What are Daughterboards?

A daughterboard, also known as a mezzanine board or piggyback board, is a printed circuit board (PCB) that connects to and extends the functionality of a main system board or motherboard. Daughterboards are widely used in electronic systems to add features, upgrade components, or customize hardware for specific applications. By connecting vertically to a motherboard via connectors or expansion slots, daughterboards provide a modular and space-efficient solution for expanding system capabilities.

Key Characteristics of Daughterboards

- Smaller than the main system board

- Connect vertically to the motherboard via connectors or slots

- Expand functionality without modifying the main board

- Modular and interchangeable for flexibility

- Specialized for specific purposes (e.g., sound cards, network cards, etc.)

Types of Daughterboards

Daughterboards come in various types, each designed for a specific purpose or function. Some common types of daughterboards include:

1. Expansion Cards

Expansion cards are daughterboards that plug into expansion slots on the motherboard to add features or capabilities. Examples include:

- Graphics cards (GPUs)

- Sound cards

- Network interface cards (NICs)

- TV tuner cards

- USB expansion cards

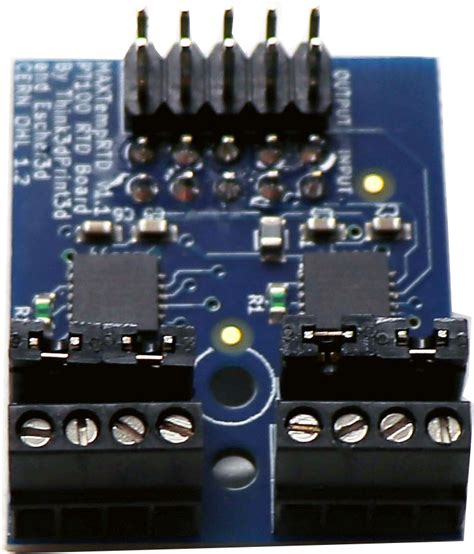

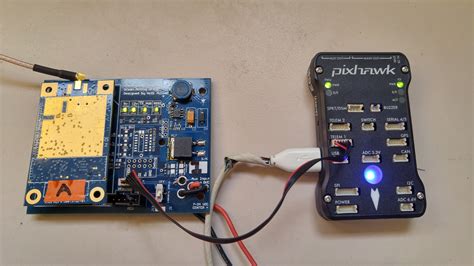

2. Mezzanine Cards

Mezzanine cards are daughterboards that connect to the motherboard using high-speed connectors, such as PCI Express (PCIe) or FMC (FPGA Mezzanine Card). They are commonly used in embedded systems, industrial applications, and high-performance computing. Examples include:

- FMC cards for FPGA-based systems

- PCIe cards for high-speed I/O or co-processing

- XMC (Switched Mezzanine Card) for ruggedized systems

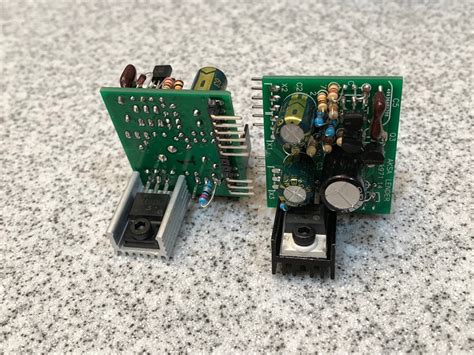

3. Function-specific Daughterboards

Some daughterboards are designed for specific functions or applications. These include:

- Sensor boards (e.g., GPS, accelerometer, gyroscope)

- Wireless communication boards (e.g., Wi-Fi, Bluetooth, cellular)

- Motor control boards

- Power management boards

- Display interface boards

Advantages of Using Daughterboards

Daughterboards offer several advantages over integrating all components directly onto the main system board:

-

Modularity and Flexibility: Daughterboards allow for easy customization and upgrades by swapping out boards with different features or capabilities. This modular approach enables systems to adapt to changing requirements without redesigning the entire motherboard.

-

Space Efficiency: Vertically connecting daughterboards to the motherboard saves space compared to placing all components on a single board. This is particularly beneficial in compact or high-density systems.

-

Cost Reduction: Designing and manufacturing separate daughterboards can be more cost-effective than integrating all components onto a single, complex motherboard. Daughterboards also allow for the reuse of common components across different system configurations.

-

Simplified Maintenance: Daughterboards make it easier to troubleshoot, repair, or replace specific components without disturbing the entire system. This can reduce downtime and maintenance costs.

-

Isolation and Signal Integrity: Separating sensitive or high-speed components onto daughterboards can improve signal integrity and reduce electromagnetic interference (EMI) by minimizing the distance between components and their associated circuits.

