What is Battery Internal Resistance?

Battery internal resistance is a measure of the opposition to current flow within a battery cell. It is an important parameter that affects the performance and efficiency of a battery. The internal resistance of a battery is composed of several components, including:

- Electrolyte resistance: The resistance of the electrolyte solution to the flow of ions between the electrodes.

- Electrode resistance: The resistance of the electrodes themselves, which depends on their material properties and surface area.

- Separator resistance: The resistance of the separator material, which acts as a barrier between the electrodes while allowing the flow of ions.

- Contact resistance: The resistance at the interfaces between the electrodes, current collectors, and terminals.

The total internal resistance of a battery is the sum of these individual components. It is typically measured in milliohms (mΩ) or microohms (μΩ).

Factors Affecting Battery Internal Resistance

Several factors can influence the internal resistance of a battery, including:

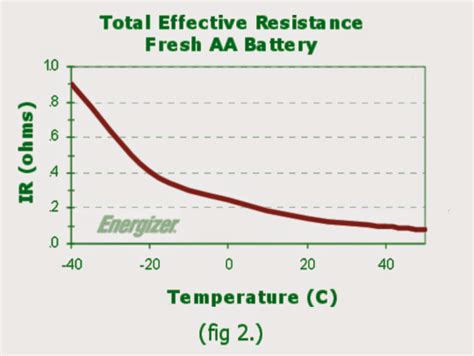

- Temperature: Higher temperatures generally reduce internal resistance, while lower temperatures increase it.

- State of Charge (SOC): The internal resistance of a battery varies with its state of charge. It is typically lowest when the battery is fully charged and increases as the battery discharges.

- Age and Cycle Life: As a battery ages and undergoes repeated charge-discharge cycles, its internal resistance tends to increase due to degradation of the electrodes and electrolyte.

- Current Draw: The internal resistance of a battery can be affected by the amount of current being drawn from it. Higher current draws can lead to increased internal resistance.

Why is Measuring Battery Internal Resistance Important?

Measuring the internal resistance of a battery is crucial for several reasons:

1. Battery Performance

The internal resistance of a battery directly impacts its performance. A higher internal resistance results in a greater voltage drop when current is drawn from the battery, leading to reduced output voltage and power. This can cause devices powered by the battery to perform poorly or fail to operate altogether.

2. Battery Efficiency

A battery with high internal resistance will dissipate more energy as heat during charging and discharging, reducing its overall efficiency. This wasted energy can lead to shorter runtime, longer charging times, and increased heat generation.

3. Battery Health Monitoring

Measuring the internal resistance of a battery over time can provide valuable insights into its health and remaining useful life. As a battery ages and deteriorates, its internal resistance typically increases. By monitoring this parameter, it is possible to detect when a battery is approaching the end of its life and needs to be replaced.

4. Safety

In extreme cases, high internal resistance can cause a battery to overheat or even catch fire. By regularly measuring internal resistance, potential safety issues can be identified and addressed before they become serious problems.

Methods for Measuring Battery Internal Resistance

There are several methods for measuring the internal resistance of a battery, each with its own advantages and limitations. Some of the most common methods include:

1. DC Load Test

The DC load test involves applying a known load to the battery and measuring the resulting voltage drop. The internal resistance can then be calculated using Ohm’s law:

R = ΔV / I

Where:

– R is the internal resistance in ohms (Ω)

– ΔV is the voltage drop in volts (V)

– I is the applied current in amperes (A)

To perform a DC load test:

- Measure the open-circuit voltage (OCV) of the battery using a voltmeter.

- Connect a known load (such as a resistor) across the battery terminals.

- Measure the voltage across the battery while the load is applied.

- Calculate the internal resistance using the formula above.

| Step | Description | Value |

|---|---|---|

| 1 | Open-circuit voltage (OCV) | 12.6V |

| 2 | Applied load resistance | 0.1Ω |

| 3 | Voltage under load | 12.2V |

| 4 | Internal resistance (R = (12.6V – 12.2V) / (12.2V / 0.1Ω)) | 33mΩ |

The DC load test is simple to perform but has some limitations. It requires disconnecting the battery from any connected devices and can be affected by the battery’s state of charge and temperature.

2. AC Impedance Spectroscopy

AC impedance spectroscopy involves applying a small AC signal to the battery and measuring its response across a range of frequencies. This method provides a more comprehensive characterization of the battery’s internal resistance, as it can separate the contributions of various components (electrolyte, electrodes, etc.) based on their frequency response.

