Introduction to MOSFETs

Metal-Oxide-Semiconductor Field-Effect Transistors (MOSFETs) are widely used semiconductor devices in modern electronics. They are essential components in various applications, including power electronics, analog circuits, and digital logic. Understanding how to test a MOSFET is crucial for engineers, technicians, and hobbyists working with these devices.

In this comprehensive article, we will guide you through the process of effectively testing a MOSFET. We will cover the basics of MOSFET operation, the different types of MOSFETs, and the various testing methods used to determine their functionality and performance.

Understanding MOSFET Basics

Before diving into the testing procedures, it is essential to understand the fundamental principles of MOSFET operation. MOSFETs are voltage-controlled devices that use an electric field to control the flow of current between the source and drain terminals. The gate terminal acts as the control input, regulating the conductivity of the channel between the source and drain.

MOSFET Structure and Operation

A MOSFET consists of three main terminals: the gate, source, and drain. The gate is electrically isolated from the channel by a thin layer of insulating material, typically silicon dioxide (SiO2). When a voltage is applied to the gate, it creates an electric field that attracts or repels charge carriers (electrons or holes) in the channel, modulating its conductivity.

N-Channel and P-Channel MOSFETs

MOSFETs come in two primary types: N-channel and P-channel. The type of MOSFET is determined by the doping of the semiconductor material used in the channel.

- N-Channel MOSFETs: In an N-channel MOSFET, the channel is formed by the flow of electrons. When a positive voltage is applied to the gate, it attracts electrons to the channel, allowing current to flow between the source and drain.

- P-Channel MOSFETs: In a P-channel MOSFET, the channel is formed by the flow of holes (positive charge carriers). When a negative voltage is applied to the gate, it attracts holes to the channel, allowing current to flow between the source and drain.

Enhancement-Mode and Depletion-Mode MOSFETs

MOSFETs can also be categorized based on their mode of operation: enhancement-mode and depletion-mode.

- Enhancement-Mode MOSFETs: In an enhancement-mode MOSFET, the channel is initially non-conductive. A voltage applied to the gate enhances the conductivity of the channel, allowing current to flow between the source and drain.

- Depletion-Mode MOSFETs: In a depletion-mode MOSFET, the channel is initially conductive. A voltage applied to the gate depletes the channel of charge carriers, reducing or stopping the flow of current between the source and drain.

Testing Methods for MOSFETs

There are several methods to test a MOSFET, each focusing on different aspects of the device’s functionality and performance. Let’s explore some of the most common testing methods.

Visual Inspection

Before conducting any electrical tests, it is essential to perform a visual inspection of the MOSFET. Check for any physical damage, such as cracks, burns, or broken leads. Ensure that the device is clean and free from any debris or contamination.

Continuity Test

A continuity test is a simple method to check for short circuits or open circuits within the MOSFET. Using a multimeter set to the continuity or resistance mode, follow these steps:

- Identify the MOSFET’s pinout (source, drain, and gate) using the device’s datasheet.

- Test for shorts between the gate and source, gate and drain, and source and drain. The multimeter should indicate an open circuit (high resistance) for all three combinations.

- Test for continuity between the source and drain. The multimeter should indicate a high resistance when the gate is not biased and a low resistance when the gate is biased (for an enhancement-mode MOSFET).

Threshold Voltage Test

The threshold voltage (Vth) is the minimum gate-to-source voltage required to turn on the MOSFET and allow current to flow between the source and drain. Testing the threshold voltage helps determine if the MOSFET is functioning correctly and meets the manufacturer’s specifications.

To test the threshold voltage, follow these steps:

- Set up a test circuit with the MOSFET, a variable voltage source for the gate, and a fixed voltage source for the drain.

- Gradually increase the gate voltage while monitoring the drain current using a multimeter or oscilloscope.

- Record the gate voltage at which the drain current starts to increase significantly. This voltage is the threshold voltage.

- Compare the measured threshold voltage with the value specified in the MOSFET’s datasheet to ensure it falls within the acceptable range.

Drain Current Test

Testing the drain current (Id) helps evaluate the MOSFET’s ability to conduct current and its performance under different bias conditions. To test the drain current, follow these steps:

- Set up a test circuit with the MOSFET, a variable voltage source for the gate, and a variable voltage source for the drain.

