Introduction to Signal Delay on Printed Circuit Boards

Signal delay is a critical factor to consider when designing and manufacturing printed circuit boards (PCBs). It refers to the time it takes for a signal to travel from one point to another on the PCB. There are two main types of signal delay: propagation delay and transmission delay. Additionally, analog signal resonance can also impact signal integrity and timing on PCBs. Understanding and managing these factors is essential for ensuring proper functionality and performance of electronic devices.

What is Propagation Delay?

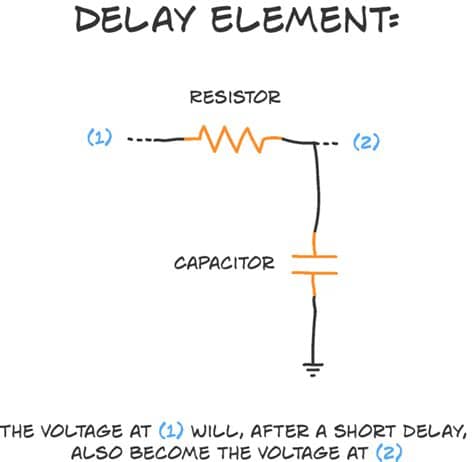

Propagation delay, also known as gate delay, is the time it takes for a signal to travel through a single logic gate or circuit element. It is determined by the physical properties of the gate, such as its transistor size, capacitance, and resistance. Propagation delay is typically measured in nanoseconds (ns) and can vary depending on factors such as temperature, voltage, and manufacturing process variations.

What is Transmission Delay?

Transmission delay, also referred to as interconnect delay or wire delay, is the time it takes for a signal to travel along a conductive trace or wire on the PCB. It is influenced by the physical properties of the trace, such as its length, width, thickness, and dielectric constant of the surrounding material. Transmission delay becomes increasingly significant as trace lengths increase and signal frequencies rise.

The Impact of Analog Signal Resonance

Analog signal resonance occurs when the frequency of a signal matches the natural resonant frequency of the PCB or its components. This can lead to signal amplification, distortion, and unwanted oscillations. Resonance issues are particularly problematic for high-frequency analog signals and can degrade signal integrity, leading to system malfunctions or failures.

Factors Affecting Signal Delay on PCBs

Several factors contribute to signal delay on PCBs. Understanding these factors is crucial for minimizing delay and ensuring optimal signal integrity.

PCB Material Properties

The choice of PCB material significantly impacts signal delay. The dielectric constant (Dk) and dissipation factor (Df) of the material determine the speed at which signals propagate through the board. Materials with lower Dk values, such as Rogers RO4000 series or Isola IS410, allow for faster signal propagation compared to standard FR-4 material.

| Material | Dielectric Constant (Dk) | Dissipation Factor (Df) |

|---|---|---|

| FR-4 | 4.5 | 0.02 |

| Rogers RO4003 | 3.38 | 0.0027 |

| Isola IS410 | 3.65 | 0.0030 |

Trace Geometry and Routing

The geometry and routing of traces on the PCB play a crucial role in signal delay. Longer traces introduce more transmission delay, while narrower traces have higher resistance and can lead to increased propagation delay. Additionally, the spacing between traces and their proximity to ground planes affects the characteristic impedance and delay of the signals.

| Trace Width (mils) | Characteristic Impedance (Ω) | Propagation Delay (ps/inch) |

|---|---|---|

| 5 | 93 | 142 |

| 10 | 68 | 127 |

| 20 | 48 | 115 |

Component Selection and Placement

The choice and placement of components on the PCB can impact signal delay. High-speed digital components, such as FPGAs and processors, often have specific requirements for managing propagation delay and minimizing skew between signals. Proper placement and routing techniques, such as length matching and delay equalization, are necessary to ensure synchronization and prevent timing issues.

Strategies for Managing Signal Delay

To mitigate the impact of signal delay on PCB performance, designers can employ various strategies and techniques.

Length Matching and Delay Equalization

Length matching involves ensuring that traces carrying related signals have equal lengths, minimizing skew and maintaining signal synchronization. This is particularly important for high-speed parallel interfaces like DDR memory or multi-lane serial links. Delay equalization techniques, such as serpentine routing or using delay lines, can be used to fine-tune the delay of individual signals and achieve precise timing relationships.

Impedance Control and Termination

Controlling the characteristic impedance of traces is essential for managing signal integrity and minimizing reflections that can cause signal distortion and delay. Proper termination techniques, such as series termination or parallel termination, help to match the impedance of the trace to the source and load impedances, reducing reflections and ensuring clean signal transitions.

| Termination Type | Description |

|---|---|

| Series | Resistor placed near the source to match the trace impedance |

| Parallel | Resistor placed at the load to match the trace impedance |

| AC | Capacitor and resistor network to provide high-frequency termination |

Simulation and Analysis Tools

Using simulation and analysis tools is critical for predicting and optimizing signal delay on PCBs. Tools such as Mentor Graphics HyperLynx or Cadence Sigrity allow designers to perform pre-layout and post-layout simulations, analyzing propagation delay, transmission delay, and signal integrity issues. These tools help identify potential problems early in the design process, enabling designers to make necessary adjustments before manufacturing.

FAQ

1. What is the difference between propagation delay and transmission delay?

Propagation delay refers to the time it takes for a signal to travel through a single logic gate or circuit element, while transmission delay is the time it takes for a signal to travel along a conductive trace or wire on the PCB.

2. How does PCB material choice affect signal delay?

The dielectric constant (Dk) and dissipation factor (Df) of the PCB material determine the speed at which signals propagate through the board. Materials with lower Dk values allow for faster signal propagation compared to standard FR-4 material.

3. What is the impact of analog signal resonance on PCBs?

Analog signal resonance can lead to signal amplification, distortion, and unwanted oscillations when the frequency of a signal matches the natural resonant frequency of the PCB or its components. This can degrade signal integrity and cause system malfunctions or failures.

4. How can length matching and delay equalization help manage signal delay?

Length matching ensures that traces carrying related signals have equal lengths, minimizing skew and maintaining signal synchronization. Delay equalization techniques, such as serpentine routing or using delay lines, can be used to fine-tune the delay of individual signals and achieve precise timing relationships.

5. Why are simulation and analysis tools important for managing signal delay on PCBs?

Simulation and analysis tools allow designers to perform pre-layout and post-layout simulations, analyzing propagation delay, transmission delay, and signal integrity issues. These tools help identify potential problems early in the design process, enabling designers to make necessary adjustments before manufacturing.

Conclusion

Managing signal delay is a critical aspect of PCB design and manufacturing. By understanding the factors that contribute to propagation delay, transmission delay, and analog signal resonance, designers can make informed decisions to optimize signal integrity and ensure proper functionality of electronic devices. Employing strategies such as length matching, impedance control, and utilizing simulation and analysis tools can help mitigate the impact of signal delay and improve overall PCB performance.

No responses yet