Introduction to 3D Circuit Design

Traditional electronic circuits are designed and manufactured in a planar, two-dimensional (2D) layout on printed circuit boards (PCBs). While this approach has been the standard for decades, it has limitations in terms of circuit density, performance, and form factor. As electronic devices become more complex and compact, there is a growing need for a paradigm shift in circuit design. Enter true three-dimensional (3D) circuit design, a revolutionary approach that enables the creation of highly integrated, high-performance electronic systems in compact, flexible, and unconventional form factors.

What is True 3D Circuit Design?

True 3D circuit design involves the arrangement of electronic components and interconnects in a three-dimensional space, unlike traditional 2D circuits that are confined to a single plane. In a true 3D circuit, components can be stacked vertically, and interconnects can follow complex 3D paths, allowing for higher component density, shorter signal paths, and more efficient use of space. This approach opens up new possibilities for electronic device design, enabling the creation of compact, high-performance systems with unique form factors.

Benefits of 3D Circuit Design

- Increased circuit density

- Improved signal integrity and reduced signal delay

- Enhanced thermal management

- Reduced form factor and weight

- Greater design flexibility and freedom

- Potential for new applications and device concepts

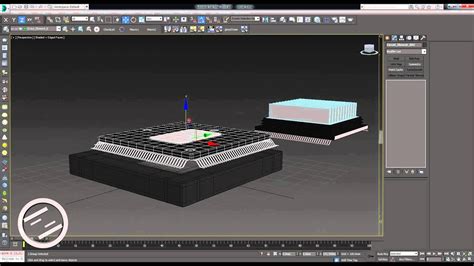

Circuit3D: A Breakthrough in 3D Circuit Design Software

To fully harness the potential of true 3D circuit design, engineers and designers need powerful, intuitive software tools that can handle the complexity of 3D layouts. Circuit3D is a groundbreaking software solution that enables the design, simulation, and optimization of true 3D electronic circuits. Developed by a team of experts in electronic design automation (EDA) and 3D modeling, Circuit3D provides a comprehensive suite of tools for creating cutting-edge 3D circuits.

Key Features of Circuit3D

-

3D component library: Circuit3D includes a vast library of 3D models for electronic components, allowing designers to easily place and orient components in a 3D space.

-

Intelligent 3D routing: The software features advanced algorithms for automatic 3D routing of interconnects, optimizing signal paths and minimizing crosstalk.

-

3D circuit simulation: Circuit3D integrates with leading circuit simulation tools, enabling accurate simulation and analysis of 3D circuits.

-

Thermal analysis: The software includes tools for thermal modeling and analysis, helping designers optimize thermal management in 3D circuits.

-

Design rule checking (DRC): Circuit3D automatically checks 3D layouts for compliance with design rules, ensuring manufacturability and reliability.

-

Export to 3D printing and manufacturing: The software supports export to various 3D printing formats and generates manufacturing-ready files for 3D circuit fabrication.

Circuit3D Workflow

The typical workflow in Circuit3D involves the following steps:

- Create a new 3D circuit project

- Import or create 3D models of electronic components

- Place and orient components in the 3D workspace

- Define electrical connections and constraints

- Perform automatic or manual 3D routing of interconnects

- Simulate and analyze the 3D circuit

- Optimize the design based on simulation results

- Perform design rule checks

- Export the final design for 3D printing or manufacturing

Applications of True 3D Circuit Design

True 3D circuit design, enabled by powerful software tools like Circuit3D, has the potential to revolutionize various industries and application areas. Some of the most promising applications include:

Wearable Electronics

3D circuits can be designed to conform to the human body, enabling the creation of comfortable, unobtrusive wearable devices for health monitoring, fitness tracking, and personal communication.

Implantable Medical Devices

Compact, biocompatible 3D circuits can be used to create advanced implantable medical devices, such as pacemakers, neurostimulators, and drug delivery systems.

Aerospace and Defense

3D circuits can help reduce the size and weight of electronic systems in aircraft, satellites, and military equipment, while improving performance and reliability.

Internet of Things (IoT) Devices

True 3D circuit design can enable the development of compact, low-power IoT devices for smart homes, industrial automation, and environmental monitoring.

