Introduction to Transformerless Power Supply

Transformerless power supplies have gained popularity in recent years due to their cost-effectiveness and space-saving design. Unlike traditional power supplies that rely on bulky transformers, transformerless power supplies utilize advanced electronic circuits to convert AC mains voltage into the desired DC voltage. This article will delve into the concept of transformerless power supplies, their advantages, working principles, applications, and important considerations when designing and using them.

Advantages of Transformerless Power Supplies

Cost Reduction

One of the primary advantages of transformerless power supplies is their cost-effectiveness. By eliminating the need for a transformer, which is often the most expensive component in a power supply, manufacturers can significantly reduce the overall cost of the unit. This cost reduction makes transformerless power supplies an attractive option for various applications, especially in mass-produced consumer electronics.

Space Saving

Transformers are not only expensive but also bulky and heavy. By removing the transformer from the power supply design, transformerless power supplies offer a more compact and lightweight solution. This space-saving aspect is particularly beneficial in applications where size and weight are critical factors, such as in portable devices, slim LED lighting fixtures, and space-constrained electronic equipment.

Improved Efficiency

Transformerless power supplies can achieve higher efficiency compared to transformer-based power supplies. Transformers inherently have losses due to factors like core losses and winding resistance. By eliminating the transformer, transformerless power supplies can minimize these losses and achieve better overall efficiency. Higher efficiency translates to reduced power consumption and heat generation, which can further contribute to the reliability and longevity of the power supply.

Working Principles of Transformerless Power Supplies

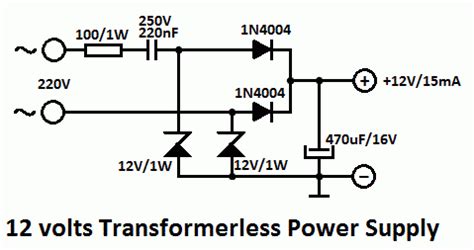

Voltage Rectification

The first stage in a transformerless power supply is voltage rectification. The AC mains voltage is rectified using a bridge rectifier, which converts the alternating current into pulsating direct current. The rectified voltage is then smoothed using capacitors to reduce the ripple and provide a more stable DC voltage.

Voltage Regulation

To obtain the desired DC output voltage, transformerless power supplies employ voltage regulation techniques. One common method is the use of a switching regulator, such as a buck converter or a Flyback Converter. These regulators use high-frequency switching to step down the rectified voltage to the required level. The switching frequency is typically in the range of tens to hundreds of kilohertz, which allows for smaller inductors and capacitors to be used, further contributing to the compact size of the power supply.

Isolation and Safety Considerations

Since transformerless power supplies do not have the inherent isolation provided by a transformer, special considerations must be taken to ensure electrical safety. Isolation techniques, such as optocouplers or isolation capacitors, are employed to provide galvanic isolation between the input and output stages of the power supply. Additionally, proper grounding and protective measures, such as fuses and surge suppressors, are implemented to prevent electrical shocks and protect the connected equipment.

Applications of Transformerless Power Supplies

LED Lighting

Transformerless power supplies are widely used in LED lighting applications. LED drivers based on transformerless designs offer a compact and efficient solution for powering LED lamps and fixtures. The absence of a transformer allows for slimmer and more lightweight LED drivers, making them suitable for integration into various lighting fixtures, such as downlights, panel lights, and linear lighting.

Consumer Electronics

Transformerless power supplies are commonly found in consumer electronic devices, such as televisions, computer monitors, and audio equipment. The cost and space savings provided by transformerless designs enable manufacturers to create more affordable and compact products. Additionally, the higher efficiency of transformerless power supplies contributes to reduced power consumption and improved energy efficiency ratings for these devices.

Industrial Applications

In industrial settings, transformerless power supplies find applications in control systems, automation equipment, and process instrumentation. The compact size and high efficiency of transformerless power supplies make them suitable for powering sensors, controllers, and communication devices in industrial environments. The absence of a transformer also reduces the overall weight of the equipment, making it easier to install and maintain.

Design Considerations for Transformerless Power Supplies

Input Voltage Range

When designing a transformerless power supply, it is important to consider the input voltage range. The power supply should be able to handle variations in the AC mains voltage, typically between 90V to 265V, to ensure reliable operation across different regions and power grid conditions. The rectification and voltage regulation stages must be designed to accommodate this wide input voltage range.

Output Voltage and Current

The output voltage and current requirements of the connected load must be carefully considered when designing a transformerless power supply. The voltage regulation stage should be designed to provide a stable and accurate output voltage, while the current rating should be sufficient to meet the maximum current demand of the load. Proper sizing of components, such as capacitors and inductors, is crucial to ensure reliable operation and minimize voltage ripple.

