Introduction to VNA Measurements and PCB Substrates

When designing and manufacturing printed circuit boards (PCBs), it is crucial to understand the properties of the substrate material. The substrate, which is the foundation of the PCB, plays a significant role in determining the electrical performance, reliability, and overall quality of the final product. One powerful tool for analyzing and characterizing PCB substrates is the Vector Network Analyzer (VNA). VNA measurements provide valuable insights into the electrical properties of the substrate, enabling engineers to optimize their designs and ensure optimal performance.

In this article, we will explore the various aspects of VNA measurements and how they can help you gain a deeper understanding of your PCB substrate. We will discuss the principles behind VNA measurements, the key parameters that can be measured, and the practical applications of this knowledge in PCB design and manufacturing.

Understanding the Basics of VNA Measurements

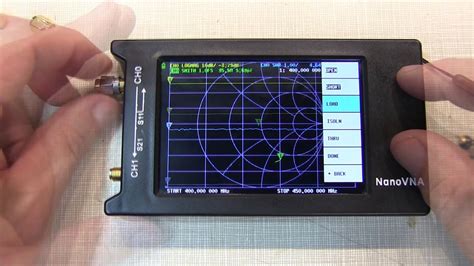

A Vector Network Analyzer is a sophisticated instrument that measures the electrical properties of a device under test (DUT) by analyzing the amplitude and phase of the transmitted and reflected signals. In the context of PCB substrates, VNA measurements provide information about the substrate’s dielectric constant (εr), loss tangent (tan δ), and other critical parameters.

The dielectric constant is a measure of the substrate’s ability to store electrical energy, while the loss tangent represents the energy dissipation in the substrate. These properties directly impact the signal propagation, impedance matching, and overall performance of the PCB.

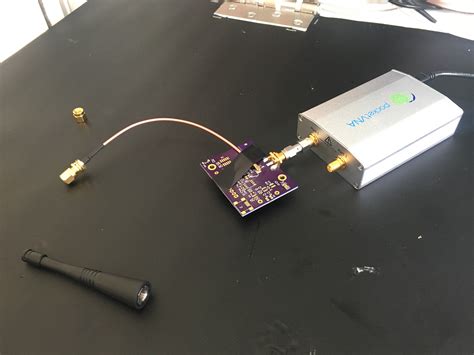

To perform VNA measurements on a PCB substrate, a test coupon or a dedicated test structure is typically used. The test coupon is a small piece of the substrate material with well-defined dimensions and a specific pattern of conductive traces. By measuring the S-parameters (scattering parameters) of the test coupon using a VNA, engineers can extract the dielectric constant and loss tangent of the substrate.

Key Parameters Measured by VNA

When conducting VNA measurements on PCB substrates, several key parameters can be obtained. These parameters provide valuable insights into the electrical properties of the substrate and help engineers make informed decisions during the design and manufacturing process.

1. Dielectric Constant (εr)

The dielectric constant, also known as relative permittivity, is a measure of the substrate’s ability to store electrical energy in an electric field. It is a dimensionless quantity that represents the ratio of the permittivity of the substrate to the permittivity of vacuum. The dielectric constant of a substrate directly influences the signal propagation speed, wavelength, and impedance of the PCB traces.

VNA measurements allow engineers to determine the dielectric constant of the substrate over a wide range of frequencies. This information is crucial for designing high-speed digital circuits, RF and microwave applications, and impedance-controlled PCBs.

2. Loss Tangent (tan δ)

The loss tangent, also known as the dissipation factor, is a measure of the energy dissipation in the substrate. It represents the ratio of the imaginary part of the complex permittivity to the real part. A higher loss tangent indicates greater energy loss and signal attenuation in the substrate.

VNA measurements provide the loss tangent of the substrate as a function of frequency. This information is essential for predicting signal integrity issues, such as attenuation and dispersion, in high-speed and high-frequency PCB designs.

3. Characteristic Impedance (Z0)

The characteristic impedance is a critical parameter in PCB design, particularly for controlled-impedance traces. It represents the impedance that a signal experiences when propagating along a transmission line. Matching the characteristic impedance of the traces to the desired value (e.g., 50 Ω or 100 Ω) is essential for minimizing reflections and ensuring proper signal integrity.

VNA measurements can be used to determine the characteristic impedance of the PCB traces based on the substrate properties and the trace geometry. By extracting the dielectric constant and loss tangent of the substrate, engineers can calculate the characteristic impedance and optimize the trace dimensions accordingly.

4. Insertion Loss (IL)

Insertion loss refers to the reduction in signal power as it propagates through the PCB substrate and traces. It is a measure of the attenuation experienced by the signal due to dielectric losses, conductor losses, and other factors.

VNA measurements can provide the insertion loss of the PCB substrate and traces as a function of frequency. This information is crucial for predicting the signal integrity performance of the PCB, particularly in high-speed and high-frequency applications.

Practical Applications of VNA Measurements in PCB Design and Manufacturing

The knowledge gained from VNA measurements of PCB substrates has numerous practical applications in the design and manufacturing process. Let’s explore some of the key areas where this information can be leveraged to improve PCB performance and reliability.

1. Material Selection

VNA measurements provide valuable insights into the electrical properties of different substrate materials. By comparing the dielectric constant, loss tangent, and other parameters of various substrates, engineers can make informed decisions when selecting the most suitable material for their specific application.