- Apply a fixed gate voltage above the threshold voltage to turn on the MOSFET.

- Vary the drain voltage and measure the corresponding drain current using a multimeter or oscilloscope.

- Plot the drain current versus drain voltage characteristics and compare them with the graphs provided in the MOSFET’s datasheet.

Breakdown Voltage Test

The breakdown voltage is the maximum voltage that can be applied between the drain and source before the MOSFET suffers permanent damage. Testing the breakdown voltage helps ensure that the MOSFET can withstand the expected voltage levels in the target application.

To test the breakdown voltage, follow these steps:

- Set up a test circuit with the MOSFET, a variable high-voltage source for the drain, and the gate and source connected to ground.

- Gradually increase the drain voltage while monitoring the drain current.

- Record the voltage at which the drain current starts to increase rapidly, indicating the onset of breakdown.

- Compare the measured breakdown voltage with the value specified in the MOSFET’s datasheet to ensure it meets the required specifications.

Caution: Breakdown voltage tests involve high voltages and can potentially damage the MOSFET. Exercise extreme caution and follow proper safety procedures when conducting these tests.

Switching Characteristics Test

Testing the switching characteristics of a MOSFET is essential for applications that involve high-speed switching, such as power converters and digital circuits. The key parameters to evaluate are the turn-on and turn-off times, rise and fall times, and propagation delay.

To test the switching characteristics, follow these steps:

- Set up a test circuit with the MOSFET, a Pulse Generator for the gate, and a load resistor connected to the drain.

- Apply a square wave signal to the gate, with the amplitude exceeding the threshold voltage and the frequency and duty cycle appropriate for the target application.

- Use an oscilloscope to capture the waveforms at the gate and drain terminals.

- Measure the turn-on and turn-off times, rise and fall times, and propagation delay from the captured waveforms.

- Compare the measured values with the specifications provided in the MOSFET’s datasheet to ensure they meet the required performance criteria.

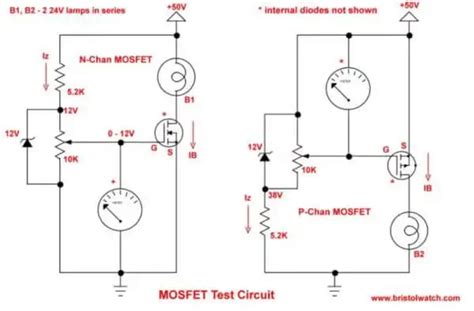

MOSFET Test Circuits

To facilitate MOSFET testing, several common test circuits can be used. These circuits provide a standardized setup for evaluating the device’s characteristics and performance.

Basic MOSFET Test Circuit

A basic MOSFET test circuit consists of the following components:

– MOSFET under test

– Variable voltage source for the gate (Vgs)

– Variable voltage source for the drain (Vds)

– Current-Limiting Resistor (Rg) connected to the gate

– Load resistor (Rd) connected to the drain

– Multimeter or oscilloscope for measuring voltage and current

The circuit allows for the measurement of various parameters, such as threshold voltage, drain current, and on-resistance.

MOSFET Switching Test Circuit

A MOSFET switching test circuit is used to evaluate the device’s switching performance. The circuit typically includes:

– MOSFET under test

– Pulse generator for the gate

– Load resistor (Rd) connected to the drain

– Oscilloscope for capturing the gate and drain waveforms

By applying a square wave signal to the gate and observing the drain waveform, the switching characteristics can be determined.

MOSFET Breakdown Voltage Test Circuit

A breakdown voltage test circuit is used to measure the maximum voltage a MOSFET can withstand before suffering permanent damage. The circuit includes:

– MOSFET under test

– High-voltage variable source connected to the drain

– Current-limiting resistor (Rd) connected to the drain

– Multimeter or oscilloscope for measuring voltage and current

The gate and source terminals are typically connected to ground during the breakdown voltage test.

