What is a Dpdt Relay?

A Double Pole Double Throw (DPDT) relay is an electrically controlled switch that has two inputs and four outputs. It allows you to switch two separate circuits using a single relay. The “double pole” refers to the fact that there are two separate switches that are controlled by the relay, and the “double throw” means that each of those switches can be connected to one of two outputs.

DPDT relays are used in a wide variety of applications where it is necessary to control two separate circuits with a single input signal. Some common examples include:

- Switching between two power sources

- Reversing the direction of a motor

- Switching between two sets of speakers

- Controlling two separate lighting circuits

How Does a DPDT Relay Work?

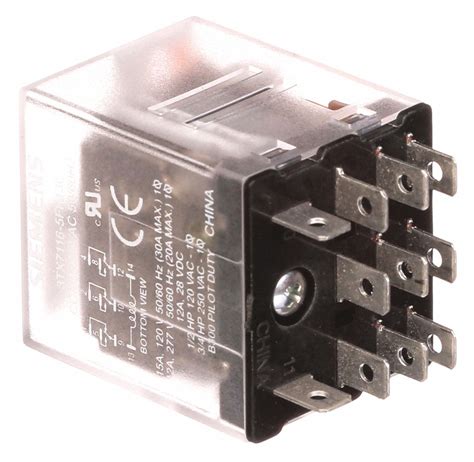

A DPDT relay consists of two separate sets of contacts, each of which includes a common terminal and two switched terminals. The common terminal is the input to the switch, and the switched terminals are the outputs. When the relay is not energized, the common terminal is connected to the normally closed (NC) switched terminal. When the relay is energized, the common terminal switches to the normally open (NO) switched terminal.

Here is a simple diagram showing the basic structure of a DPDT relay:

NC NO

_|_ _|_

COM1 --| \/ |--

| /\ |

-| | |-

| | |

_|_ _|_

NC NO

NC NO

_|_ _|_

COM2 --| \/ |--

| /\ |

-| | |-

| | |

_|_ _|_

NC NO

In this diagram, the two sets of contacts are labeled COM1 and COM2. When the relay is not energized, COM1 is connected to the NC terminal on the left, and COM2 is connected to the NC terminal on the right. When the relay is energized, COM1 switches to the NO terminal on the left, and COM2 switches to the NO terminal on the right.

The actual switching is done by an electromagnet inside the relay. When current flows through the coil of the electromagnet, it creates a magnetic field that attracts an armature. The armature is connected to the moving contacts of the switch, so when it moves, it changes the state of the switch.

DPDT Relay Specifications

When selecting a DPDT relay for a particular application, there are several key specifications to consider:

Coil Voltage

The coil voltage is the voltage required to energize the relay and switch the contacts. Common coil voltages include 5V, 12V, 24V, and 48V, although other voltages are available. It’s important to choose a relay with a coil voltage that is compatible with the control circuit that will be used to switch it.

Contact Rating

The contact rating specifies the maximum voltage and current that the relay contacts can handle. It’s important to choose a relay with contacts that are rated for the load that will be switched. If the load exceeds the contact rating, the contacts may wear out prematurely or even weld together.

Here is a table showing some common contact ratings for DPDT relays:

| Voltage | Current | Max Switching Power |

|---|---|---|

| 30V DC | 10A | 300W |

| 125V AC | 10A | 1250VA |

| 250V AC | 10A | 2500VA |

Switching Time

The switching time is the time required for the relay contacts to switch from one state to the other. Faster switching times are important in applications where the relay needs to respond quickly to changes in the control signal. Typical switching times for DPDT relays range from a few milliseconds to tens of milliseconds.

Mechanical Life

The mechanical life of a relay specifies the number of switching cycles that the relay can perform before the contacts wear out. Higher quality relays typically have longer mechanical life ratings. For example, a relay with a mechanical life of 10,000,000 cycles can be expected to last longer than one with a mechanical life of 100,000 cycles.