For example, in high-speed digital designs, a substrate with a low dielectric constant and low loss tangent is desirable to minimize signal propagation delay and attenuation. On the other hand, for RF and microwave applications, substrates with stable dielectric properties over a wide frequency range are preferred.

2. Impedance Control

Controlling the characteristic impedance of PCB traces is critical for ensuring proper signal integrity and minimizing reflections. VNA measurements of the substrate’s dielectric constant and loss tangent enable engineers to accurately calculate the required trace dimensions to achieve the desired characteristic impedance.

By utilizing the extracted substrate properties, PCB design tools can automatically adjust the trace width and spacing to maintain a consistent characteristic impedance throughout the board. This process, known as impedance control, is essential for high-speed digital interfaces, such as DDR memory, PCIe, and USB.

3. Signal Integrity Analysis

VNA measurements provide valuable data for signal integrity analysis and simulation. By incorporating the substrate’s dielectric constant and loss tangent into circuit simulation models, engineers can accurately predict the behavior of signals propagating through the PCB.

Signal integrity simulations help identify potential issues, such as reflections, crosstalk, and attenuation, before the PCB is manufactured. This allows for proactive design optimizations, such as adjusting trace routing, implementing impedance matching techniques, or adding termination components, to mitigate signal integrity problems.

4. Manufacturing Process Optimization

VNA measurements can also be used to optimize the PCB manufacturing process. By monitoring the substrate properties during production, manufacturers can ensure consistent quality and performance across different batches of PCBs.

For example, if the dielectric constant or loss tangent of the substrate deviates from the specified values, it can indicate issues with the material composition, lamination process, or environmental conditions. By identifying these variations early in the manufacturing process, corrective actions can be taken to maintain the desired electrical properties of the substrate.

5. Quality Control and Troubleshooting

VNA measurements serve as a powerful tool for quality control and troubleshooting of PCBs. By comparing the measured substrate properties against the specified values, engineers can identify any discrepancies or anomalies that may impact the performance of the PCB.

In case of PCB failures or unexpected behavior, VNA measurements can help diagnose the root cause of the problem. By analyzing the substrate properties and comparing them with the design specifications, engineers can determine if the issue is related to the substrate material, manufacturing process, or design flaws.

FAQs

-

Q: What is a Vector Network Analyzer (VNA)?

A: A Vector Network Analyzer is an instrument that measures the electrical properties of a device under test (DUT) by analyzing the amplitude and phase of the transmitted and reflected signals. It is commonly used to characterize the performance of electronic components, including PCB substrates. -

Q: Why are VNA measurements important for PCB substrates?

A: VNA measurements provide valuable insights into the electrical properties of PCB substrates, such as the dielectric constant and loss tangent. These properties directly impact the signal propagation, impedance matching, and overall performance of the PCB. By understanding these properties, engineers can optimize their designs and ensure optimal performance. -

Q: How are VNA measurements performed on PCB substrates?

A: To perform VNA measurements on a PCB substrate, a test coupon or a dedicated test structure is typically used. The test coupon is a small piece of the substrate material with well-defined dimensions and a specific pattern of conductive traces. By measuring the S-parameters of the test coupon using a VNA, engineers can extract the dielectric constant and loss tangent of the substrate. -

Q: What are the key parameters measured by VNA for PCB substrates?

A: The key parameters measured by VNA for PCB substrates include the dielectric constant (εr), loss tangent (tan δ), characteristic impedance (Z0), and insertion loss (IL). These parameters provide valuable information about the substrate’s ability to store and dissipate electrical energy, as well as its impact on signal propagation and integrity. -

Q: How can VNA measurements be applied in PCB design and manufacturing?

A: VNA measurements have numerous practical applications in PCB design and manufacturing. They can be used for material selection, impedance control, signal integrity analysis, manufacturing process optimization, and quality control. By leveraging the knowledge gained from VNA measurements, engineers can make informed decisions, optimize their designs, and ensure the reliability and performance of the final PCB product.

Conclusion

VNA measurements are a powerful tool for understanding and characterizing the electrical properties of PCB substrates. By measuring key parameters such as the dielectric constant, loss tangent, characteristic impedance, and insertion loss, engineers gain valuable insights into the substrate’s behavior and its impact on signal propagation and integrity.

The knowledge obtained from VNA measurements can be applied in various aspects of PCB design and manufacturing, including material selection, impedance control, signal integrity analysis, process optimization, and quality control. By leveraging this information, engineers can make informed decisions, optimize their designs, and ensure the reliability and performance of the final PCB product.

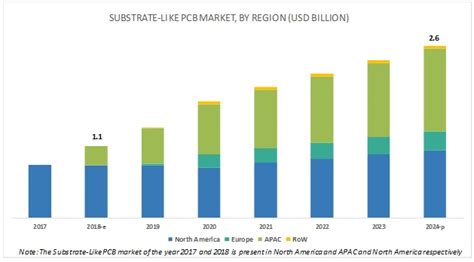

As the demands for high-speed, high-frequency, and high-density PCBs continue to grow, the importance of accurate and reliable VNA measurements becomes even more critical. By investing in VNA characterization of PCB substrates and incorporating the obtained knowledge into the design and manufacturing process, companies can stay ahead of the curve and deliver cutting-edge PCB solutions to their customers.

In conclusion, VNA measurements are an essential tool for anyone involved in PCB design and manufacturing. By understanding the principles behind VNA measurements, the key parameters measured, and their practical applications, engineers can unlock the full potential of their PCB substrates and create high-performance, reliable products that meet the ever-increasing demands of the electronics industry.

No responses yet