Introduction to Rapid Prototyping

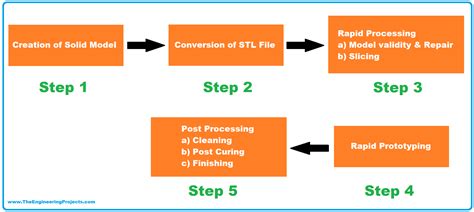

Rapid prototyping is a process of quickly creating a physical model or prototype of a product or component using various technologies such as 3D printing, CNC machining, and injection molding. This approach allows designers and engineers to test and refine their designs before committing to full-scale production, saving time and resources while improving the overall quality of the final product.

In the electronics industry, rapid prototyping has become an essential tool for developing new products and bringing them to market faster. With the help of advanced software and hardware tools, electronics experts like Duane Benson can create functional prototypes of circuit boards, enclosures, and other components in a matter of days or even hours.

Benefits of Rapid Prototyping in Electronics

- Faster iteration and refinement of designs

- Reduced development costs and time-to-market

- Improved communication between design and manufacturing teams

- Early detection and correction of design flaws

- Increased flexibility and adaptability to changing requirements

Rapid Prototyping Technologies for Electronics

3D Printing

3D printing is a popular rapid prototyping technology that allows designers to create physical objects from digital 3D models. In electronics, 3D printing is commonly used to create enclosures, connectors, and other mechanical components. Some advantages of 3D printing include:

- Quick turnaround times

- Ability to create complex geometries

- Wide range of materials, including plastics, metals, and ceramics

- Cost-effective for low-volume production

CNC Machining

CNC (Computer Numerical Control) machining is a subtractive manufacturing process that uses computer-controlled tools to remove material from a solid block of material, such as aluminum or steel. CNC machining is often used to create high-precision metal parts for electronics, such as heat sinks, chassis, and brackets. Benefits of CNC machining include:

- High accuracy and repeatability

- Ability to work with a wide range of materials

- Suitable for medium to high-volume production

- Excellent surface finishes

Injection Molding

Injection molding is a manufacturing process that involves injecting molten plastic into a mold cavity to create a desired shape. In electronics, injection molding is commonly used to create plastic enclosures, connectors, and other components. Advantages of injection molding include:

- High-volume production capability

- Consistent quality and repeatability

- Wide range of plastic materials and colors

- Ability to create complex shapes with fine details

Duane Benson’s Tips for Successful Rapid Prototyping in Electronics

- Start with a clear understanding of your design requirements and constraints

- Choose the appropriate rapid prototyping technology based on your needs and budget

- Use high-quality CAD software to create accurate 3D models of your components

- Collaborate closely with your manufacturing partners to ensure smooth transition from prototyping to production

- Test and validate your prototypes thoroughly before moving to the next stage of development

Case Studies: Successful Rapid Prototyping Projects in Electronics

Project 1: Wireless IoT Sensor Node

In this project, Duane Benson and his team developed a compact, low-power wireless sensor node for IoT applications. They used 3D printing to create a custom enclosure that housed the PCB, battery, and sensors. The team also used CNC machining to fabricate a small heatsink for the device’s microcontroller. By leveraging rapid prototyping technologies, they were able to create a functional prototype in just two weeks, allowing them to quickly test and refine the design before moving to full-scale production.

Project 2: Automotive Infotainment System

For this project, Duane Benson collaborated with an automotive manufacturer to develop a next-generation infotainment system. The team used injection molding to create a sleek, durable plastic enclosure for the system’s display and electronics. They also used 3D printing to prototype various buttons and knobs for the user interface. By utilizing rapid prototyping, the team was able to create multiple iterations of the design quickly, incorporating feedback from user testing and refining the system’s functionality and aesthetics.

Rapid Prototyping and Manufacturing: Best Practices

- Design for manufacturability: Consider the limitations and capabilities of your chosen manufacturing process when designing your components.

- Use standard components and materials whenever possible to reduce costs and lead times.

- Incorporate design for assembly (DFA) principles to streamline the assembly process and minimize errors.

- Establish clear communication channels between design and manufacturing teams to avoid misunderstandings and delays.

- Implement a robust quality control process to ensure that your prototypes and final products meet your specifications and performance requirements.

Future Trends in Rapid Prototyping for Electronics

As rapid prototyping technologies continue to evolve, we can expect to see several exciting developments in the electronics industry:

- Increased adoption of multi-material 3D printing, allowing for the creation of more complex and functional prototypes

- Integration of artificial intelligence and machine learning to optimize design and manufacturing processes

- Development of new materials with enhanced properties, such as high thermal conductivity or electromagnetic shielding

- Expansion of rapid prototyping capabilities to include embedded electronics and printed circuit structures

Frequently Asked Questions (FAQ)

-

Q: How long does it typically take to create a functional prototype using rapid prototyping technologies?

A: The time required to create a functional prototype depends on various factors, such as the complexity of the design, the chosen rapid prototyping technology, and the availability of materials and resources. In general, simple prototypes can be created in a matter of days, while more complex designs may take several weeks. -

Q: What are the costs associated with rapid prototyping in electronics?

A: The costs of rapid prototyping in electronics vary depending on the technology used, the size and complexity of the components, and the quantity of prototypes required. 3D printing and CNC machining are generally more cost-effective for low-volume production, while injection molding is more suitable for high-volume production. It’s essential to consider both the upfront costs and the long-term benefits of rapid prototyping when evaluating the overall cost-effectiveness of the approach. -

Q: How do I choose the right rapid prototyping technology for my electronics project?

A: When selecting a rapid prototyping technology for your electronics project, consider factors such as the required materials, the desired level of detail and accuracy, the expected production volume, and your budget. 3D printing is often a good choice for creating quick, low-cost prototypes of plastic components, while CNC machining is better suited for high-precision metal parts. Injection molding is ideal for high-volume production of plastic components with consistent quality. -

Q: Can rapid prototyping be used for creating functional electronic circuits?

A: Yes, rapid prototyping technologies can be used to create functional electronic circuits. For example, 3D printing can be used to create conductive traces and embedded components, allowing for the creation of simple circuits. Additionally, rapid PCB Prototyping services can quickly fabricate custom circuit boards based on your design files, enabling you to test and refine your electronic designs. -

Q: How can I ensure a smooth transition from rapid prototyping to full-scale production?

A: To ensure a smooth transition from rapid prototyping to full-scale production, it’s essential to work closely with your manufacturing partners throughout the development process. This includes sharing accurate design files, discussing materials and processes, and establishing clear quality control standards. It’s also important to consider the scalability of your design and choose rapid prototyping technologies that align with your long-term manufacturing strategy.

Conclusion

Rapid prototyping has revolutionized the way electronics products are designed and developed, enabling faster innovation, reduced costs, and improved product quality. By leveraging technologies such as 3D printing, CNC machining, and injection molding, electronics experts like Duane Benson can create functional prototypes quickly and efficiently, allowing for iterative design refinement and accelerated time-to-market.

As the electronics industry continues to evolve, staying up-to-date with the latest rapid prototyping technologies and best practices is essential for success. By following the tips and insights provided by experienced professionals like Duane Benson, designers and engineers can harness the power of rapid prototyping to create innovative, high-quality electronics products that meet the ever-changing needs of the market.

No responses yet