Introduction to SMD Capacitor Codes

Surface-mount device (SMD) capacitors are essential components in modern electronic circuits. These tiny components are marked with codes that provide crucial information about their capacitance, tolerance, and voltage rating. Understanding how to read and interpret these codes is vital for anyone working with electronic components, whether you’re a hobbyist, a student, or a professional engineer.

In this comprehensive guide, we’ll dive deep into the world of SMD capacitor codes, explaining their structure, the different coding systems used, and how to decipher them accurately. By the end of this article, you’ll be able to confidently identify and select the right SMD capacitor for your project.

The Importance of SMD Capacitor Codes

SMD capacitors are ubiquitous in modern electronics due to their small size, high performance, and ease of automated assembly. However, their miniature size also means that there’s limited space for marking them with their specifications. This is where SMD capacitor codes come into play.

These codes are printed on the surface of the capacitor and provide essential information about the component’s characteristics. Being able to read and understand these codes is crucial for several reasons:

-

Identification: SMD capacitor codes allow you to quickly identify the capacitance, tolerance, and voltage rating of a component, even when it’s not in its original packaging.

-

Selection: When designing or repairing a circuit, you need to choose the right capacitor for the job. Knowing how to interpret SMD capacitor codes ensures that you select a component with the correct specifications.

-

Troubleshooting: If a circuit isn’t functioning as expected, being able to read SMD capacitor codes can help you determine whether a capacitor is the culprit and needs to be replaced.

-

Inventory management: For those who maintain an inventory of electronic components, understanding SMD capacitor codes makes it easier to organize and keep track of your stock.

Common SMD Capacitor Coding Systems

There are several coding systems used for SMD capacitors, each with its own set of rules and conventions. The most common ones are:

-

EIA-96 Standard: This coding system uses a combination of letters and numbers to represent the capacitance and tolerance of a capacitor. It’s widely used for ceramic and tantalum capacitors.

-

Metric Coding: Also known as the “European” coding system, metric coding uses a combination of numbers and letters to indicate the capacitance and tolerance. It’s commonly used for film and aluminum electrolytic capacitors.

-

Manufacturer-Specific Codes: Some capacitor manufacturers use their own proprietary coding systems, which may deviate from the industry standards. In these cases, it’s essential to refer to the manufacturer’s documentation to decode the capacitor’s specifications.

In the following sections, we’ll take a closer look at each of these coding systems and provide examples of how to read and interpret them.

EIA-96 Standard Coding System

The EIA-96 standard, developed by the Electronic Industries Alliance (EIA), is one of the most widely used coding systems for SMD capacitors. It employs a combination of two letters and a number to represent the capacitance and tolerance of a capacitor.

Capacitance Code

The capacitance code consists of two letters, each representing a digit from 0 to 9. The first letter represents the first and second significant digits of the capacitance value, while the second letter represents the multiplier.

Here’s the table for the first letter:

| Letter | Significant Digits |

|---|---|

| A | 10 |

| B | 11 |

| C | 12 |

| D | 13 |

| E | 14 |

| F | 15 |

| G | 16 |

| H | 17 |

| J | 18 |

| K | 19 |

The second letter represents the multiplier, as shown in this table:

| Letter | Multiplier |

|---|---|

| A | 1 |

| B | 10 |

| C | 100 |

| D | 1,000 |

| E | 10,000 |

| F | 100,000 |

| G | 1,000,000 |

| H | 0.01 |

| J | 0.1 |

| K | 0.001 |

To calculate the capacitance value, combine the first and second significant digits and multiply the result by the multiplier.

For example, if a capacitor is marked with “JB”, the capacitance value would be:

First letter “J” = 18

Second letter “B” = Multiplier of 10

Capacitance = 18 × 10 = 180 pF

Tolerance Code

The tolerance code is represented by a single number following the capacitance code. Here’s the table for tolerance codes:

| Number | Tolerance |

|---|---|

| 1 | ±1% |

| 2 | ±2% |

| 5 | ±5% |

| 8 | ±0.5% |

| 9 | ±10% |

| 0 | ±20% |

For example, if a capacitor is marked with “JB5”, it has a capacitance of 180 pF with a tolerance of ±5%.

Metric Coding System

The metric coding system, also known as the “European” coding system, uses a combination of numbers and letters to indicate the capacitance and tolerance of SMD capacitors. This system is commonly used for film and aluminum electrolytic capacitors.

Capacitance Code

In the metric system, the capacitance value is represented by a three-digit code. The first two digits are the significant digits, while the third digit is the multiplier (number of zeros to be added after the significant digits).

