Introduction to Extruded 3D Bodies

Extruded 3D bodies are three-dimensional geometric shapes formed by taking a 2D shape and extending it along a straight line to create depth and volume. This process of extrusion is commonly used in computer-aided design (CAD) software and 3D modeling applications to create various 3D objects. Extruded bodies can be based on simple shapes like circles, rectangles, or more complex profiles.

In this article, we will focus on extruded spherical cylindrical bodies – 3D shapes created by extruding circular or spherical cross-sections. These shapes have wide-ranging applications in engineering, product design, architecture, and art.

Types of Extruded Spherical Cylindrical Bodies

There are several types of extruded spherical cylindrical bodies, including:

- Cylinders

- Spheres

- Cones

- Ellipsoids

- Paraboloids

- Hyperboloids

Each of these shapes has unique geometric properties and can be created through different extrusion methods.

Cylinders

A cylinder is a 3D body formed by extruding a circle along a straight line perpendicular to its plane. It has two circular bases connected by a curved surface. The height of the cylinder is the distance between the two bases.

Properties of Cylinders

- Cylinders have a constant circular cross-section along their length.

- The volume of a cylinder is given by the formula: V = πr²h, where r is the radius of the base and h is the height.

- The surface area of a cylinder is given by the formula: A = 2πrh + 2πr², which includes the area of the curved surface and the two circular bases.

Applications of Cylinders

Cylinders are used in various fields, such as:

- Mechanical engineering: pistons, pipes, rollers

- Architecture: columns, pillars, towers

- Product design: cans, bottles, containers

Spheres

A sphere is a 3D body formed by extruding a circle around a central point, creating a perfectly round object. It is defined as the set of all points in space that are equidistant from a given point, called the center.

Properties of Spheres

- Spheres have a constant curvature and a uniform surface.

- The volume of a sphere is given by the formula: V = (4/3)πr³, where r is the radius.

- The surface area of a sphere is given by the formula: A = 4πr².

Applications of Spheres

Spheres are used in various fields, such as:

- Sports: balls for soccer, basketball, tennis, etc.

- Astronomy: celestial bodies like planets, moons, and stars

- Physics: modeling particles, atoms, and molecules

Cones

A cone is a 3D body formed by extruding a circle along a straight line that intersects the plane of the circle at an angle. It has a circular base and a single vertex point.

Properties of Cones

- Cones have a circular base and a tapering curved surface that ends at a single point called the apex or vertex.

- The volume of a cone is given by the formula: V = (1/3)πr²h, where r is the radius of the base and h is the height.

- The surface area of a cone is given by the formula: A = πrs + πr², where s is the slant height (the distance from the apex to any point on the circular base).

Applications of Cones

Cones are used in various fields, such as:

- Traffic control: traffic cones, pylons

- Food industry: ice cream cones, funnel cakes

- Aerospace: nose cones of rockets and missiles

Ellipsoids

An ellipsoid is a 3D body formed by extruding an ellipse around its center point. It is a symmetrical shape with three distinct axes: the major axis (longest), the minor axis (shortest), and the intermediate axis.

Properties of Ellipsoids

- Ellipsoids have a smooth, curved surface with no edges or vertices.

- The volume of an ellipsoid is given by the formula: V = (4/3)πabc, where a, b, and c are the lengths of the semi-axes.

- The surface area of an ellipsoid has no simple formula and is usually approximated using numerical methods.

Applications of Ellipsoids

Ellipsoids are used in various fields, such as:

- Geodesy: modeling the shape of the Earth and other celestial bodies

- Physics: studying the motion of particles in gravitational and electromagnetic fields

- Computer graphics: creating realistic 3D models and animations

Paraboloids

A paraboloid is a 3D body formed by extruding a parabola around its axis of symmetry. There are two types of paraboloids: elliptic and hyperbolic.

Properties of Paraboloids

- Elliptic paraboloids have a bowl-like shape with a single minimum point, while hyperbolic paraboloids have a saddle-like shape with a single maximum point.

- The volume and surface area of paraboloids have complex formulas that depend on the specific equation of the generating parabola.

