Understanding the Component Shortage

The electronic component shortage is a multifaceted issue triggered by several factors, including:

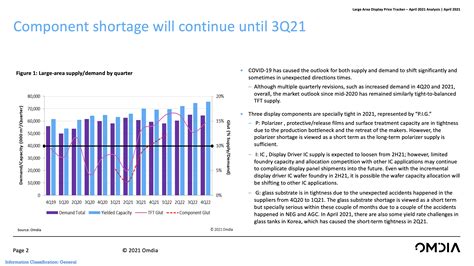

- Increased demand for electronic devices due to the COVID-19 pandemic

- Limited production capacity of semiconductor manufacturers

- Trade tensions and tariffs between major economies

- Natural disasters and factory shutdowns affecting production

These factors have led to a global shortage of essential components such as microcontrollers, resistors, capacitors, and connectors, making it difficult for manufacturers to meet the growing demand for electronic products.

Impact of the Component Shortage on Industries

The component shortage has had a significant impact on various industries, including:

| Industry | Impact |

|---|---|

| Automotive | Production delays, increased costs, reduced vehicle sales |

| Consumer Electronics | Longer lead times, higher prices, limited product availability |

| Medical Devices | Delayed product launches, supply chain disruptions, increased costs |

| Industrial Equipment | Delayed projects, increased costs, reduced productivity |

To mitigate the impact of the component shortage, industries are adopting various strategies such as redesigning products, exploring alternative components, and investing in inventory management systems.

Design Strategies for Navigating the Component Shortage

Designers and engineers can employ several strategies to minimize the impact of the component shortage on their projects:

1. Design for Availability

When designing new products, prioritize components that are readily available and have multiple sources. This approach may require compromising on performance or features, but it can help ensure a more stable supply chain.

2. Embrace Flexibility in Component Selection

Be open to using alternative components with similar specifications when the preferred component is unavailable. This may involve redesigning certain aspects of the product to accommodate the new component.

3. Collaborate with Suppliers

Establish strong relationships with component suppliers and distributors to stay informed about availability, lead times, and potential alternatives. Collaborating closely with suppliers can help secure a more stable supply of components.

4. Optimize Inventory Management

Implement robust inventory management systems to monitor component availability, track lead times, and forecast demand. This can help identify potential shortages early and allow for proactive measures to be taken.

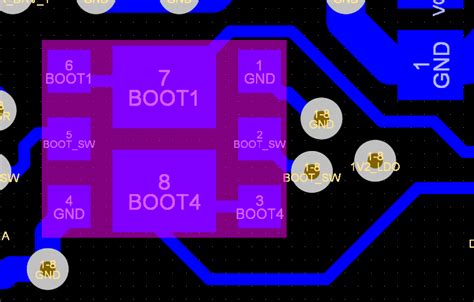

5. Consider Modular Design

Design products using modular architecture, allowing for easier substitution of components when necessary. This approach can also facilitate faster product updates and reduce overall development time.

Printed Electronics: A Potential Solution

Printed electronics is an emerging technology that involves printing conductive inks onto various substrates to create electronic circuits and components. This technology offers several advantages that can help alleviate the impact of the component shortage:

1. Rapid Prototyping and Customization

Printed electronics enables quick prototyping and customization of electronic circuits, reducing the reliance on traditional component suppliers. Designers can create custom components and circuits in-house, tailored to their specific requirements.

2. Reduced Complexity and Cost

By printing electronic circuits directly onto substrates, printed electronics can reduce the complexity and cost of manufacturing. This can help mitigate the impact of increased component prices due to the shortage.

3. Flexibility in Material Selection

Printed electronics allows for the use of a wide range of materials, including flexible and stretchable substrates, which can open up new possibilities for product design and functionality.

4. Potential for In-House Production

With the right equipment and expertise, companies can bring the production of certain electronic components in-house using printed electronics technology. This can help reduce the reliance on external suppliers and mitigate the impact of the component shortage.

Design Resources for Printed Electronics

To leverage the benefits of printed electronics, designers and engineers can access various resources and tools:

1. Printed Electronics Design Software

There are several software tools available for designing printed electronic circuits, such as:

- AutoCAD (Autodesk)

- EAGLE (Autodesk)

- Altium Designer (Altium)

- Tinkercad (Autodesk)

These tools offer features specifically tailored for printed electronics design, including conductive ink selection, substrate compatibility, and circuit simulation.

2. Printed Electronics Prototyping Services

Several companies offer prototyping services for printed electronics, allowing designers to test their designs without investing in expensive equipment. Some popular services include:

- Printed Electronics Ltd.

- Quad Industries

- Screentec

- TactoTek

These services provide rapid prototyping, small-batch production, and design support for printed electronics projects.

3. Online Learning Resources

To gain knowledge and skills in printed electronics design, designers can access various online learning resources, such as:

- Printed Electronics: A Hands-On Guide to Designing and Manufacturing (LinkedIn Learning)

- Introduction to Printed Electronics (Coursera)

- Printed Electronics: From Lab to Fab (edX)

- Printed Electronics: Design and Applications (Udemy)

These courses cover the fundamentals of printed electronics, design principles, manufacturing processes, and real-world applications.

Frequently Asked Questions (FAQ)

1. How long is the component shortage expected to last?

The duration of the component shortage is difficult to predict, as it depends on various factors such as global demand, production capacity, and geopolitical events. Some experts estimate that the shortage may last until 2023 or beyond.

2. Are there any components that are less affected by the shortage?

While the shortage has impacted a wide range of components, some components such as resistors and capacitors are relatively less affected compared to more complex components like microcontrollers and semiconductors.

3. Can printed electronics completely replace traditional components?

Printed electronics is not a complete replacement for traditional components, as it has limitations in terms of performance, reliability, and scalability. However, it can complement traditional components and provide alternatives for certain applications.

4. What are the challenges in adopting printed electronics technology?

Some challenges in adopting printed electronics include limited material options, lower performance compared to traditional components, and the need for specialized knowledge and equipment.

5. How can designers stay updated on the component shortage situation?

Designers can stay informed about the component shortage by regularly monitoring industry news, attending webinars and conferences, and maintaining close communication with suppliers and distributors.

Conclusion

The electronic component shortage presents significant challenges for industries worldwide, but by adopting strategic design approaches and exploring emerging technologies like printed electronics, designers and engineers can navigate through this crisis. Leveraging design resources, collaborating with suppliers, and staying informed about the latest developments in the industry can help mitigate the impact of the shortage and ensure the continued development of innovative electronic products.

As the demand for electronic devices continues to grow, it is crucial for the industry to invest in capacity expansion, supply chain resilience, and the development of alternative technologies. By working together and embracing new solutions, we can overcome the challenges posed by the component shortage and drive the future of electronics innovation.

No responses yet