Robotics and Automation

3D circuits can be integrated into robotic systems, enabling more compact, flexible, and intelligent robots for various applications, such as manufacturing, healthcare, and exploration.

Challenges and Future Directions

While true 3D circuit design offers numerous benefits, it also presents several challenges that need to be addressed for widespread adoption:

Manufacturing and Assembly

3D circuits require advanced manufacturing techniques, such as 3D printing, laser direct structuring (LDS), and embedded component packaging. Further advancements in these technologies are needed to improve the precision, reliability, and cost-effectiveness of 3D circuit fabrication.

Standardization and Design Rules

Industry-wide standards and design rules need to be established to ensure interoperability and manufacturability of 3D circuits across different tools and fabrication processes.

Thermal Management

As circuit density increases in 3D layouts, thermal management becomes more challenging. Advanced cooling solutions, such as 3D-printed heatsinks and microfluidic cooling, need to be developed and integrated into 3D circuit design tools.

Simulation and Verification

Simulating and verifying the performance of 3D circuits is more complex than traditional 2D circuits. Advances in 3D circuit simulation algorithms and tools are needed to accurately predict and optimize the behavior of 3D circuits.

Despite these challenges, the future of true 3D circuit design is bright. As software tools like Circuit3D continue to evolve and mature, and manufacturing technologies advance, we can expect to see more widespread adoption of 3D circuits in various industries. This will lead to a new generation of electronic devices that are smaller, faster, and more capable than ever before.

Frequently Asked Questions (FAQ)

1. What is the difference between 3D IC packaging and true 3D circuit design?

3D IC packaging involves stacking multiple 2D circuit layers vertically and connecting them using through-silicon vias (TSVs). While this approach increases circuit density, it still relies on planar 2D circuits within each layer. True 3D circuit design, on the other hand, involves arranging components and interconnects in a fully three-dimensional space, enabling more complex and compact layouts.

2. Can existing 2D circuit designs be converted to 3D using Circuit3D?

Yes, Circuit3D includes tools for importing existing 2D circuit layouts and converting them into 3D designs. However, to fully benefit from the advantages of true 3D circuit design, it is recommended to design circuits from the ground up in a 3D environment.

3. What 3D printing technologies are compatible with Circuit3D?

Circuit3D supports various 3D printing technologies, including fused deposition modeling (FDM), stereolithography (SLA), and selective laser sintering (SLS). The software can export 3D circuit designs in common 3D printing file formats, such as STL and OBJ.

4. How does Circuit3D handle the simulation of 3D circuits?

Circuit3D integrates with leading circuit simulation tools, such as SPICE and ANSYS, to perform accurate simulations of 3D circuits. The software automatically generates the necessary simulation models and netlists based on the 3D circuit layout, taking into account the 3D geometry and material properties.

5. What is the learning curve for using Circuit3D?

While Circuit3D is designed to be intuitive and user-friendly, users should have a basic understanding of electronic circuit design and 3D modeling concepts. The software includes comprehensive documentation, tutorials, and example projects to help users get started. For complex 3D circuit designs, it is recommended to have a team with expertise in both electronic design and 3D modeling.

Conclusion

True 3D circuit design, powered by innovative software tools like Circuit3D, represents a major leap forward in electronic design. By enabling the creation of highly integrated, high-performance electronic systems in compact, flexible, and unconventional form factors, 3D circuits have the potential to transform various industries and application areas. As the technology continues to advance and mature, we can expect to see more widespread adoption of true 3D circuit design, leading to a new era of electronic devices that push the boundaries of what is possible.

| Aspect | Traditional 2D Circuits | True 3D Circuits |

|---|---|---|

| Component placement | Planar, single layer | 3D space, multiple layers |

| Interconnect routing | 2D traces | 3D paths |

| Circuit density | Limited by 2D layout | High, enables compact designs |

| Signal integrity | Affected by long 2D traces | Improved, shorter 3D paths |

| Thermal management | Planar heatsinks, limited options | 3D heatsinks, advanced cooling solutions |

| Form factor | Planar, rigid PCBs | Flexible, conformal, unconventional shapes |

| Design tools | Mature 2D EDA software | Emerging 3D design tools like Circuit3D |

No responses yet