Applications of Paraboloids

Paraboloids are used in various fields, such as:

- Optics: designing reflective surfaces for telescopes, headlights, and solar concentrators

- Architecture: creating unique roof structures and facades

- Electromagnetic theory: modeling the propagation of waves and signals

Hyperboloids

A hyperboloid is a 3D body formed by extruding a hyperbola around its axis of symmetry. There are two types of hyperboloids: one-sheet and two-sheet.

Properties of Hyperboloids

- One-sheet hyperboloids have a single continuous surface that extends infinitely in both directions, while two-sheet hyperboloids consist of two separate mirror-image surfaces.

- The volume and surface area of hyperboloids have complex formulas that depend on the specific equation of the generating hyperbola.

Applications of Hyperboloids

Hyperboloids are used in various fields, such as:

- Engineering: designing cooling towers, water tanks, and other structures

- Art: creating sculptural forms and installations

- Mathematics: studying quadric surfaces and their properties

Extrusion Methods

There are several methods for creating extruded spherical cylindrical bodies, including:

- Linear extrusion

- Rotational extrusion

- Swept extrusion

- Lofted extrusion

Linear Extrusion

Linear extrusion involves extending a 2D shape along a straight line to create a 3D body with a constant cross-section. This method is commonly used for creating cylinders, prisms, and other shapes with parallel sides.

Rotational Extrusion

Rotational extrusion, also known as revolve or spin, involves rotating a 2D shape around an axis to create a 3D body with a circular cross-section. This method is used for creating spheres, cones, and other shapes with rotational symmetry.

Swept Extrusion

Swept extrusion involves moving a 2D shape along a curved path to create a 3D body with a varying cross-section. This method is used for creating complex shapes like spirals, helices, and other curved forms.

Lofted Extrusion

Lofted extrusion involves connecting a series of 2D shapes along a path to create a 3D body with a smooth transition between cross-sections. This method is used for creating organic shapes, like boat hulls, airplane wings, and other streamlined forms.

Applications of Extruded Spherical Cylindrical Bodies

Extruded spherical cylindrical bodies have numerous applications across various industries, including:

- Aerospace engineering

- Automotive design

- Architecture and construction

- Product design and manufacturing

- Art and sculpture

Aerospace Engineering

In aerospace engineering, extruded spherical cylindrical bodies are used for designing:

- Fuselages and wings of aircraft

- Rocket bodies and nose cones

- Satellites and space stations

These shapes are chosen for their aerodynamic properties, structural strength, and efficiency in withstanding the forces encountered during flight.

Automotive Design

In automotive design, extruded spherical cylindrical bodies are used for creating:

- Car bodies and chassis

- Wheels and tires

- Exhaust pipes and mufflers

These shapes are selected for their aesthetic appeal, functional performance, and compatibility with manufacturing processes.

Architecture and Construction

In architecture and construction, extruded spherical cylindrical bodies are used for designing:

- Columns and pillars

- Domes and vaults

- Tunnels and bridges

These shapes are chosen for their structural stability, load-bearing capacity, and visual impact in building design.

Product Design and Manufacturing

In product design and manufacturing, extruded spherical cylindrical bodies are used for creating:

- Containers and packaging

- Furniture and appliances

- Medical devices and implants

These shapes are selected for their ergonomics, ease of manufacturing, and suitability for mass production.

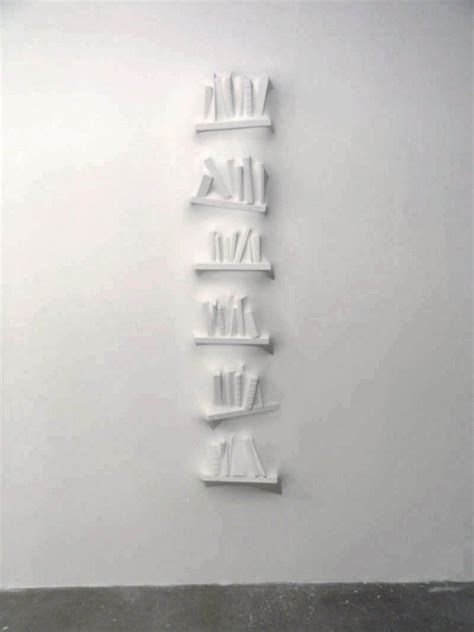

Art and Sculpture

In art and sculpture, extruded spherical cylindrical bodies are used for creating:

- Abstract and geometric forms

- Kinetic and interactive installations

- Large-scale public art and monuments

These shapes are chosen for their aesthetic qualities, symbolic meanings, and ability to engage viewers in a spatial experience.

