In the ever-evolving world of electronics manufacturing, printed circuit board (PCB) assembly services play a crucial role in bringing innovative designs to life. From consumer electronics to industrial automation systems, PCBs are the backbone of countless electronic devices, enabling complex functionalities and interconnections. This article delves into the realm of PCB assembly services, exploring their importance, processes, and best practices.

What are PCB Assembly Services?

PCB assembly services refer to the specialized processes and capabilities offered by contract manufacturers or electronics manufacturing services (EMS) providers to assemble and integrate electronic components onto printed circuit boards. These services encompass a range of activities, including component sourcing, PCB fabrication, surface mount technology (SMT) assembly, through-hole assembly, testing, and quality assurance.

By outsourcing PCB assembly services, original equipment manufacturers (OEMs) and product developers can focus their resources on core competencies, such as design and innovation, while leveraging the expertise and scalability of specialized assembly partners.

The Importance of PCB Assembly Services

PCB assembly services play a critical role in the electronics manufacturing industry, offering numerous benefits to OEMs and product developers:

- Expertise and Specialized Knowledge: PCB assembly service providers possess extensive knowledge and experience in handling complex assembly processes, ensuring high-quality and reliable products.

- Access to Advanced Manufacturing Technologies: These service providers invest in state-of-the-art equipment and technologies, enabling them to handle intricate designs and meet stringent manufacturing requirements.

- Scalability and Flexibility: PCB assembly services offer scalable production capabilities, allowing OEMs to adjust volumes based on market demand without significant capital investments.

- Cost Optimization: By leveraging economies of scale and streamlined processes, PCB assembly service providers can often offer cost-effective solutions, reducing overall manufacturing expenses.

- Reduced Time-to-Market: With dedicated assembly lines and efficient processes, PCB assembly services can help OEMs and product developers bring their products to market faster, gaining a competitive edge.

- Regulatory Compliance: Reputable PCB assembly service providers stay up-to-date with industry regulations and standards, ensuring compliance with necessary certifications and quality requirements.

The PCB Assembly Process

The PCB assembly process involves several critical steps to transform design files into functional electronic devices. While specific procedures may vary among service providers, the general process typically follows these stages:

1. Component Sourcing and Procurement

Before assembly can begin, the necessary electronic components must be sourced from reliable suppliers. PCB assembly service providers often have established supply chain networks and purchasing power to secure high-quality components at competitive prices.

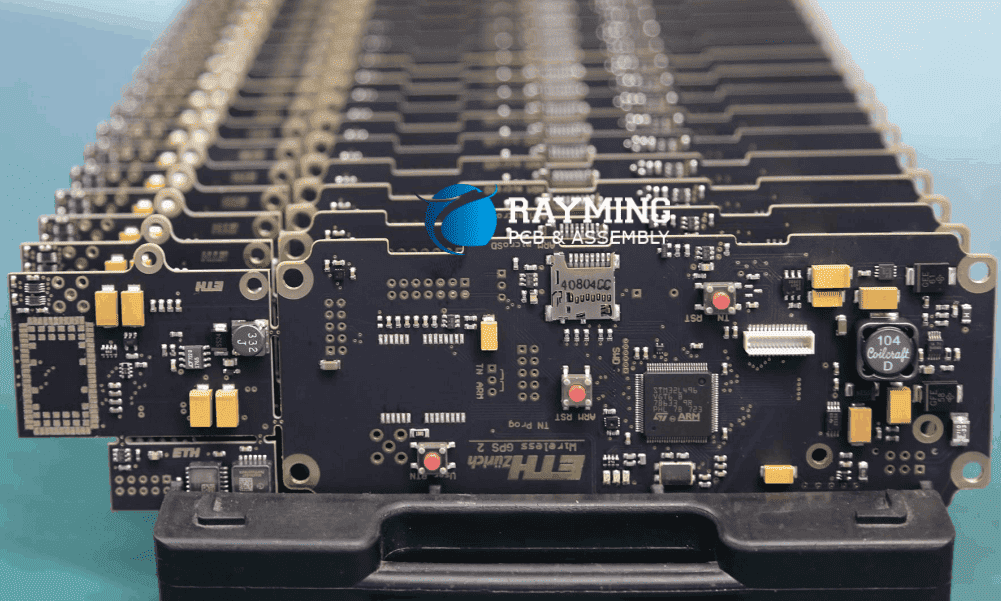

2. PCB Fabrication

The PCB fabrication process involves creating the physical circuit board by etching conductive patterns onto a non-conductive substrate. This stage may be outsourced to specialized PCB fabrication facilities or performed in-house by some assembly service providers.

