Introduction to PCB BOM Management

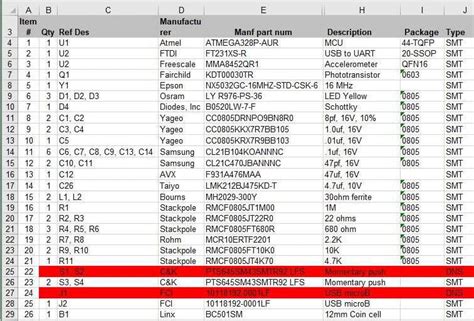

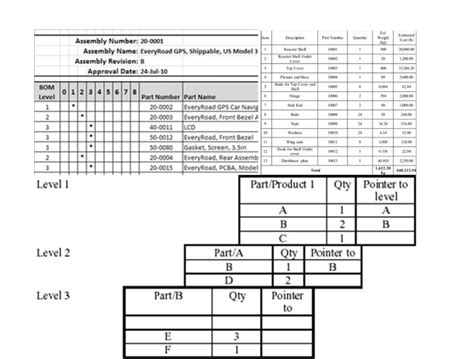

Printed Circuit Board (PCB) design is a complex process that involves numerous components, materials, and processes. One of the most critical aspects of PCB design is the Bill of Materials (BOM) management. A BOM is a comprehensive list of all the components, parts, and materials required to manufacture a PCB. Effective BOM management is essential for ensuring that the PCB design is accurate, cost-effective, and meets the desired specifications.

In this article, we will discuss why you need BOM management tools for PCB design and how they can help streamline your design process.

The Importance of PCB BOM Management

Ensuring Accuracy and Consistency

One of the primary reasons why you need BOM management tools for PCB design is to ensure accuracy and consistency throughout the design process. A BOM management tool allows you to create, maintain, and update your BOM in real-time, ensuring that all team members have access to the latest version of the BOM.

This is particularly important when working on complex PCB designs that involve multiple team members and stakeholders. With a BOM management tool, you can ensure that everyone is working with the same data, reducing the risk of errors and inconsistencies.

Reducing Costs and Improving Efficiency

Another key benefit of using BOM management tools for PCB design is that they can help reduce costs and improve efficiency. By automating many of the manual tasks associated with BOM management, such as data entry and validation, you can save time and reduce the risk of errors.

Additionally, BOM management tools can help you identify opportunities for cost savings by allowing you to compare prices from multiple suppliers and identify alternative components that may be more cost-effective.

Facilitating Collaboration and Communication

PCB design is often a collaborative process that involves multiple team members and stakeholders. BOM management tools can facilitate collaboration and communication by providing a centralized platform for sharing data and feedback.

With a BOM management tool, team members can easily access and update the BOM, adding comments and suggestions as needed. This can help streamline the design process and ensure that everyone is on the same page.

Key Features of PCB BOM Management Tools

Integration with Design Tools

One of the most important features of a PCB BOM management tool is its ability to integrate with your existing design tools. This allows you to easily import and export data between your BOM and your design files, reducing the risk of errors and ensuring that your BOM is always up-to-date.

Many BOM management tools offer integrations with popular PCB design software, such as Altium Designer, Eagle, and KiCad.

Automated Data Validation

Another key feature of PCB BOM management tools is automated data validation. This allows you to quickly identify and correct errors in your BOM, such as missing or incorrect part numbers, quantities, or descriptions.

Automated data validation can save you significant time and effort, particularly when working with large and complex BOMs.

Supplier Management

Effective BOM management also requires effective supplier management. BOM management tools can help you manage your supplier relationships by allowing you to track pricing, lead times, and availability for each component in your BOM.

This can help you make informed decisions about which suppliers to use and when to place orders, ensuring that you have the components you need when you need them.

Reporting and Analytics

Finally, BOM management tools often offer reporting and analytics capabilities that can help you track key metrics and identify areas for improvement. For example, you may be able to generate reports on component usage, cost trends, or supplier performance.

These insights can help you make data-driven decisions about your PCB design process, ultimately leading to better outcomes and more efficient use of resources.

Choosing the Right PCB BOM Management Tool

With so many PCB BOM management tools available, it can be challenging to know which one is right for your needs. Here are some key factors to consider when evaluating BOM management tools:

- Integration with your existing design tools

- Ease of use and user interface

- Automated data validation and error checking

- Supplier management features

- Reporting and analytics capabilities

- Scalability and flexibility to accommodate future growth

It’s also important to consider the level of support and training provided by the vendor, as well as the total cost of ownership over time.

Conclusion

In conclusion, BOM management is a critical component of PCB design that requires careful attention and management. By using BOM management tools, you can streamline your design process, reduce errors and inconsistencies, and ultimately create better PCBs faster and more cost-effectively.

When choosing a BOM management tool, it’s important to consider your specific needs and requirements, as well as the key features and capabilities of each tool. By taking the time to evaluate your options carefully, you can find the right tool to support your PCB design process and help you achieve your goals.

FAQs

1. What is a Bill of Materials (BOM) in PCB design?

A Bill of Materials (BOM) is a comprehensive list of all the components, parts, and materials required to manufacture a PCB. It includes details such as part numbers, quantities, descriptions, and supplier information.

2. Why is BOM management important in PCB design?

BOM management is important in PCB design because it ensures accuracy, consistency, and efficiency throughout the design process. Effective BOM management can help reduce errors, improve collaboration, and ultimately lead to better PCBs.

3. What are some key features to look for in a PCB BOM management tool?

Some key features to look for in a PCB BOM management tool include integration with existing design tools, automated data validation, supplier management capabilities, and reporting and analytics features.

4. How can BOM management tools help reduce costs in PCB design?

BOM management tools can help reduce costs in PCB design by automating manual tasks, identifying opportunities for cost savings through supplier comparison, and providing insights into component usage and cost trends.

5. What should I consider when choosing a PCB BOM management tool?

When choosing a PCB BOM management tool, you should consider factors such as integration with your existing design tools, ease of use, automated data validation capabilities, supplier management features, reporting and analytics capabilities, scalability, and total cost of ownership over time.

| Feature | Benefit |

|---|---|

| Integration with design tools | Ensures accuracy and consistency between BOM and design files |

| Automated data validation | Quickly identifies and corrects errors in the BOM |

| Supplier management | Tracks pricing, lead times, and availability for each component |

| Reporting and analytics | Provides insights into component usage, cost trends, and supplier performance |

No responses yet