Designing with Daughterboards

When designing systems with daughterboards, several factors must be considered to ensure proper functionality, compatibility, and performance:

1. Connector Selection

Choosing the right connectors is crucial for reliable and efficient communication between the daughterboard and motherboard. Factors to consider include:

- Connector type (e.g., edge connector, mezzanine connector, board-to-board connector)

- Pitch and pin count

- Signal integrity and bandwidth requirements

- Mechanical stability and alignment

- Power delivery capacity

Some common connector types used for daughterboards include:

| Connector Type | Description | Applications |

|---|---|---|

| PCI Express (PCIe) | High-speed serial interface | Graphics cards, SSDs, expansion cards |

| FMC (FPGA Mezzanine Card) | High-pin-count, high-speed interface | FPGA-based systems, ADC/DAC boards |

| XMC (Switched Mezzanine Card) | Ruggedized, high-speed interface | Industrial, military, aerospace |

| Edge Connector | PCB edge with exposed copper fingers | Expansion cards, backplanes |

| Board-to-Board Connector | Vertical or right-angle connectors | Stacked PCBs, space-constrained systems |

2. Power Management

Ensuring proper power delivery to daughterboards is essential for reliable operation. Designers must consider:

- Power requirements of the daughterboard components

- Power supply capacity of the motherboard

- Power sequencing and control

- Voltage regulation and distribution on the daughterboard

3. Signal Integrity

Maintaining signal integrity is critical for high-speed communication between the daughterboard and motherboard. Designers should address:

- Impedance matching and termination

- Crosstalk and electromagnetic compatibility (EMC)

- Grounding and shielding

- PCB layout and routing techniques

4. Thermal Management

Daughterboards can generate significant heat, especially when housing high-performance components. Proper thermal management is necessary to ensure reliable operation and prevent overheating. Techniques include:

- Heatsinks and heat spreaders

- Thermal interface materials (TIMs)

- Airflow and ventilation

- Thermal monitoring and control

5. Mechanical Design

The mechanical design of daughterboards must consider factors such as:

- Board dimensions and form factor

- Mounting and retention mechanisms

- Vibration and shock resistance

- Component placement and clearances

Applications of Daughterboards

Daughterboards find applications across various industries and systems, including:

-

Personal Computers: Expansion cards, such as graphics cards and sound cards, are common daughterboards used in PCs to enhance performance and add features.

-

Embedded Systems: Daughterboards are widely used in embedded systems to add specialized functions, such as sensor interfaces, wireless communication, or motor control.

-

Industrial Automation: Industrial systems often use daughterboards for data acquisition, signal conditioning, or protocol conversion.

-

Telecommunications: Daughterboards are used in telecom equipment for functions like network interface, signal processing, or protocol handling.

-

Aerospace and Defense: Ruggedized daughterboards, such as XMC cards, are used in harsh environments for applications like radar processing, avionics, or satellite communication.

-

Medical Devices: Daughterboards are used in medical equipment for functions like sensor interfacing, data acquisition, or image processing.

-

Automotive Electronics: Daughterboards are increasingly used in automotive systems for applications like infotainment, advanced driver assistance systems (ADAS), or vehicle networking.

Frequently Asked Questions (FAQ)

1. What is the difference between a daughterboard and a motherboard?

A motherboard is the main printed circuit board in an electronic system that houses the central processing unit (CPU), memory, and other essential components. A daughterboard, on the other hand, is a smaller board that connects to the motherboard to extend its functionality or add specific features.

2. Can daughterboards be used in any system?

Daughterboards are designed to work with specific motherboards or systems that have compatible connectors or expansion slots. Not all systems support daughterboards, and compatibility must be ensured before using a daughterboard in a particular system.

3. How do I choose the right daughterboard for my application?

When selecting a daughterboard, consider factors such as the specific functions or features required, compatibility with the motherboard or system, performance requirements, power consumption, and environmental conditions (e.g., temperature, vibration, or humidity).

4. Can I design my own daughterboard?

Yes, custom daughterboards can be designed to meet specific application requirements. However, designing a daughterboard requires knowledge of electronic design, PCB layout, signal integrity, and other technical aspects. It is essential to follow best practices and guidelines to ensure proper functionality and reliability.

5. Are there any limitations to using daughterboards?

While daughterboards offer many benefits, there are some limitations to consider:

- Limited PCB area and component height due to vertical stacking

- Potential signal integrity challenges due to longer signal paths

- Increased power consumption and heat generation

- Higher overall system complexity and cost compared to single-board solutions

Despite these limitations, daughterboards remain a valuable tool for expanding system functionality and flexibility in many applications.

Conclusion

Daughterboards play a crucial role in expanding the functionality and flexibility of electronic systems. By providing a modular and space-efficient solution for adding features or customizing hardware, daughterboards enable systems to adapt to changing requirements and application needs. When designing with daughterboards, careful consideration must be given to connector selection, power management, signal integrity, thermal management, and mechanical design to ensure reliable and efficient operation.

As technology continues to advance, the use of daughterboards is likely to grow across various industries, from personal computing and embedded systems to industrial automation and aerospace. By understanding the principles and best practices of daughterboard design, engineers and system designers can create innovative and adaptable solutions that meet the ever-evolving demands of modern electronics.

No responses yet