Understanding the Basics of PCB Mount Transformers

Before diving into the selection process, it’s important to understand the fundamental concepts and functions of PCB mount transformers.

What is a PCB Mount Transformer?

A PCB mount transformer is a type of transformer designed to be directly mounted on a printed circuit board (PCB). These transformers are typically smaller in size compared to their standalone counterparts, making them suitable for space-constrained applications. They are commonly used in power supplies, signal isolation, and impedance matching circuits.

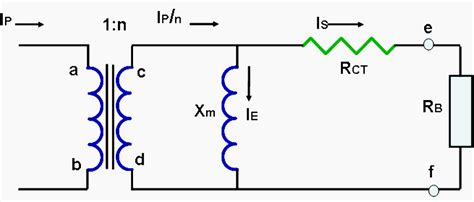

How Does a PCB Mount Transformer Work?

A PCB mount transformer operates on the principle of electromagnetic induction. It consists of two or more windings (primary and secondary) wound around a common magnetic core. When an alternating current (AC) is applied to the primary winding, it creates a magnetic flux in the core, which induces a voltage in the secondary winding. The voltage ratio between the primary and secondary windings depends on the number of turns in each winding.

Benefits of Using PCB Mount Transformers

PCB mount transformers offer several advantages over discrete transformers:

- Space Savings: Due to their compact size, PCB mount transformers help minimize the overall footprint of the circuit board.

- Ease of Assembly: These transformers can be easily soldered onto the PCB using standard surface-mount technology (SMT) processes.

- Reduced Wiring: With direct PCB mounting, the need for additional wiring is minimized, resulting in improved signal integrity and reduced electromagnetic interference (EMI).

- Cost-Effective: PCB mount transformers are generally more cost-effective compared to discrete transformers, especially in high-volume production.

Key Factors to Consider When Selecting a PCB Mount Transformer

When choosing a PCB mount transformer, several key factors need to be taken into account to ensure optimal performance and compatibility with your circuit design.

1. Power Rating and Voltage Requirements

The first step in selecting a PCB mount transformer is to determine the power rating and voltage requirements of your application. Consider the following aspects:

- Input Voltage Range: Identify the minimum and maximum input voltages that the transformer needs to handle.

- Output Voltage and Current: Specify the desired output voltage and current levels required by your circuit.

- Power Handling Capacity: Determine the maximum power that the transformer should be able to deliver based on your load requirements.

It’s important to choose a transformer with a power rating that exceeds your application’s demands to ensure reliable operation and prevent overloading.

2. Frequency Range and Core Material

The frequency range of your application plays a crucial role in selecting the appropriate transformer core material. Different core materials have varying properties that affect the transformer’s performance, efficiency, and frequency response.

Common core materials used in PCB mount transformers include:

- Ferrite: Ferrite cores are suitable for high-frequency applications (above 20 kHz) and offer low losses, high permeability, and good temperature stability.

- Laminated Steel: Laminated steel cores are commonly used for low-frequency applications (50/60 Hz) and provide high saturation flux density and good mechanical strength.

- Powdered Iron: Powdered iron cores are suitable for medium-frequency applications (up to a few hundred kHz) and offer high permeability, low losses, and good thermal stability.

Consider the frequency range of your application and choose a core material that offers the best performance and efficiency in that range.

3. Winding Configuration and Turns Ratio

The winding configuration and turns ratio of a PCB mount transformer determine the voltage transformation and isolation properties.

Winding configurations can be classified into two main categories:

- Primary-Secondary: This configuration consists of separate primary and secondary windings, providing galvanic isolation between the input and output.

- Auto-Transformer: In this configuration, a single winding is used with taps at different points, resulting in a non-isolated transformer.

The turns ratio, which is the ratio of the number of turns in the primary winding to the number of turns in the secondary winding, determines the voltage transformation. For example, a transformer with a turns ratio of 2:1 will step down the voltage by a factor of 2.

Choose the appropriate winding configuration and turns ratio based on your voltage transformation and isolation requirements.

4. Insulation Class and Dielectric Strength

Insulation class and dielectric strength are critical factors to consider when selecting a PCB mount transformer, especially in applications that require high voltage isolation or operate in harsh environments.

Insulation classes are categorized based on the maximum operating temperature of the transformer:

- Class A: 105°C

- Class B: 130°C

- Class F: 155°C

- Class H: 180°C

Select an insulation class that matches or exceeds the maximum expected operating temperature of your application to ensure long-term reliability.

Dielectric strength refers to the maximum voltage that the transformer’s insulation can withstand without breakdown. It is typically expressed in kV (kilovolts) and should be chosen based on the voltage levels present in your circuit and the required safety margins.

5. Mounting and Packaging Options

PCB mount transformers come in various mounting and packaging options to suit different PCB layouts and assembly processes.

Common mounting options include:

- Surface Mount (SMT): SMT transformers are designed for automated pick-and-place assembly and are suitable for high-volume production.

- Through-Hole (THT): THT transformers have leads that are inserted through holes in the PCB and soldered on the opposite side. They offer better mechanical stability but require manual assembly.

Packaging options for PCB mount transformers include:

- Tape and Reel: SMT transformers are often packaged in tape and reel format for automated assembly processes.

