Introduction to RAM in PCB Design

Random Access Memory (RAM) is a crucial component in any electronic device that requires quick access to temporary data storage. In the context of Printed Circuit Board (PCB) design, choosing the right type of RAM can significantly impact the performance, cost, and overall functionality of the final product. Two common types of RAM used in PCB designs are Synchronous Dynamic RAM (SDRAM) and Double Data Rate (DDR) RAM. In this article, we will explore the differences between SDRAM and DDR RAM, their advantages and disadvantages, and factors to consider when selecting the appropriate RAM for your PCB design.

Understanding SDRAM

What is SDRAM?

SDRAM, or Synchronous Dynamic Random Access Memory, is a type of RAM that synchronizes its operations with the system clock. This synchronization allows for faster data access and processing compared to its predecessor, asynchronous DRAM. SDRAM is designed to work in sync with the CPU clock, enabling it to keep up with the processor’s speed and provide a steady flow of data.

Advantages of SDRAM

- Faster data access compared to asynchronous DRAM

- Lower power consumption than asynchronous DRAM

- Relatively inexpensive compared to newer RAM technologies

- Widely available and compatible with many systems

Disadvantages of SDRAM

- Limited bandwidth compared to newer RAM technologies

- Higher latency than DDR RAM

- Requires frequent refresh cycles to maintain data integrity

Understanding DDR RAM

What is DDR RAM?

DDR RAM, or Double Data Rate Random Access Memory, is an advanced version of SDRAM that can transfer data twice per clock cycle. This doubling of the data transfer rate allows DDR RAM to achieve higher bandwidth and lower latency compared to SDRAM. DDR RAM has evolved through several generations, including DDR, DDR2, DDR3, and DDR4, each offering improvements in speed, capacity, and power efficiency.

Advantages of DDR RAM

- Higher bandwidth than SDRAM

- Lower latency than SDRAM

- Improved power efficiency with each new generation

- Allows for faster system performance and multitasking

Disadvantages of DDR RAM

- More expensive than SDRAM

- Requires compatible motherboards and processors

- May generate more heat than SDRAM due to higher clock speeds

Factors to Consider When Choosing Between SDRAM and DDR RAM

System Requirements

The first factor to consider when choosing between SDRAM and DDR RAM is the system requirements of your PCB design. Determine the minimum and maximum RAM capacity needed, as well as the required speed and bandwidth. If your design demands high-performance computing or fast data processing, DDR RAM may be the better choice. However, if your design has modest memory requirements and cost is a primary concern, SDRAM may suffice.

Compatibility

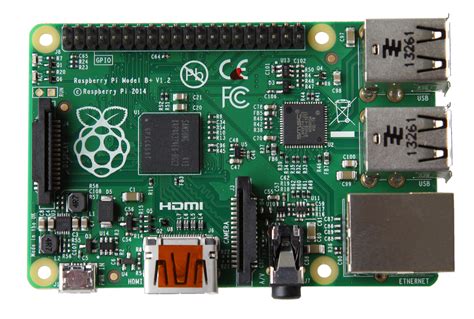

Ensure that the chosen RAM type is compatible with the other components in your PCB design, such as the processor, motherboard, and chipset. DDR RAM generations have specific pin configurations and voltage requirements that must match the supporting hardware. SDRAM, being an older technology, may have broader compatibility with legacy systems.

Power Consumption

Consider the power consumption of the RAM type in relation to your PCB design’s power budget. SDRAM generally consumes less power than DDR RAM, which can be advantageous for battery-powered or energy-efficient devices. However, newer generations of DDR RAM have made significant strides in reducing power consumption through advanced power management techniques.

Cost

The cost of the RAM type is another important factor to consider, especially for mass-produced or budget-constrained designs. SDRAM is typically less expensive than DDR RAM, making it a more cost-effective option for simple or low-cost PCB designs. However, the cost difference between SDRAM and DDR RAM has decreased over time, making DDR RAM a more viable choice for a wider range of applications.

Future-Proofing

When designing a PCB, it’s essential to consider the future-proofing aspect of your component choices. While SDRAM may be sufficient for current requirements, it may limit the upgradeability and longevity of your design. DDR RAM, with its continuous advancements and higher performance, may provide a more future-proof solution that can accommodate evolving system demands.