To perform AC impedance spectroscopy:

- Connect the battery to an impedance analyzer or potentiostat equipped with frequency response analysis capabilities.

- Apply a small AC signal (typically 5-10mV) across a range of frequencies (often from 1mHz to 1MHz).

- Measure the battery’s response at each frequency and plot the results on a Nyquist plot or Bode plot.

- Analyze the plot to determine the battery’s internal resistance and other impedance parameters.

AC impedance spectroscopy provides detailed information about a battery’s internal resistance but requires specialized equipment and can be time-consuming to perform.

3. Pulse Load Test

The pulse load test involves applying a short current pulse to the battery and measuring the resulting voltage response. The internal resistance can be calculated from the instantaneous voltage drop and the applied current:

R = ΔV / ΔI

Where:

– R is the internal resistance in ohms (Ω)

– ΔV is the instantaneous voltage drop in volts (V)

– ΔI is the applied current pulse in amperes (A)

To perform a pulse load test:

- Measure the open-circuit voltage (OCV) of the battery using a voltmeter.

- Apply a short current pulse (typically 1-10ms) to the battery using a programmable load or electronic load.

- Measure the instantaneous voltage drop at the beginning of the current pulse.

- Calculate the internal resistance using the formula above.

| Step | Description | Value |

|---|---|---|

| 1 | Open-circuit voltage (OCV) | 12.6V |

| 2 | Applied current pulse | 10A |

| 3 | Instantaneous voltage drop | 0.3V |

| 4 | Internal resistance (R = 0.3V / 10A) | 30mΩ |

The pulse load test is relatively quick and can be performed without disconnecting the battery from its connected devices. However, it requires specialized equipment capable of generating and measuring short current pulses.

Interpreting Battery Internal Resistance Measurements

Once you have measured the internal resistance of a battery, it is important to interpret the results correctly. The acceptable range of internal resistance values depends on the battery chemistry, size, and intended application.

For example, a typical lead-acid car battery may have an internal resistance of 5-15mΩ when new, while a small lithium-ion cell for portable electronics may have an internal resistance of 100-300mΩ. It is essential to consult the manufacturer’s specifications or industry standards to determine the acceptable range for a particular battery type.

If the measured internal resistance is significantly higher than the expected value, it may indicate that the battery is degraded or damaged. High internal resistance can lead to reduced performance, longer charging times, and increased heat generation. In some cases, it may be necessary to replace the battery to ensure safe and reliable operation.

Frequently Asked Questions (FAQ)

1. Can I measure the internal resistance of a battery while it is connected to a device?

It depends on the measurement method used. The DC load test and AC impedance spectroscopy generally require the battery to be disconnected from any devices, while the pulse load test can be performed with the battery connected. However, it is always recommended to consult the manufacturer’s guidelines and follow proper safety precautions when working with batteries.

2. How often should I measure the internal resistance of my batteries?

The frequency of internal resistance measurements depends on the application and the criticality of the battery’s performance. For example, in industrial settings or mission-critical applications, batteries may be tested daily or weekly to ensure they are in good health. For consumer electronics, it may be sufficient to test the battery every few months or when performance issues are noticed.

3. Can I use a multimeter to measure battery internal resistance?

Most standard multimeters do not have the capability to measure internal resistance directly. However, some advanced multimeters may have a built-in function for measuring battery internal resistance using the DC load test method. Always refer to the multimeter’s user manual to determine its capabilities and measurement procedures.

4. What should I do if I measure high internal resistance in my battery?

If you measure abnormally high internal resistance in your battery, first confirm the measurement using multiple methods if possible. If the high resistance is confirmed, the battery may need to be replaced. High internal resistance can lead to reduced performance, overheating, and potential safety issues. Always follow the manufacturer’s recommendations and dispose of old batteries properly.

5. Can I improve the internal resistance of a degraded battery?

In most cases, it is not possible to significantly improve the internal resistance of a degraded battery. Once a battery has reached the end of its useful life, the internal resistance will typically remain high due to irreversible chemical and structural changes. The best solution is to replace the battery with a new one that meets the manufacturer’s specifications.

Conclusion

Measuring the internal resistance of a battery is a crucial aspect of ensuring its performance, efficiency, and safety. By understanding the factors that influence internal resistance and the methods for measuring it, you can effectively monitor the health of your batteries and make informed decisions about when to replace them.

Remember to always follow proper safety procedures and consult manufacturer guidelines when working with batteries. Regular internal resistance measurements can help you optimize battery performance, extend battery life, and prevent potential issues before they become serious problems.

No responses yet