- Tube or Tray: THT transformers may be packaged in tubes or trays for manual assembly.

Consider your PCB layout, assembly process, and production volume when selecting the appropriate mounting and packaging options.

6. Shielding and EMI Considerations

In some applications, electromagnetic interference (EMI) can be a concern, especially in sensitive circuits or environments with strict EMC (electromagnetic compatibility) requirements. Shielded PCB mount transformers can help mitigate EMI issues.

Shielding options for PCB mount transformers include:

- Electrostatic Shielding: This type of shielding uses a conductive foil or screen between the primary and secondary windings to reduce capacitive coupling and common-mode noise.

- Magnetic Shielding: Magnetic shielding involves enclosing the transformer in a high-permeability material, such as mu-metal, to contain the magnetic field and reduce electromagnetic radiation.

Evaluate the EMI susceptibility of your application and choose a shielding option that provides adequate protection against interference.

Transformer Selection Based on Application Requirements

The selection of a PCB mount transformer depends on the specific requirements of your application. Here are some common applications and the key considerations for transformer selection:

Power Supplies

In power supply applications, PCB mount transformers are used for voltage step-up or step-down and isolation. Key considerations include:

- Power rating and efficiency

- Input and output voltage ranges

- Regulation and load requirements

- Safety standards and isolation voltage

| Parameter | Value |

|---|---|

| Input Voltage Range | 90-264 VAC |

| Output Voltage | 12 VDC |

| Output Current | 2 A |

| Power Rating | 24 W |

| Efficiency | >85% |

| Isolation Voltage | 3 kVAC |

| Safety Standards | UL, CE, TUV |

Signal Isolation

PCB mount transformers are commonly used for signal isolation to prevent ground loops, reduce noise, and protect sensitive circuits. Key considerations include:

- Frequency range and bandwidth

- Insertion loss and common-mode rejection ratio (CMRR)

- Isolation voltage and insulation resistance

- Impedance matching and termination

| Parameter | Value |

|---|---|

| Frequency Range | 100 kHz – 10 MHz |

| Insertion Loss | <1 dB |

| CMRR | >70 dB |

| Isolation Voltage | 2.5 kVAC |

| Insulation Resistance | >1000 MΩ |

| Impedance | 50 Ω |

Audio and Telecommunication

In audio and telecommunication applications, PCB mount transformers are used for impedance matching, balanced-to-unbalanced conversion, and line isolation. Key considerations include:

- Frequency response and distortion

- Power handling capacity and saturation

- Turns ratio and impedance matching

- Electrostatic shielding and common-mode rejection

| Parameter | Value |

|---|---|

| Frequency Response | 20 Hz – 20 kHz |

| Total Harmonic Distortion | <0.1% |

| Power Handling | 1 W |

| Turns Ratio | 1:1 |

| Impedance Ratio | 600 Ω : 600 Ω |

| Electrostatic Shielding | Yes |

| Common-Mode Rejection | >60 dB |

Frequently Asked Questions (FAQ)

-

Q: What is the difference between a PCB mount transformer and a discrete transformer?

A: PCB mount transformers are designed to be directly soldered onto a printed circuit board, while discrete transformers are standalone components that require additional wiring and mounting. PCB mount transformers are generally smaller in size and more cost-effective for high-volume production. -

Q: How do I determine the power rating of the transformer I need?

A: To determine the required power rating, calculate the maximum power consumption of your load by multiplying the voltage and current. Choose a transformer with a power rating that exceeds this value to ensure reliable operation and prevent overloading. -

Q: What is the difference between ferrite and laminated steel cores?

A: Ferrite cores are suitable for high-frequency applications (above 20 kHz) and offer low losses, high permeability, and good temperature stability. Laminated steel cores are commonly used for low-frequency applications (50/60 Hz) and provide high saturation flux density and good mechanical strength. -

Q: What is the purpose of electrostatic shielding in a transformer?

A: Electrostatic shielding helps reduce capacitive coupling and common-mode noise between the primary and secondary windings of a transformer. It is particularly important in applications sensitive to electromagnetic interference (EMI) or those requiring high isolation. -

Q: How do I choose the appropriate mounting option for my PCB mount transformer?

A: The choice between surface mount (SMT) and through-hole (THT) mounting depends on your PCB layout, assembly process, and production volume. SMT transformers are suitable for automated pick-and-place assembly and high-volume production, while THT transformers offer better mechanical stability but require manual assembly.

Conclusion

Selecting the right PCB mount transformer is crucial for ensuring optimal performance, efficiency, and reliability in your electronic circuits. By considering factors such as power rating, voltage requirements, frequency range, core material, winding configuration, insulation class, dielectric strength, mounting options, and shielding, you can make an informed decision that meets your application’s specific needs.

Remember to evaluate your application’s requirements carefully and consult transformer datasheets and application notes for detailed specifications and guidelines. Working with reputable manufacturers and suppliers can also help ensure the quality and reliability of the transformers you choose.

By following this comprehensive guide and understanding the key factors involved in transformer selection, you can confidently navigate the process of choosing the ideal PCB mount transformer for your next project.

No responses yet