Introduction to PCB Pins

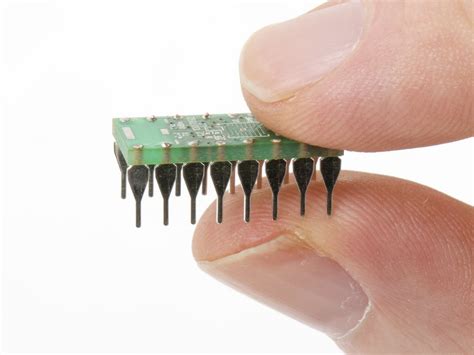

PCB pins, also known as printed circuit board pins, are essential components in electronic devices. They serve as the connection points between different parts of a circuit board, allowing electrical signals to flow through the device. PCB pins come in various shapes, sizes, and materials, each designed for specific applications.

In this comprehensive guide, we will explore the different types of PCB pins, their uses, and how to choose the right ones for your project. We will also discuss the latest trends and innovations in PCB pin technology.

Types of PCB Pins

There are several types of PCB pins available in the market, each with its own unique features and benefits. Here are some of the most common types of PCB pins:

Through-Hole Pins

Through-hole pins are the most traditional type of PCB pins. They are inserted into drilled holes on the circuit board and soldered in place. Through-hole pins are known for their strong mechanical connection and are often used in high-reliability applications such as aerospace and military equipment.

Surface Mount Pins

Surface mount pins, also known as SMT pins, are designed to be soldered directly onto the surface of the circuit board. They are smaller and more compact than through-hole pins, making them ideal for high-density applications. SMT pins are commonly used in consumer electronics, such as smartphones and laptops.

Press-Fit Pins

Press-fit pins are designed to be inserted into plated through-holes on the circuit board without the need for soldering. They have a compliant section that compresses when inserted, creating a secure mechanical and electrical connection. Press-fit pins are often used in automotive and industrial applications where reliability is critical.

Wire-Wrap Pins

Wire-wrap pins are designed for prototyping and low-volume production. They have a square post that allows wires to be wrapped around them, creating a temporary electrical connection. Wire-wrap pins are often used in breadboarding and testing applications.

Choosing the Right PCB Pins

When selecting PCB pins for your project, there are several factors to consider. Here are some of the most important ones:

Material

PCB pins are available in various materials, including brass, phosphor bronze, and beryllium copper. Each material has its own unique properties, such as conductivity, durability, and cost. Choose the material that best suits your application and budget.

Plating

PCB pins are often plated with various metals to improve their conductivity and durability. Common plating materials include gold, tin, and nickel. Gold plating is often used in high-reliability applications, while tin plating is more cost-effective for consumer electronics.

Size and Shape

PCB pins come in various sizes and shapes, depending on the application. Through-hole pins are available in different diameters and lengths, while SMT pins can have various shapes such as gull-wing, J-lead, and I-lead. Choose the size and shape that best fits your circuit board layout and assembly process.

Current Rating

The current rating of a PCB pin determines how much current it can handle without overheating or failing. Choose a pin with a current rating that exceeds the maximum current expected in your application, with some margin for safety.

Latest Trends in PCB Pin Technology

PCB pin technology is constantly evolving to meet the demands of new applications and manufacturing processes. Here are some of the latest trends in PCB pin technology:

High-Speed Pins

As electronic devices become faster and more complex, the demand for high-speed PCB pins is increasing. High-speed pins are designed to minimize signal distortion and crosstalk, allowing for faster data transfer rates. They often have special features such as impedance matching and shielding.

Miniaturization

The trend towards miniaturization in electronics is driving the development of smaller and more compact PCB pins. Micro-pins and nano-pins are becoming increasingly popular in applications such as wearables and medical devices.

3D Printing

3D printing technology is being used to create custom PCB pins for specific applications. This allows for greater design flexibility and faster prototyping times. 3D printed pins can also have unique shapes and features that are not possible with traditional manufacturing methods.

Applications of PCB Pins

PCB pins are used in a wide range of electronic devices and applications. Here are some of the most common ones:

Consumer Electronics

PCB pins are used extensively in consumer electronics such as smartphones, tablets, and laptops. They provide the electrical connections between the various components on the circuit board, such as the processor, memory, and display.

Automotive Electronics

PCB pins are used in various automotive electronics applications, such as engine control units, infotainment systems, and advanced driver assistance systems (ADAS). They must be able to withstand harsh environmental conditions such as extreme temperatures, vibration, and moisture.

Industrial Automation

PCB pins are used in industrial automation equipment such as programmable logic controllers (PLCs), sensors, and actuators. They must be reliable and durable to ensure the smooth operation of the equipment.

Medical Devices

PCB pins are used in various medical devices such as pacemakers, insulin pumps, and diagnostic equipment. They must meet strict regulatory requirements for safety and reliability.

Frequently Asked Questions

Q: What is the difference between through-hole and surface mount pins?

A: Through-hole pins are inserted into drilled holes on the circuit board and soldered in place, while surface mount pins are soldered directly onto the surface of the board. Through-hole pins provide a stronger mechanical connection, while surface mount pins are smaller and more compact.

Q: What materials are PCB pins made of?

A: PCB pins are typically made of brass, phosphor bronze, or beryllium copper. Each material has its own unique properties such as conductivity, durability, and cost.

Q: How do I choose the right PCB pins for my application?

A: When choosing PCB pins, consider factors such as the material, plating, size and shape, and current rating. Choose pins that meet the specific requirements of your application and manufacturing process.

Q: What are the latest trends in PCB pin technology?

A: Some of the latest trends in PCB pin technology include high-speed pins for faster data transfer rates, miniaturization for smaller and more compact devices, and 3D printing for custom pin designs.

Q: What industries use PCB pins?

A: PCB pins are used in a wide range of industries, including consumer electronics, automotive, industrial automation, and medical devices. They provide the essential electrical connections that allow these devices to function properly.

Conclusion

PCB pins are a critical component in electronic devices, providing the essential electrical connections that allow them to function properly. With the wide range of types, materials, and sizes available, it is important to choose the right PCB pins for your specific application and manufacturing process.

By staying up-to-date with the latest trends in PCB pin technology, such as high-speed pins, miniaturization, and 3D printing, you can ensure that your electronic devices are using the most advanced and reliable components available.

Whether you are designing consumer electronics, automotive systems, industrial automation equipment, or medical devices, understanding the basics of PCB pins and how to use them effectively is essential for creating reliable and high-performing electronic products.

| Type of Pin | Description | Common Applications |

|---|---|---|

| Through-Hole | Inserted into drilled holes and soldered in place; strong mechanical connection | High-reliability applications (aerospace, military) |

| Surface Mount | Soldered directly onto the surface of the board; smaller and more compact | Consumer electronics (smartphones, laptops) |

| Press-Fit | Inserted into plated through-holes without soldering; secure mechanical and electrical connection | Automotive and industrial applications |

| Wire-Wrap | Square post allows wires to be wrapped around for temporary electrical connection | Prototyping and low-volume production |

No responses yet