What are Vias in PCB Design?

In printed circuit board (PCB) design, vias are small holes drilled through the board to allow electrical connections between different layers of the PCB. They are essential components in multi-layer PCBs, enabling the routing of signals and power between layers. Vias come in various types, such as through-hole vias, blind vias, and buried vias, each serving specific purposes in the PCB design process.

Types of Vias

| Via Type | Description |

|---|---|

| Through-hole Via | Extends through all layers of the PCB |

| Blind Via | Connects an outer layer to an inner layer, but does not go through the entire board |

| Buried Via | Connects inner layers without reaching the outer layers |

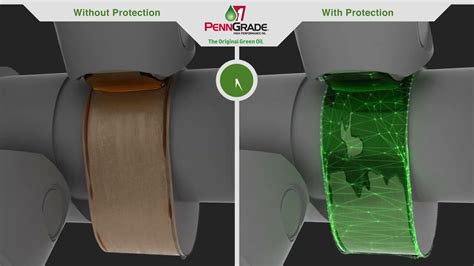

Importance of Via Protection

Via protection is a crucial aspect of PCB design and manufacturing. It ensures the reliability, durability, and performance of the PCB by addressing several key issues that can arise during the manufacturing process and the life cycle of the product. Some of the main reasons for protecting vias include:

- Preventing contamination

- Enhancing mechanical strength

- Improving electrical integrity

- Increasing thermal stability

- Facilitating the assembly process

Preventing Contamination

One of the primary reasons for protecting vias is to prevent contamination. During the PCB manufacturing process, various contaminants such as dust, debris, and chemicals can enter the vias, leading to several issues. These contaminants can cause:

- Electrical shorts

- Reduced insulation resistance

- Intermittent connections

- Corrosion of the via walls

By protecting the vias, you can minimize the risk of contamination and ensure the proper functioning of the PCB.

Methods for Preventing Contamination

- Via Tenting: Covering the via with solder mask on one or both sides of the PCB.

- Via Filling: Filling the via with a non-conductive epoxy or other filling materials.

- Via Capping: Covering the via with a conductive material, such as copper or silver.

Enhancing Mechanical Strength

Vias can be a source of mechanical weakness in a PCB, especially when they are located in areas subjected to stress or vibration. Unprotected vias can lead to:

- Cracking of the PCB substrate

- Delamination of the copper layers

- Fracturing of the via walls

By protecting the vias, you can enhance the mechanical strength of the PCB and reduce the risk of physical damage.

Methods for Enhancing Mechanical Strength

- Via Filling: Filling the via with a non-conductive epoxy or other filling materials.

- Via Plugging: Filling the via with a conductive material, such as copper or silver.

- Via Reinforcement: Adding additional copper plating to the via walls to increase their thickness and strength.

Improving Electrical Integrity

Via protection is essential for maintaining the electrical integrity of the PCB. Unprotected vias can cause several issues that affect the electrical performance of the board, such as:

- Signal integrity problems

- Impedance mismatches

- Crosstalk between adjacent vias

- Electromagnetic interference (EMI)

By protecting the vias, you can minimize these issues and ensure the proper functioning of the PCB.

Methods for Improving Electrical Integrity

- Via Shielding: Surrounding the via with a conductive material to create a Faraday cage, which reduces EMI and crosstalk.

- Via Stitching: Adding additional vias around the main via to create a low-impedance path for high-frequency signals.

- Via Fencing: Placing ground vias around signal vias to provide isolation and reduce crosstalk.

Increasing Thermal Stability

Vias play a crucial role in the thermal management of a PCB. They act as heat conduits, allowing heat to dissipate from components and heat-generating areas of the board. Unprotected vias can lead to:

- Localized hot spots

- Thermal stress on components

- Reduced lifespan of the PCB

By protecting the vias, you can improve the thermal stability of the PCB and ensure better heat dissipation.

Methods for Increasing Thermal Stability

- Via Filling: Filling the via with a thermally conductive material, such as silver-filled epoxy.

- Via Plugging: Filling the via with a conductive material, such as copper or silver.

- Thermal Via Arrays: Adding multiple vias in close proximity to create a low-thermal-resistance path for heat dissipation.

Facilitating the Assembly Process

Via protection can also facilitate the assembly process of the PCB. Unprotected vias can cause several issues during assembly, such as:

- Solder wicking into the via

- Difficulty in applying solder paste

- Inconsistent solder joint formation

By protecting the vias, you can minimize these issues and ensure a smoother assembly process.

Methods for Facilitating the Assembly Process

- Via Tenting: Covering the via with solder mask on the component side of the PCB to prevent solder wicking.

- Via Filling: Filling the via with a non-conductive epoxy to create a flat surface for solder paste application.

- Via Capping: Covering the via with a conductive material to create a solderable surface.

Choosing the Right Via Protection Method

Selecting the appropriate via protection method depends on several factors, such as:

- The application of the PCB

- The environmental conditions the PCB will be exposed to

- The electrical and thermal requirements of the PCB

- The manufacturing capabilities and cost constraints

It is essential to consider these factors and consult with the PCB manufacturer to determine the most suitable via protection method for your specific project.

Frequently Asked Questions (FAQ)

- What is the difference between via tenting and via filling?

-

Via tenting involves covering the via with solder mask on one or both sides of the PCB, while via filling involves filling the via with a non-conductive epoxy or other filling materials.

-

Can via protection affect the impedance of the PCB?

-

Yes, via protection methods such as via filling and via plugging can affect the impedance of the PCB. It is essential to consider the impact of via protection on the impedance during the design process.

-

How does via protection improve the thermal stability of the PCB?

-

Via protection methods, such as via filling with thermally conductive materials or via plugging with conductive materials, can improve the thermal stability of the PCB by creating low-thermal-resistance paths for heat dissipation.

-

Is via protection always necessary?

-

While via protection is generally recommended, it may not always be necessary. The decision to protect vias depends on the specific requirements and constraints of the PCB design, such as the application, environmental conditions, and manufacturing capabilities.

-

What are the cost implications of via protection?

- Via protection methods can add to the overall cost of PCB manufacturing. The cost implications depend on the specific protection method used and the volume of production. It is essential to consider the cost-benefit trade-offs when deciding on via protection for your PCB design.

Conclusion

Via protection is a critical aspect of PCB design and manufacturing. It addresses several key issues, such as preventing contamination, enhancing mechanical strength, improving electrical integrity, increasing thermal stability, and facilitating the assembly process. By choosing the appropriate via protection method based on the specific requirements of your PCB design, you can ensure the reliability, durability, and performance of your product. Always consult with your PCB manufacturer to determine the most suitable via protection approach for your project.

No responses yet