MOSFET Test Equipment

To conduct effective MOSFET tests, certain equipment is essential. The following table lists the common test equipment used for MOSFET characterization:

| Equipment | Purpose |

|---|---|

| Multimeter | Measuring voltage, current, and resistance |

| Oscilloscope | Capturing and analyzing waveforms |

| Power Supply | Providing stable and adjustable voltage sources |

| Function Generator | Generating input signals for switching tests |

| Curve Tracer | Plotting I-V characteristics and measuring parameters |

In addition to the equipment mentioned above, a well-equipped electronics lab should also have a variety of MOSFET test fixtures, probes, and adapters to facilitate reliable and efficient testing.

MOSFET Testing Best Practices

To ensure accurate and reliable MOSFET testing results, consider the following best practices:

- Always refer to the MOSFET’s datasheet for the device’s specifications, pinout, and recommended operating conditions.

- Use appropriate test equipment that meets the required accuracy and resolution for the parameters being measured.

- Ensure proper grounding and shielding techniques to minimize noise and interference during testing.

- Exercise caution when handling MOSFETs, especially during high-voltage tests, to prevent damage to the device and ensure personal safety.

- Maintain a clean and static-free work environment to prevent contamination and electrostatic discharge (ESD) damage to the MOSFETs.

- Document the test setup, conditions, and results for future reference and reproducibility.

Troubleshooting Common MOSFET Issues

During MOSFET testing, you may encounter various issues that can affect the device’s performance or lead to incorrect test results. Here are some common problems and their potential solutions:

-

Problem: MOSFET fails the continuity test, indicating a short circuit between terminals.

Solution: The MOSFET may be damaged or defective. Replace the device with a new one and retest. -

Problem: Measured threshold voltage is significantly different from the datasheet value.

Solution: Verify the test setup and ensure proper connections. If the issue persists, the MOSFET may be faulty or damaged. -

Problem: Drain current is lower than expected or the MOSFET fails to turn on.

Solution: Check the gate voltage and ensure it exceeds the threshold voltage. Verify the test circuit connections and the integrity of the MOSFET’s package and leads. -

Problem: Breakdown voltage is lower than the specified value.

Solution: The MOSFET may have been exposed to excessive voltage or current, causing permanent damage. Replace the device and ensure proper handling and protection during testing. -

Problem: Switching characteristics do not meet the required specifications.

Solution: Verify the test circuit and ensure proper loading conditions. Check the gate drive signal for the correct amplitude, frequency, and rise/fall times. If the issue persists, the MOSFET may not be suitable for the target application.

Conclusion

Testing MOSFETs is a critical skill for anyone working with power electronics, analog circuits, or digital systems. By understanding the different types of MOSFETs, their operating principles, and the various testing methods, you can effectively characterize and troubleshoot these devices.

Remember to follow best practices, use appropriate test equipment, and always refer to the MOSFET’s datasheet for accurate specifications and guidelines. With the knowledge gained from this article, you are now well-equipped to conduct effective MOSFET tests and ensure the reliability and performance of your electronic designs.

Frequently Asked Questions (FAQ)

-

Q: What is the difference between an N-channel and P-channel MOSFET?

A: N-channel MOSFETs use electrons as the majority charge carriers, while P-channel MOSFETs use holes. N-channel MOSFETs turn on with a positive gate voltage, while P-channel MOSFETs turn on with a negative gate voltage. -

Q: How do I identify the pinout of a MOSFET?

A: The pinout of a MOSFET can be determined by referring to the device’s datasheet. The datasheet will provide a diagram showing the location and designation of each pin (gate, source, and drain). -

Q: What is the purpose of the threshold voltage in a MOSFET?

A: The threshold voltage (Vth) is the minimum gate-to-source voltage required to turn on the MOSFET and allow current to flow between the source and drain. It determines the point at which the MOSFET starts to conduct. -

Q: Can I test a MOSFET without removing it from the circuit?

A: In-circuit testing of MOSFETs is possible, but it can be challenging due to the influence of other components in the circuit. It is recommended to isolate the MOSFET or use dedicated test points to minimize the impact of surrounding components on the test results. -

Q: What safety precautions should I take when testing MOSFETs?

A: When testing MOSFETs, always follow proper safety procedures, especially when dealing with high voltages. Use appropriate test equipment, wear protective gear (e.g., safety glasses, gloves), and ensure proper grounding and isolation. Be cautious of electrostatic discharge (ESD) and handle MOSFETs with care to prevent damage.

No responses yet