleaner finish. -

How long does it take to etch a PCB using an etching machine?

The etching time depends on factors such as the strength of the etching solution, the temperature, and the complexity of the circuit pattern. On average, etching a single-sided PCB takes between 5 to 15 minutes. -

Can I use a PCB etching machine to etch double-sided boards?

Yes, most PCB etching machines can handle double-sided boards. However, you may need to etch each side separately or use a machine specifically designed for double-sided etching. -

How often should I replace the etching solution in my machine?

The etching solution will become less effective over time as it dissolves copper from the PCBs. It’s generally recommended to replace the solution when etching times start to increase significantly or when the solution becomes saturated with copper. -

Are there any safety precautions I should take when using a PCB etching machine?

Yes, always wear protective gloves, goggles, and clothing when handling etching solutions, as they can be corrosive and toxic. Work in a well-ventilated area and dispose of used etching solutions properly, following local regulations.

| Component | Purpose |

|---|---|

| Plastic container | Holds the etching solution and PCB during the etching process |

| Aquarium air pump | Provides air to agitate the etching solution for uniform etching |

| Aquarium air stone | Disperses air bubbles evenly throughout the etching solution |

| Plastic tubing | Connects components such as the air pump, spray nozzle, and peristaltic pump |

| Spray nozzle | Applies the etching solution to the PCB surface |

| Heating element | Maintains the etching solution at the optimal temperature for efficient etching |

| Temperature control switch | Regulates the heating element to maintain the desired temperature |

| DC power supply | Powers the peristaltic pump and temperature control switch |

| Peristaltic pump | Pumps the etching solution from the container to the spray nozzle |

In conclusion, a PCB etching machine is an essential tool for anyone involved in the design and manufacturing of printed circuit boards. Whether you choose to purchase a commercial machine or build your own, an etching machine can greatly streamline the PCB production process, providing consistent results, increased precision, and faster turnaround times. By understanding the different types of etching machines available and the basic principles behind their operation, you can make an informed decision on the best solution for your PCB etching needs.

No responses yet