Challenges and Limitations

While extruded spherical cylindrical bodies offer many advantages, there are also some challenges and limitations to consider:

- Complexity of design and modeling

- Difficulty of manufacturing and fabrication

- Material limitations and cost considerations

Complexity of Design and Modeling

Creating complex extruded spherical cylindrical bodies requires advanced CAD software and 3D modeling skills. Designers must have a deep understanding of geometry, topology, and surface modeling to create accurate and efficient models.

Difficulty of Manufacturing and Fabrication

Manufacturing extruded spherical cylindrical bodies can be challenging, especially for complex shapes with varying cross-sections and curved surfaces. Specialized equipment and skilled labor may be required, leading to higher production costs and longer lead times.

Material Limitations and Cost Considerations

The choice of materials for extruded spherical cylindrical bodies depends on the specific application and performance requirements. Some materials may not be suitable for certain shapes or sizes due to their physical properties or cost. Designers must carefully consider the trade-offs between performance, aesthetics, and affordability when selecting materials.

Future Developments and Trends

As technology advances, new developments and trends are emerging in the field of extruded spherical cylindrical bodies:

- Generative design and optimization

- Additive manufacturing and 3D printing

- Smart materials and responsive structures

Generative Design and Optimization

Generative design uses artificial intelligence and machine learning algorithms to explore a vast range of design options and optimize for specific criteria, such as weight, strength, or performance. This approach can lead to novel and efficient extruded spherical cylindrical bodies that would be difficult to conceive using traditional design methods.

Additive Manufacturing and 3D Printing

Additive manufacturing, also known as 3D printing, enables the creation of complex extruded spherical cylindrical bodies directly from digital models, without the need for molds or tooling. This technology offers greater design freedom, faster prototyping, and more efficient production of customized parts.

Smart Materials and Responsive Structures

Smart materials, such as shape memory alloys and piezoelectric polymers, can change their shape or properties in response to external stimuli, like heat, light, or electric fields. These materials can be used to create extruded spherical cylindrical bodies that adapt to their environment, perform specific functions, or interact with users in novel ways.

Frequently Asked Questions (FAQ)

1. What is the difference between linear and rotational extrusion?

Linear extrusion involves extending a 2D shape along a straight line to create a 3D body with a constant cross-section, while rotational extrusion involves rotating a 2D shape around an axis to create a 3D body with a circular cross-section.

2. Can extruded spherical cylindrical bodies be hollow?

Yes, extruded spherical cylindrical bodies can be designed as hollow structures by specifying a wall thickness during the extrusion process. Hollow bodies are often used to reduce weight, save material, or create space for internal components.

3. What are the advantages of using generative design for extruded spherical cylindrical bodies?

Generative design can explore a vast range of design options and optimize for specific criteria, leading to novel and efficient extruded spherical cylindrical bodies that would be difficult to conceive using traditional design methods. This approach can save time, reduce material usage, and improve performance.

4. How does additive manufacturing benefit the production of extruded spherical cylindrical bodies?

Additive manufacturing, or 3D printing, enables the creation of complex extruded spherical cylindrical bodies directly from digital models, without the need for molds or tooling. This technology offers greater design freedom, faster prototyping, and more efficient production of customized parts, reducing lead times and costs.

5. What are smart materials, and how can they be used in extruded spherical cylindrical bodies?

Smart materials are materials that can change their shape or properties in response to external stimuli, like heat, light, or electric fields. They can be used to create extruded spherical cylindrical bodies that adapt to their environment, perform specific functions, or interact with users in novel ways, enabling new applications and experiences.

Conclusion

Extruded spherical cylindrical bodies are versatile and widely used 3D shapes that have numerous applications across various industries, from aerospace and automotive engineering to architecture, product design, and art. By understanding the properties, methods, and challenges of creating these shapes, designers and engineers can unlock new possibilities for innovation and creativity.

As technology continues to advance, new developments and trends, such as generative design, additive manufacturing, and smart materials, are transforming the way extruded spherical cylindrical bodies are conceived, produced, and used. By staying informed and adapting to these changes, professionals can stay ahead of the curve and create more efficient, sustainable, and innovative solutions for a wide range of applications.

No responses yet