Connecting a DPDT Relay

Connecting a DPDT relay is relatively simple, but it’s important to follow the manufacturer’s wiring diagram to ensure proper operation. Here is a typical wiring diagram for a DPDT relay:

_____

| |

COM1 | | NC1

___| |___

| | | |

| | | |

| | | |

| |_____| |

| | | |

NO1 | | NO2

| |

COM2 |_____| NC2

In this diagram, the relay coil is not shown, but it would be connected to a separate control circuit that provides the necessary voltage to energize the relay.

To connect a load to the relay, simply connect one side of the load to the COM terminal and the other side to either the NC or NO terminal, depending on whether you want the load to be normally off or normally on. For example, if you want a light to be on when the relay is not energized, you would connect the light to the COM and NC terminals. If you want the light to be off when the relay is not energized, you would connect it to the COM and NO terminals.

DPDT Relay Applications

DPDT relays are used in a wide variety of applications across many different industries. Here are a few examples:

Automotive

In automotive applications, DPDT relays are often used to switch between two different power sources, such as a main battery and an auxiliary battery. They can also be used to control various accessories, such as lights, horns, and windshield wipers.

Industrial Control

In industrial control applications, DPDT relays are used to control various types of equipment, such as motors, solenoids, and valves. They can be used to switch between manual and automatic control modes, or to provide emergency stop functionality.

Home Automation

In home automation applications, DPDT relays can be used to control lighting, HVAC systems, and other household appliances. They can be controlled by a variety of inputs, such as sensors, timers, and remote controls.

Audio/Video

In audio/video applications, DPDT relays can be used to switch between different audio or video sources, such as multiple speakers or displays. They can also be used to mute or unmute audio signals.

DPDT Relay FAQs

Q: What is the difference between a DPDT relay and an SPDT Relay?

A: An SPDT (Single Pole Double Throw) relay has one input and two outputs, while a DPDT relay has two inputs and four outputs. In other words, an SPDT relay can switch a single circuit, while a DPDT relay can switch two separate circuits.

Q: Can a DPDT relay be used to control a motor?

A: Yes, a DPDT relay can be used to control a motor, but it’s important to choose a relay with contacts that are rated for the motor’s voltage and current. It’s also important to use a snubber circuit or other protection device to prevent damage to the relay contacts from the inductive kickback that occurs when the motor is switched off.

Q: How do I know what coil voltage to choose for my DPDT relay?

A: The coil voltage should match the voltage of the control circuit that will be used to switch the relay. For example, if the control circuit operates at 12V DC, you should choose a relay with a 12V DC coil.

Q: Can I use a DPDT relay to switch AC power?

A: Yes, DPDT relays can be used to switch AC power, but it’s important to choose a relay with contacts that are rated for the AC voltage and current that will be switched. AC rated relays typically have a higher contact rating than DC rated relays.

Q: How long can I expect a DPDT relay to last?

A: The lifespan of a DPDT relay depends on several factors, including the quality of the relay, the amount of use it gets, and the type of load it is switching. In general, a high-quality relay with a mechanical life rating of 10,000,000 cycles or more can be expected to last for many years in most applications. However, if the relay is used frequently or is switching a heavy load, it may wear out more quickly.

Conclusion

DPDT relays are a versatile and widely used component in many different applications. They provide a simple and effective way to switch two separate circuits using a single control signal, and they are available in a wide range of specifications to suit different needs.

When selecting a DPDT relay, it’s important to consider factors such as the coil voltage, contact rating, switching time, and mechanical life. It’s also important to follow the manufacturer’s wiring diagram and to use appropriate protection devices, such as snubber circuits, to ensure safe and reliable operation.

Whether you’re working on an automotive, industrial, home automation, or audio/video project, chances are good that a DPDT relay can help you achieve your goals. With a little knowledge and careful selection, you can incorporate these handy devices into your designs with confidence.

No responses yet