PCB Design Considerations for RAM Integration

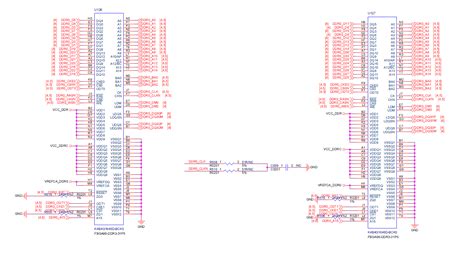

Signal Integrity

Proper signal integrity is crucial when integrating RAM into your PCB design. High-speed RAM interfaces require careful attention to trace routing, impedance matching, and termination techniques. Ensure that the PCB layout follows best practices for minimizing signal reflections, crosstalk, and noise, which can adversely affect RAM performance and reliability.

Power Delivery

Robust power delivery is essential for stable RAM operation. Design the power distribution network (PDN) to provide clean and stable voltage to the RAM components. Use appropriate decoupling capacitors and power plane layouts to minimize voltage fluctuations and ensure sufficient current delivery during high-demand periods.

Thermal Management

RAM modules, especially high-performance DDR RAM, can generate significant heat during operation. Adequate thermal management is necessary to prevent overheating and ensure reliable performance. Consider the placement of RAM components in relation to other heat-generating components, and incorporate appropriate cooling solutions, such as heatsinks or fans, if required.

EMI/EMC Compliance

Electromagnetic interference (EMI) and electromagnetic compatibility (EMC) are important considerations when integrating RAM into your PCB design. High-speed RAM interfaces can be sources of electromagnetic emissions that may interfere with other components or exceed regulatory limits. Implement proper shielding, grounding, and filtering techniques to mitigate EMI and ensure EMC compliance.

Comparing SDRAM and DDR RAM Performance

To better understand the performance differences between SDRAM and DDR RAM, let’s compare some key specifications:

| Specification | SDRAM | DDR RAM |

|---|---|---|

| Data Rate | Single | Double |

| Clock Speed | 100-200 MHz | 400-3200 MHz |

| Bandwidth | 0.8-1.6 GB/s | 3.2-25.6 GB/s |

| Latency (CAS) | 2-3 clocks | 5-19 clocks |

| Voltage | 3.3 V | 1.8-1.2 V |

| Power Consumption | Moderate | High |

As evident from the table, DDR RAM offers significantly higher clock speeds, bandwidth, and overall performance compared to SDRAM. However, DDR RAM also has higher latency and power consumption, which may be factors to consider based on your specific design requirements.

FAQs

-

Q: Can I use SDRAM and DDR RAM interchangeably in my PCB design?

A: No, SDRAM and DDR RAM are not interchangeable. They have different pin configurations, voltage requirements, and communication protocols. Your PCB design must be tailored to the specific RAM type you choose. -

Q: Is SDRAM still relevant in modern PCB designs?

A: While SDRAM is an older technology, it still finds use in certain applications where cost and compatibility with legacy systems are primary concerns. However, for most modern PCB designs, DDR RAM offers superior performance and future-proofing. -

Q: What is the latest generation of DDR RAM?

A: As of 2021, the latest generation of DDR RAM is DDR5. DDR5 offers even higher bandwidth, lower power consumption, and improved features compared to its predecessor, DDR4. -

Q: How does the choice of RAM affect the overall system performance?

A: The choice of RAM significantly impacts system performance. Faster RAM with higher bandwidth allows for quicker data access and processing, resulting in improved overall system responsiveness and multitasking capabilities. -

Q: Can I mix different generations of DDR RAM in the same PCB design?

A: No, it is not recommended to mix different generations of DDR RAM in the same PCB design. Each generation has specific electrical and timing characteristics that may not be compatible with each other, leading to instability or performance issues.

Conclusion

Choosing between SDRAM and DDR RAM in your PCB design requires careful consideration of various factors, including system requirements, compatibility, power consumption, cost, and future-proofing. While SDRAM offers a cost-effective solution for basic memory needs, DDR RAM provides superior performance, bandwidth, and upgradeability for demanding applications.

When integrating RAM into your PCB design, pay close attention to signal integrity, power delivery, thermal management, and EMI/EMC compliance to ensure optimal performance and reliability. By understanding the differences between SDRAM and DDR RAM and following best practices for PCB design, you can make an informed decision that aligns with your specific project requirements and goals.

As technology continues to advance, staying up-to-date with the latest RAM developments and their impact on PCB design is crucial. By leveraging the capabilities of modern RAM technologies, such as DDR5, you can future-proof your designs and deliver high-performance, energy-efficient, and reliable electronic products to the market.

No responses yet