Introduction to Daughter Board LEDs

Daughter boards, also known as expansion boards or add-on boards, are essential components in electronic systems that provide additional functionality or features to the main board. These boards often include various indicators, such as LEDs (Light Emitting Diodes), to communicate the status of power, programming, and other functions. In this article, we will dive deep into the world of daughter board power and program LEDs, exploring their importance, types, and applications.

Understanding the Role of LEDs on Daughter Boards

LEDs on daughter boards serve multiple purposes, including:

- Power Indication

- Programming Status

- Error Indication

- User Feedback

By providing visual cues, these LEDs help users and developers monitor the operation of the daughter board and diagnose any issues that may arise.

Types of LEDs Used on Daughter Boards

1. Power LEDs

Power LEDs are typically used to indicate the presence of power on the daughter board. These LEDs are connected to the power supply lines and illuminate when the board is receiving the correct voltage. The most common colors for power LEDs are:

- Green: Indicates that the board is receiving the correct voltage and is functioning properly.

- Red: Indicates that there is an issue with the power supply, such as insufficient voltage or incorrect polarity.

2. Program LEDs

Program LEDs are used to indicate the status of the programming process on the daughter board. These LEDs are controlled by the firmware or software running on the board and provide visual feedback during the programming process. Common colors and their meanings include:

- Yellow: Indicates that the board is in programming mode and is ready to receive new firmware.

- Blue: Indicates that the programming process is in progress.

- Green: Indicates that the programming process has been completed successfully.

- Red: Indicates that there was an error during the programming process.

3. Status LEDs

Status LEDs are used to indicate various states or conditions of the daughter board. These LEDs can be controlled by the firmware or software running on the board and can provide information about the board’s operation, such as:

- Data transmission or reception

- Error conditions

- User-defined states

The colors and meanings of status LEDs can vary depending on the specific application and the designer’s preferences.

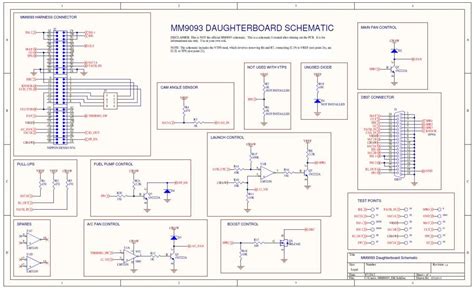

Designing with Daughter Board LEDs

When designing a daughter board, it is essential to consider the placement, color, and function of the LEDs carefully. Some best practices include:

- Choosing LED colors that are intuitive and easy to understand for users.

- Placing LEDs in visible locations on the board, making them easily accessible for monitoring.

- Using current-limiting resistors to protect the LEDs from excessive current and ensure reliable operation.

- Providing clear documentation on the meaning of each LED and how to interpret their states.

LED Circuit Design Considerations

When designing LED circuits for daughter boards, several factors must be taken into account:

-

Forward Voltage Drop: Each LED has a specific forward voltage drop that must be considered when selecting the appropriate current-limiting resistor.

-

Current Limiting: Current-limiting resistors are used to protect the LEDs from excessive current, which can cause damage or reduced lifespan. The resistor value can be calculated using Ohm’s law:

R = (Vsupply – VLED) / ILED

Where:

– R is the resistor value in ohms

– Vsupply is the supply voltage in volts

– VLED is the LED’s forward voltage drop in volts

– ILED is the desired LED current in amperes

- Brightness: The brightness of an LED is determined by the current flowing through it. Higher currents result in brighter LEDs but also increase power consumption and heat generation.

