What is a Design BOM?

A Design Bill of Materials (BOM) is a comprehensive list of all the components, parts, and materials required to manufacture a product. It serves as a crucial document for product development, procurement, and production processes. The Design BOM is typically created during the design phase of a product and includes detailed information about each component, such as part numbers, descriptions, quantities, and specifications.

Importance of a Design BOM

The Design BOM plays a vital role in various aspects of product development and manufacturing:

-

Product Development: It helps designers and engineers keep track of all the components needed to create a product, ensuring that nothing is overlooked during the design process.

-

Procurement: The Design BOM serves as a reference for the procurement team to source the required components and materials from suppliers.

-

Production Planning: Manufacturing teams use the Design BOM to plan and schedule production activities, ensuring that all necessary components are available when needed.

-

Cost Estimation: By providing a detailed list of components and their quantities, the Design BOM helps in estimating the overall cost of the product.

Creating a Design BOM in Excel Format

Excel is a popular choice for creating and managing Design BOMs due to its simplicity, flexibility, and widespread availability. Here’s a step-by-step guide on how to create a Design BOM in Excel format:

Step 1: Determine the BOM Structure

Before creating your Design BOM, decide on the structure and hierarchy of your product. This involves breaking down the product into its main assemblies, sub-assemblies, and individual components. Consider the following aspects:

- Product hierarchy: Identify the top-level assemblies and how they are broken down into sub-assemblies and components.

- Component categories: Group similar components together, such as electrical parts, mechanical parts, or fasteners.

Step 2: Set Up the Excel Sheet

Open a new Excel workbook and set up the sheet to accommodate your Design BOM:

- Column Headers: Create column headers for the essential information you want to include in your BOM. Common headers include:

- Part Number

- Description

- Quantity

- Unit of Measure

- Material

- Supplier

- Cost

-

Lead Time

-

Formatting: Apply appropriate formatting to the headers and columns to make the BOM easily readable and visually appealing.

Step 3: Enter BOM Data

Start entering the data for each component in your Design BOM:

-

Part Number: Assign a unique part number to each component. This can be an internal numbering system or one provided by your suppliers.

-

Description: Provide a clear and concise description of each component, including any relevant specifications or characteristics.

-

Quantity: Specify the number of each component required to manufacture one unit of your product.

-

Unit of Measure: Indicate the unit of measure for each component, such as pieces, meters, or kilograms.

-

Material: If applicable, specify the material of each component.

-

Supplier: Include the name of the supplier for each component, along with their contact information.

-

Cost: Enter the cost per unit for each component.

-

Lead Time: Specify the lead time required to procure each component from the supplier.

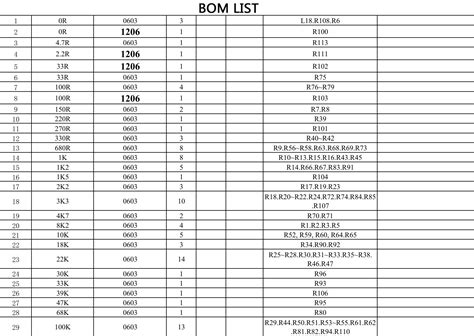

Here’s an example of how your Design BOM might look in Excel format:

| Part Number | Description | Quantity | Unit of Measure | Material | Supplier | Cost | Lead Time |

|---|---|---|---|---|---|---|---|

| E001 | 10K Ohm Resistor | 4 | Pcs | Carbon | ABC Inc. | 0.05 | 2 weeks |

| M002 | M3x10 Screw | 12 | Pcs | Stainless | XYZ Co. | 0.10 | 1 week |

| P003 | PCB Board | 1 | Pcs | FR4 | PCB Ltd. | 5.00 | 3 weeks |

Step 4: Validate and Review

Once you have entered all the data for your Design BOM, it’s essential to validate and review the information:

-

Accuracy: Double-check the part numbers, descriptions, quantities, and other details to ensure accuracy.

-

Completeness: Make sure that all necessary components are included in the BOM and that no parts are missing.

-

Consistency: Verify that the data is consistent across the BOM, such as using the same unit of measure for similar components.

-

Formatting: Check the formatting of the Excel sheet to ensure that it is clean, organized, and easy to read.

Step 5: Collaborate and Update

A Design BOM is often a collaborative effort involving multiple teams and stakeholders. It’s important to establish a process for sharing, reviewing, and updating the BOM:

-

Sharing: Determine how the Design BOM will be shared among team members, such as through a shared network drive or a cloud-based platform like Google Sheets or Microsoft OneDrive.

-

Access Control: Set up appropriate access controls to ensure that only authorized individuals can view or modify the BOM.

-

Version Control: Implement a version control system to track changes made to the BOM over time. This can be as simple as adding a version number or date to the file name.

-

Change Management: Establish a process for managing changes to the Design BOM, including how change requests are submitted, reviewed, and approved.

Benefits of Using Excel for Design BOM

Using Excel to create and manage your Design BOM offers several advantages:

-

Familiarity: Excel is a widely used software, and most people are familiar with its basic functions, making it easy for team members to work with the BOM.

-

Flexibility: Excel allows you to customize the BOM structure, add or remove columns, and apply formatting to suit your specific needs.

-

Calculations: With Excel’s built-in formulas and functions, you can perform calculations directly within the BOM, such as totaling quantities or calculating costs.

-

Sorting and Filtering: Excel’s sorting and filtering capabilities make it easy to organize and analyze BOM data based on different criteria.

-

Integration: Excel files can be easily imported into other software systems, such as ERP or PLM, for further processing and management.

Best Practices for Managing Design BOM in Excel

To ensure the effectiveness and integrity of your Design BOM in Excel, consider the following best practices:

-

Standardization: Establish standardized naming conventions, part numbering systems, and data formats to maintain consistency across the BOM.

-

Data Validation: Use Excel’s data validation features to restrict the input of invalid or inconsistent data in the BOM.

-

Backup and Security: Regularly backup your Design BOM and store it in a secure location to prevent data loss or unauthorized access.

-

Training: Provide training to team members on how to use and maintain the Design BOM in Excel format.

-

Continuous Improvement: Regularly review and update the Design BOM based on feedback from team members and lessons learned during the product development process.

Frequently Asked Questions (FAQ)

-

What is the difference between a Design BOM and a Manufacturing BOM?

A Design BOM focuses on the components and materials required to design a product, while a Manufacturing BOM includes additional information needed for production, such as assembly instructions and packaging requirements. -

Can a Design BOM be used for multiple products?

Yes, a Design BOM can be used as a template for similar products with minor variations. However, it’s important to create separate BOMs for products with significant differences in components or structure. -

How often should a Design BOM be updated?

A Design BOM should be updated whenever there are changes to the product design, components, or suppliers. It’s important to maintain an up-to-date BOM to ensure accurate information for procurement and production. -

Can a Design BOM be integrated with other software systems?

Yes, a Design BOM created in Excel format can be easily imported into other software systems, such as ERP, PLM, or CAD, for further processing and management. -

Who is responsible for creating and maintaining the Design BOM?

The responsibility for creating and maintaining the Design BOM typically lies with the design or engineering team. However, it’s important to involve other stakeholders, such as procurement and manufacturing, to ensure the BOM meets their requirements.

Conclusion

A well-structured and maintained Design BOM is essential for the success of any product development project. By using Excel to create and manage your Design BOM, you can ensure that all the necessary information is captured, organized, and easily accessible to all stakeholders. By following best practices and continuously improving your BOM management processes, you can streamline your product development efforts and bring your products to market more efficiently.

No responses yet