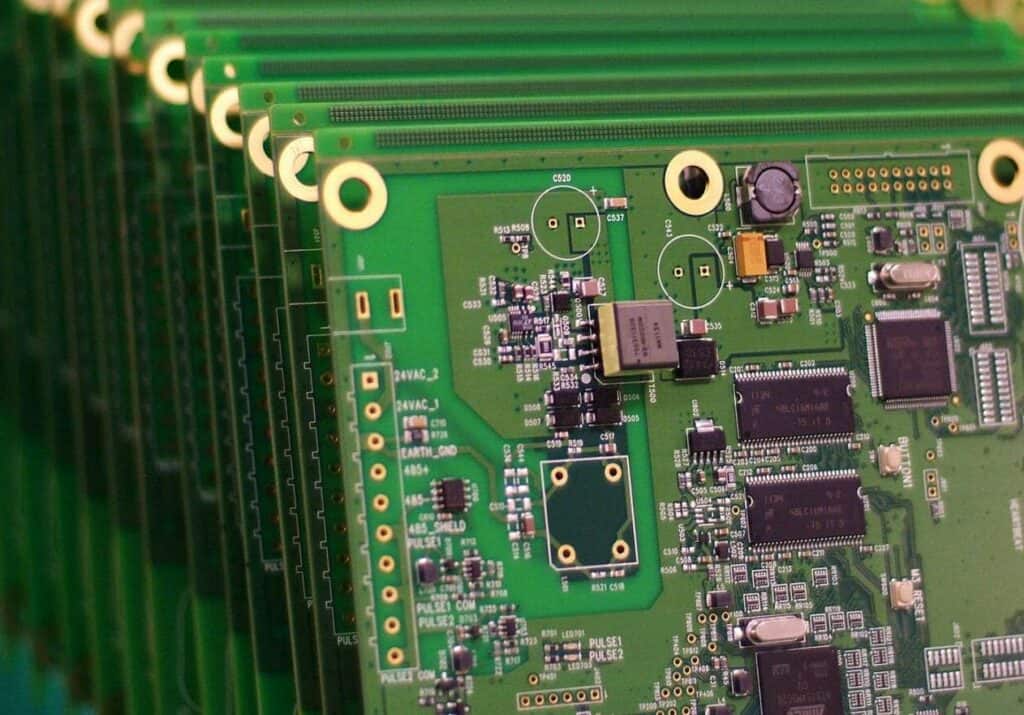

3. Surface Mount Technology (SMT) Assembly

Surface mount technology (SMT) assembly is a widely adopted process for assembling miniaturized electronic components directly onto the surface of the PCB. Automated SMT assembly lines use precision pick-and-place machines to accurately place components onto the circuit board.

4. Through-Hole Assembly

For components with lead wires, such as connectors or transformers, through-hole assembly is required. This process involves inserting the component leads into pre-drilled holes on the PCB and soldering them in place, often using wave soldering or selective soldering techniques.

5. Inspection and Testing

Quality control is a critical aspect of PCB assembly services. Automated optical inspection (AOI) systems and functional testing procedures are employed to identify and rectify any defects or issues before final assembly.

6. Conformal Coating (optional)

Depending on the application and environmental requirements, PCB assembly service providers may offer conformal coating services. This process involves applying a protective layer over the assembled PCB to shield it from moisture, dust, and other contaminants.

7. Final Assembly and Packaging

The final assembly stage involves integrating the assembled PCB into the product enclosure or housing, making necessary interconnections, and preparing the product for shipping and distribution.

Types of PCB Assembly Services

PCB assembly services can be broadly categorized into two main types:

1. Turnkey PCB Assembly Services

Turnkey PCB assembly services offer a comprehensive, end-to-end solution, encompassing all aspects of the assembly process, from component sourcing to final product delivery. These services are ideal for OEMs and product developers seeking a streamlined and hassle-free manufacturing experience.

2. Consignment PCB Assembly Services

In consignment PCB assembly services, the OEM or product developer provides the necessary components and PCBs, while the assembly service provider focuses on the assembly, testing, and quality assurance processes. This approach can be advantageous for companies with established supply chains or specific component requirements.

Selecting the Right PCB Assembly Service Provider

Choosing the right PCB assembly service provider is crucial for ensuring successful product development and manufacturing. Here are some key factors to consider:

- Capabilities and Expertise: Evaluate the service provider’s capabilities in terms of assembly technologies, component handling, and product complexity. Ensure they have experience working with designs similar to yours.