Electromagnetic Compatibility (EMC)

Transformerless power supplies generate high-frequency switching noise due to the use of switching regulators. This noise can cause electromagnetic interference (EMI) and affect the operation of nearby electronic devices. To mitigate EMI, proper filtering and shielding techniques must be employed. Common EMI suppression methods include the use of input and output filters, ferrite beads, and proper PCB layout techniques to minimize the coupling of high-frequency noise.

Thermal Management

Efficient thermal management is essential for the reliable operation of transformerless power supplies. The absence of a transformer reduces the overall heat generation, but the high-frequency switching components still generate heat that needs to be dissipated effectively. Proper heat sinking and airflow design are necessary to ensure that the components operate within their specified temperature ranges. Thermal simulations and testing can help optimize the thermal design and prevent overheating issues.

Future Trends in Transformerless Power Supplies

Integration of Smart Features

With the advancement of digital control and communication technologies, transformerless power supplies are increasingly incorporating smart features. These features may include real-time monitoring, remote control, and intelligent power management. By integrating microcontrollers or communication interfaces, transformerless power supplies can provide valuable data on power consumption, efficiency, and fault conditions, enabling better system management and maintenance.

Resonant Topologies

Resonant topologies, such as LLC resonant converters, are gaining traction in transformerless power supply designs. Resonant topologies offer several advantages, including soft switching, reduced switching losses, and higher efficiency. By operating at the resonant frequency, these topologies can achieve zero-voltage switching (ZVS) or zero-current switching (ZCS), minimizing the stress on the switching components and enabling higher power densities.

Wide Bandgap Semiconductors

The adoption of wide bandgap semiconductors, such as gallium nitride (GaN) and silicon carbide (SiC), is expected to revolutionize transformerless power supply designs. These materials offer superior switching characteristics, allowing for higher switching frequencies and reduced switching losses. The use of GaN and SiC devices can lead to even more compact and efficient transformerless power supplies, pushing the boundaries of power density and performance.

Frequently Asked Questions (FAQ)

1. Are transformerless power supplies safe to use?

Yes, transformerless power supplies can be safe to use when designed and implemented properly. However, since they lack the inherent isolation provided by a transformer, extra care must be taken to ensure proper isolation and safety measures are in place. This includes using isolation techniques, proper grounding, and protective devices like fuses and surge suppressors.

2. Can transformerless power supplies be used for high-power applications?

Transformerless power supplies are commonly used in low to medium power applications, typically up to a few hundred watts. For higher power levels, transformer-based power supplies are still more prevalent due to their ability to handle higher voltages and currents. However, with advancements in semiconductor technology and resonant topologies, transformerless power supplies are gradually making inroads into higher power applications.

3. How do transformerless power supplies achieve isolation without a transformer?

Transformerless power supplies employ various isolation techniques to provide galvanic isolation between the input and output stages. Some common methods include using optocouplers, which use light to transfer signals while maintaining electrical isolation, and isolation capacitors, which provide capacitive coupling while blocking direct current. These techniques ensure that there is no direct electrical connection between the input and output, enhancing safety.

4. What are the challenges in designing transformerless power supplies?

Designing transformerless power supplies presents several challenges. One key challenge is achieving proper isolation and safety without the use of a transformer. Designers must carefully select and implement isolation techniques to ensure compliance with safety standards. Another challenge is managing electromagnetic compatibility (EMC) and minimizing electromagnetic interference (EMI) generated by the high-frequency switching components. Proper filtering, shielding, and layout techniques are essential to mitigate EMI issues.

5. Are transformerless power supplies more energy-efficient than transformer-based power supplies?

Yes, transformerless power supplies can achieve higher energy efficiency compared to transformer-based power supplies. By eliminating the transformer, which inherently has losses, transformerless power supplies can minimize power losses and improve overall efficiency. The use of high-frequency switching regulators and advanced control techniques further contributes to enhanced efficiency. However, it’s important to note that the actual efficiency depends on the specific design and components used in the power supply.

Conclusion

Transformerless power supplies offer a cost-effective and space-saving solution for various applications, ranging from LED lighting to consumer electronics and industrial equipment. By eliminating the need for a bulky transformer, transformerless power supplies enable more compact and lightweight designs while achieving higher efficiency and reduced power consumption. However, designing transformerless power supplies requires careful consideration of isolation, safety, and electromagnetic compatibility aspects to ensure reliable and safe operation.

As technology advances, transformerless power supplies are expected to incorporate smart features, leverage resonant topologies, and adopt wide bandgap semiconductors to further enhance performance and power density. These advancements will continue to drive the adoption of transformerless power supplies in new applications and push the boundaries of what is possible in terms of size, efficiency, and functionality.

By understanding the principles, advantages, and design considerations of transformerless power supplies, engineers and manufacturers can make informed decisions when selecting and implementing power supply solutions for their projects. The transformerless approach offers a compelling alternative to traditional transformer-based power supplies, enabling the development of more compact, cost-effective, and energy-efficient electronic devices.

No responses yet