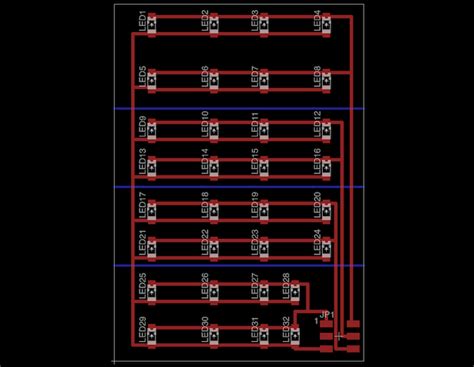

Example LED Circuit

Here’s an example of a simple LED circuit that can be used on a daughter board:

Vsupply

|

+

|

R

|

+----> LED Anode

|

|

GND <----+

In this circuit, the current-limiting resistor (R) is connected in series with the LED, and the cathode of the LED is connected to ground (GND). The value of the resistor is chosen based on the desired LED current and the forward voltage drop of the LED.

Applications of Daughter Board LEDs

Daughter board LEDs find applications in various fields, including:

- Consumer Electronics

- Industrial Control Systems

- Automotive Electronics

- Medical Devices

- Aerospace and Defense Systems

In each of these applications, LEDs play a crucial role in providing visual feedback, aiding in diagnostics, and enhancing user experiences.

Case Study: Daughter Board LEDs in a Medical Device

In a medical device, such as a patient monitor, daughter boards are often used to add functionality or provide additional connectivity options. LEDs on these daughter boards can serve multiple purposes:

- Power LEDs: Indicate that the daughter board is receiving the correct voltage and is functioning properly.

- Status LEDs: Indicate the status of the device, such as:

- Green: The device is operating normally.

- Yellow: The device is in standby mode.

-

Red: There is an error or malfunction that requires attention.

-

Data Transfer LEDs: Indicate when the daughter board is sending or receiving data from the main board or external devices.

By providing clear visual cues, these LEDs help medical professionals quickly identify the status of the device and take appropriate action if needed.

Troubleshooting Daughter Board LEDs

When troubleshooting issues with daughter board LEDs, consider the following steps:

-

Check the power supply: Ensure that the daughter board is receiving the correct voltage and that the power LED is illuminated.

-

Verify connections: Check that all connections between the daughter board and the main board are secure and properly seated.

-

Review documentation: Consult the daughter board’s documentation to understand the meaning of each LED and how to interpret their states.

-

Use a multimeter: Measure the voltage across the LED and current-limiting resistor to ensure they are within the expected ranges.

-

Check the firmware: If the issue is related to program or status LEDs, verify that the firmware is functioning correctly and that the LED control logic is implemented properly.

Frequently Asked Questions (FAQ)

- What is the purpose of a current-limiting resistor in an LED circuit?

-

A current-limiting resistor is used to protect the LED from excessive current, which can cause damage or reduced lifespan. It ensures that the current flowing through the LED remains within the specified limits.

-

Can I use any color LED for power, program, or status indication?

-

While you can technically use any color LED for these purposes, it is best to choose colors that are intuitive and easily recognizable. Common colors include green for power, yellow or blue for programming, and red for errors.

-

How do I calculate the value of the current-limiting resistor for an LED circuit?

-

To calculate the resistor value, use Ohm’s law: R = (Vsupply – VLED) / ILED, where R is the resistor value in ohms, Vsupply is the supply voltage in volts, VLED is the LED’s forward voltage drop in volts, and ILED is the desired LED current in amperes.

-

What should I do if the power LED on my daughter board is not illuminated?

-

First, check that the daughter board is receiving the correct voltage from the main board. If the voltage is correct, verify that the power LED is properly connected and that the current-limiting resistor is the correct value. If the issue persists, the LED itself may be damaged and need to be replaced.

-

Can I control the brightness of the LEDs on my daughter board?

- Yes, you can control the brightness of LEDs by adjusting the current flowing through them. This can be done by changing the value of the current-limiting resistor or by using pulse-width modulation (PWM) to control the LED’s on/off times rapidly.

Conclusion

Daughter board power and program LEDs play a vital role in providing visual feedback, aiding in diagnostics, and enhancing user experiences in various electronic systems. By understanding the types of LEDs used, their functions, and best practices for designing LED circuits, engineers can create more effective and user-friendly daughter boards. As technology continues to advance, the use of LEDs on daughter boards will remain an essential aspect of electronic design, ensuring that users and developers have the information they need to monitor and maintain these critical components.

No responses yet