Understanding PCB Silkscreen

What is PCB Silkscreen?

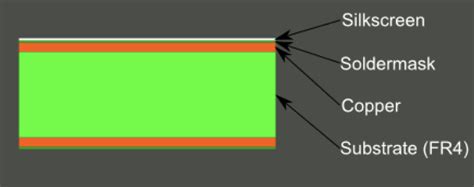

PCB silkscreen, also known as legend or nomenclature, is the text and symbols printed on the surface of a PCB. It provides essential information about the components, their placement, and the overall layout of the board. The silkscreen is typically white, although other colors may be used for specific applications or to enhance visibility.

The Importance of PCB Silkscreen

A well-designed and properly applied PCB silkscreen offers several benefits:

- Assists in component placement during assembly

- Facilitates testing and troubleshooting

- Improves the overall aesthetics of the PCB

- Provides valuable information for future maintenance or modifications

Designing Your PCB Silkscreen

Choosing the Right Software

To create a high-quality PCB silkscreen, you need to use the right design software. Some popular options include:

- Altium Designer

- KiCad

- Eagle CAD

- OrCAD

These software packages offer a range of features and capabilities, allowing you to create detailed and accurate silkscreen designs.

Best Practices for Silkscreen Design

When designing your PCB silkscreen, keep the following best practices in mind:

- Use clear and legible fonts

- Maintain adequate spacing between components and text

- Avoid placing text or symbols over pads or traces

- Use consistent and standardized nomenclature

- Keep the silkscreen design simple and clutter-free

Creating a Silkscreen Legend

A silkscreen legend is a table or list that explains the meaning of the various symbols and abbreviations used in your silkscreen design. It should be included in your PCB Documentation to ensure that anyone working with the board can easily understand the silkscreen.

| Symbol | Meaning |

|---|---|

| R1, R2 | Resistors |

| C1, C2 | Capacitors |

| D1, D2 | Diodes |

| IC1, IC2 | Integrated Circuits |

| GND | Ground |

| VCC | Positive Supply Voltage |

Manufacturing Your PCB Silkscreen

Choosing a PCB Manufacturer

When selecting a PCB manufacturer, consider the following factors:

- Experience and reputation

- Quality control processes

- Turnaround time

- Pricing

- Customer support

A reputable PCB manufacturer will ensure that your silkscreen is applied correctly and meets your specifications.

Silkscreen Application Methods

There are two primary methods for applying silkscreen to a PCB:

- Screen printing

- A stencil is created with the silkscreen design

- Ink is pushed through the stencil onto the PCB surface

- Provides a durable and long-lasting silkscreen

- Direct legend printing

- The silkscreen design is printed directly onto the PCB surface using a specialized printer

- Offers higher resolution and finer details compared to screen printing

- Suitable for small text and intricate designs

Your PCB manufacturer will recommend the best application method based on your design requirements and the specific capabilities of their equipment.

Quality Control and Inspection

To ensure that your PCB silkscreen meets your expectations, it is essential to have a thorough quality control and inspection process in place. This may include:

- Visual inspection for legibility, alignment, and completeness

- Automated optical inspection (AOI) to detect any defects or inconsistencies

- Functional testing to verify that the silkscreen does not interfere with the PCB’s operation

Your PCB manufacturer should provide a detailed quality control report along with your completed boards.

Troubleshooting Common Silkscreen Issues

Despite careful design and manufacturing, issues may arise with your PCB silkscreen. Some common problems and their solutions include:

- Illegible or incomplete text

- Ensure that the font size is appropriate for the available space

- Check the silkscreen design for any missing or overlapping elements

- Verify that the silkscreen application method is suitable for your design

- Misaligned or offset silkscreen

- Confirm that the silkscreen design is properly aligned with the PCB layout

- Check the manufacturing process for any issues with the stencil or printing equipment

- Consider using fiducial marks to improve alignment accuracy

- Silkscreen interfering with components or traces

- Review the silkscreen design to ensure adequate clearance around components and traces

- Adjust the placement of text and symbols to avoid any conflicts

- Consider using a different color or application method to improve visibility and avoid interference

By addressing these issues promptly and working closely with your PCB manufacturer, you can ensure that your PCB silkscreen meets your quality and functional requirements.

Frequently Asked Questions (FAQ)

- What is the minimum font size for PCB silkscreen?

-

The minimum font size depends on the application method and the specific capabilities of your PCB manufacturer. Generally, a font size of 0.8mm to 1.0mm is recommended for good legibility.

-

Can I use colors other than white for my PCB silkscreen?

-

Yes, other colors such as yellow, red, or black can be used for PCB silkscreen. However, white is the most common color as it provides the best contrast and legibility against the typical green or black PCB substrate.

-

How can I ensure that my silkscreen design is compatible with my PCB layout?

-

Use your PCB design software to create a combined view of your silkscreen and PCB layout. This will allow you to check for any conflicts or overlaps between the silkscreen and components or traces.

-

What is the typical turnaround time for PCB silkscreen application?

-

The turnaround time depends on the complexity of your design, the chosen application method, and the workload of your PCB manufacturer. Generally, expect a turnaround time of 1-2 weeks for standard PCB silkscreen orders.

-

Can I remove or modify the silkscreen on an existing PCB?

- Removing or modifying silkscreen on an existing PCB is possible but can be challenging. Mechanical abrasion or chemical solvents may be used to remove the existing silkscreen, after which a new silkscreen can be applied. However, this process may damage the PCB if not done carefully, so it is recommended to consult with a professional PCB rework service.

By following this step-by-step guide and working closely with a reputable PCB manufacturer, you can achieve a high-quality and satisfactory PCB silkscreen that enhances the functionality and aesthetics of your printed circuit board.

No responses yet