- Quality Management Systems: Look for service providers with robust quality management systems, certifications (e.g., ISO 9001, ISO 13485), and rigorous inspection and testing procedures.

- Supply Chain Management: Assess the service provider’s ability to source components efficiently, manage inventory, and mitigate supply chain risks.

- Scalability and Flexibility: Consider the service provider’s capacity to scale production volumes up or down based on your demand, as well as their ability to adapt to design changes or modifications.

- Communication and Collaboration: Effective communication and collaboration between the OEM and the service provider are essential for successful project execution. Evaluate their responsiveness, project management processes, and willingness to collaborate.

- Intellectual Property Protection: Ensure that the service provider has robust measures in place to protect your intellectual property, including non-disclosure agreements and data security protocols.

- Certifications and Compliance: Verify that the service provider adheres to relevant industry standards, regulations, and certifications specific to your product or market.

- Pricing and Cost Structure: Evaluate the service provider’s pricing and cost structure, considering factors such as component pricing, labor costs, and any additional services or fees.

Best Practices for Effective PCB Assembly Service Utilization

To maximize the benefits of PCB assembly services and ensure successful product development and manufacturing, consider the following best practices:

- Clear Communication of Requirements: Provide detailed specifications, design files, and requirements to the service provider, ensuring a shared understanding of the project goals and expectations.

- Collaborative Design Reviews: Engage in collaborative design reviews with the service provider to identify potential manufacturing challenges and opportunities for design optimization.

- Prototype Iteration: Leverage the service provider’s prototyping capabilities to iterate and refine your designs before committing to full-scale production.

- Supply Chain Management: Collaborate with the service provider to manage component sourcing, inventory levels, and supply chain risks, ensuring a smooth and uninterrupted assembly process.

- Quality Monitoring and Control: Establish clear quality control procedures and metrics, and regularly monitor the service provider’s performance to ensure consistent quality and adherence to specifications.

- Intellectual Property Protection: Implement robust measures to protect your intellectual property, including non-disclosure agreements, data encryption, and access controls.

- Continuous Improvement: Encourage a culture of continuous improvement by regularly reviewing processes, identifying opportunities for optimization, and incorporating feedback from the service provider and end-users.

- Contingency Planning: Develop contingency plans and risk mitigation strategies to address potential disruptions, such as supply chain issues, natural disasters, or changes in market demand.

FAQs

- Q: What is the difference between turnkey and consignment PCB assembly services? A: Turnkey PCB assembly services provide a comprehensive, end-to-end solution, including component sourcing, assembly, testing, and final delivery. Consignment services, on the other hand, involve the OEM or product developer providing the components and PCBs, while the service provider handles the assembly and testing processes.

- Q: How do PCB assembly service providers ensure quality and reliability? A: Reputable PCB assembly service providers implement robust quality management systems, automated inspection processes, functional testing, and adherence to industry standards and certifications. They also employ stringent process controls, training programs, and continuous improvement initiatives to maintain high levels of quality and reliability.

- Q: Can PCB assembly service providers handle complex or high-mix, low-volume production runs? A: Yes, many PCB assembly service providers have the capabilities and expertise to handle complex designs and high-mix, low-volume production runs. They often employ flexible manufacturing processes, advanced equipment, and skilled technicians to accommodate diverse product requirements.

- Q: How do PCB assembly service providers protect intellectual property? A: Intellectual property protection is a critical concern for OEMs and product developers. PCB assembly service providers implement measures such as non-disclosure agreements, data encryption, access controls, and secure facilities to safeguard proprietary information and designs.

- Q: What are the typical lead times for PCB assembly services? A: Lead times for PCB assembly services can vary depending on factors such as product complexity, component availability, production volumes, and the service provider’s capacity. However, many service providers offer expedited or quick-turn services to meet urgent delivery requirements.

Conclusion

PCB assembly services play a pivotal role in the electronics manufacturing industry, enabling OEMs and product developers to leverage specialized expertise, advanced technologies, and scalable production capabilities. By selecting the right PCB assembly service provider and implementing best practices, companies can streamline their manufacturing processes, reduce time-to-market, and deliver high-quality, reliable products to their customers.

As technology continues to evolve and product complexity increases, the demand for efficient and flexible PCB assembly services will only grow. By embracing these services and fostering collaborative partnerships, organizations can stay ahead of the curve, drive innovation, and meet the ever-changing demands of the electronics market.

No responses yet