For example, if a capacitor is marked with “474”, the capacitance value would be:

First two digits = 47

Third digit (multiplier) = 4, meaning add four zeros after 47

Capacitance = 470,000 pF or 0.47 µF

Tolerance Code

The tolerance code in the metric system is represented by a letter following the capacitance code. Here’s the table for tolerance codes:

| Letter | Tolerance |

|---|---|

| F | ±1% |

| G | ±2% |

| H | ±3% |

| J | ±5% |

| K | ±10% |

| M | ±20% |

For example, if a capacitor is marked with “474J”, it has a capacitance of 0.47 µF with a tolerance of ±5%.

Manufacturer-Specific Coding Systems

Some capacitor manufacturers use their own proprietary coding systems, which may differ from the industry standards. In these cases, it’s crucial to consult the manufacturer’s documentation or datasheet to accurately decode the capacitor’s specifications.

Examples of manufacturers with proprietary coding systems include:

-

Murata: Murata uses a coding system similar to the EIA-96 standard but with some variations in the tolerance codes.

-

TDK: TDK employs a coding system that combines elements of the EIA-96 and metric systems, along with some unique codes for specific capacitor types.

-

Kemet: Kemet uses a coding system that closely resembles the EIA-96 standard but with additional codes for special features and packaging options.

When working with capacitors from these or other manufacturers, always refer to their documentation to ensure accurate interpretation of the codes.

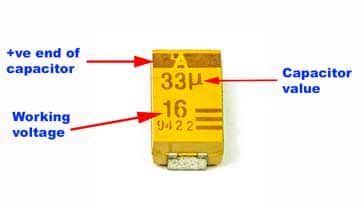

Voltage Rating and Other Markings

In addition to the capacitance and tolerance codes, SMD capacitors may also be marked with their voltage rating and other information. The voltage rating indicates the maximum voltage that the capacitor can withstand without damage or degradation of performance.

Voltage ratings are typically printed on the capacitor in one of two ways:

-

Directly: The voltage rating may be printed directly on the capacitor, usually in volts (V). For example, “50V” would indicate a voltage rating of 50 volts.

-

Code: Some manufacturers use a code to represent the voltage rating. For example, “1C” might indicate a voltage rating of 16 volts, while “1E” could represent 25 volts. These codes vary among manufacturers, so it’s essential to consult the appropriate documentation.

Other markings that may appear on SMD capacitors include:

- Series or product code: Indicates the manufacturer’s series or product line.

- Date code: Represents the date of manufacture, often in a format such as YYWW (year and week).

- Polarity: For polarized capacitors (e.g., tantalum and aluminum electrolytic), a polarity marking (“+”) indicates the positive terminal.

Frequently Asked Questions (FAQ)

-

What does “SMD” stand for in SMD capacitor?

SMD stands for “Surface-Mount Device”. SMD capacitors are designed to be soldered directly onto the surface of a printed circuit board (PCB), as opposed to through-hole capacitors that have leads that are inserted into holes in the PCB. -

How do I determine the voltage rating of an SMD capacitor?

The voltage rating of an SMD capacitor may be printed directly on the component in volts (V) or represented by a code. Consult the manufacturer’s documentation or datasheet to determine the voltage rating if a code is used. -

What do the letters in the EIA-96 capacitance code represent?

In the EIA-96 coding system, the first letter represents the first and second significant digits of the capacitance value, while the second letter represents the multiplier. The letters range from A to K, with each letter corresponding to a specific digit or multiplier. -

How do I identify the positive terminal on a polarized SMD capacitor?

Polarized SMD capacitors, such as tantalum and aluminum electrolytic capacitors, often have a polarity marking (“+”) to indicate the positive terminal. Always refer to the manufacturer’s documentation or datasheet to confirm the polarity marking convention. -

Can I use a capacitor with a higher voltage rating than my circuit requires?

Yes, you can use a capacitor with a higher voltage rating than your circuit requires. However, using a capacitor with a voltage rating lower than the circuit’s maximum voltage can lead to capacitor failure and potentially damage other components in the circuit. Always choose a capacitor with a voltage rating equal to or higher than the maximum voltage in your circuit.

Conclusion

Understanding SMD capacitor codes is essential for anyone working with electronic components. By learning to read and interpret these codes, you can quickly identify the capacitance, tolerance, and voltage rating of a capacitor, making it easier to select the right component for your project, troubleshoot circuits, and manage your inventory.

In this guide, we covered the most common coding systems used for SMD capacitors, including the EIA-96 standard, metric coding, and manufacturer-specific codes. We also discussed voltage ratings and other markings that may appear on these components.

Remember, while the coding systems presented here are widely used, some manufacturers may employ proprietary codes that deviate from these standards. Always consult the manufacturer’s documentation or datasheet to ensure accurate interpretation of the codes and to obtain any additional information specific to their products.

By mastering SMD capacitor codes, you’ll be well-equipped to tackle a wide range of electronic projects and troubleshooting tasks with confidence.

No responses yet