Introduction to PCB Etching

PCB (Printed Circuit Board) etching is the process of removing unwanted copper from a PCB to create the desired circuit pattern. While it may seem like an interesting DIY project to attempt at home, there are several compelling reasons why we strongly advise against it. In this article, we will explore nine key reasons why PCB etching should be left to professionals in a properly equipped facility.

1. Health and Safety Risks

Exposure to Hazardous Chemicals

One of the primary concerns with home PCB etching is the use of dangerous chemicals. The etching process typically involves working with substances such as ferric chloride, ammonium persulfate, or hydrochloric acid. These chemicals can cause severe harm if not handled properly, including:

- Skin irritation and burns

- Eye damage

- Respiratory issues from inhaling fumes

- Digestive problems if ingested

Lack of Proper Safety Equipment

In a professional PCB manufacturing facility, employees are provided with appropriate personal protective equipment (PPE) such as:

| PPE Item | Purpose |

|---|---|

| Gloves | Protect hands from chemical exposure |

| Safety goggles | Prevent eye damage from splashes or fumes |

| Respirator | Filter out harmful vapors and particles |

| Protective clothing | Shield skin from contact with chemicals |

However, most hobbyists do not have access to this level of safety gear, putting them at greater risk of injury or illness.

2. Environmental Concerns

Improper Disposal of Chemicals

When etching PCBs at home, it is crucial to dispose of the used chemicals correctly. Pouring them down the drain or into the ground can lead to serious environmental contamination, harming wildlife and polluting water sources. Many of the chemicals used in PCB etching are classified as hazardous waste and require special disposal procedures that are not typically available to individuals.

Contribution to Electronic Waste

Attempting to etch PCBs at home often results in a higher failure rate due to the lack of precision equipment and controlled environment. This means that more boards may end up being discarded, contributing to the growing problem of electronic waste. Professional PCB manufacturers have optimized processes and quality control measures in place to minimize waste and ensure a higher success rate.

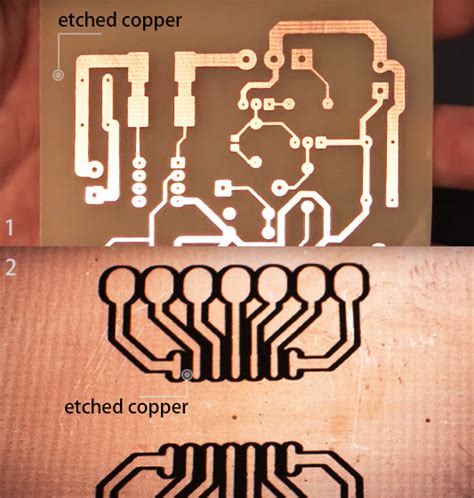

3. Inferior Quality Results

Lack of Precision Equipment

Creating high-quality PCBs requires specialized equipment that most hobbyists do not have access to. Professional PCB manufacturing facilities use advanced machines for:

- Precise copper etching

- Drill hole placement

- Solder mask application

- Silkscreen printing

Attempting to replicate these processes at home with makeshift tools often leads to subpar results, with issues such as:

- Uneven or incomplete etching

- Misaligned or poorly defined traces

- Inconsistent hole sizes

- Poor solder mask coverage

Inconsistent Etching Process

Achieving consistent results in PCB etching requires careful control over variables such as:

- Chemical concentration

- Temperature

- Agitation

- Etching time

Without proper monitoring and adjustment of these factors, the etching process can easily go awry, resulting in over-etched or under-etched boards that may not function as intended.

4. Limited Design Capabilities

Restricted Board Complexity

Home PCB etching techniques are generally limited to simple, single-layer designs. More complex boards with multiple layers, fine-pitch components, or high-density layouts are extremely difficult, if not impossible, to achieve with DIY methods. Professional PCB manufacturers have the tools and expertise to handle a wide range of design complexities, ensuring that your board meets your specific requirements.

Inability to Scale Production

If you need to produce multiple copies of your PCB, home etching quickly becomes impractical and time-consuming. Professional manufacturers can easily scale production to meet your needs, whether you require a few prototypes or a full production run. They also have the capacity to handle larger board sizes that may not be feasible to etch at home.

5. Time and Effort Required

Steep Learning Curve

Developing the skills and knowledge necessary to successfully etch PCBs at home can be a significant undertaking. You’ll need to research and experiment with different techniques, chemicals, and equipment, which can be a time-consuming and frustrating process. Even with practice, achieving consistent, high-quality results can be challenging for hobbyists.

Labor-Intensive Process

Etching PCBs at home is a labor-intensive process that requires careful attention to detail at every step. From designing the circuit and transferring the pattern to the copper board, to the actual etching and cleaning process, each stage demands a significant investment of time and effort. This can be particularly challenging if you need to produce multiple boards or iterate on your design.

6. Cost Considerations

Initial Investment in Equipment and Supplies

Setting up a home PCB etching workspace requires an initial investment in various tools, equipment, and supplies, such as:

- Etching tank or container

- Chemicals for etching and cleaning

- Personal protective equipment

- Copper-clad boards

- Resist material (e.g., photoresist, transfer paper)

- Exposure and developing equipment (for photoresist methods)

While some of these items may be relatively inexpensive, the costs can quickly add up, especially if you need to purchase higher-quality tools for better results.

Hidden Costs and Time Value

In addition to the direct costs of equipment and supplies, there are hidden costs associated with home PCB etching that should be considered. These include:

- Electricity and water consumption

- Proper disposal of hazardous waste

- Potential damage to household items or surfaces

- Time spent learning, experimenting, and troubleshooting

When you factor in the value of your time and effort, it may be more cost-effective to outsource your PCB fabrication to a professional manufacturer, especially for larger or more complex projects.

7. Legal and Regulatory Compliance

Potential Violation of Local Laws

Depending on where you live, etching PCBs at home may violate local laws or regulations related to the use and disposal of hazardous chemicals. Some areas have strict rules governing the handling and discharge of substances like ferric chloride or ammonium persulfate, and failure to comply can result in fines or legal consequences.

Zoning and Permit Requirements

In some cases, setting up a home PCB etching workspace may require special zoning permits or adherence to specific regulations, particularly if you plan to use the space for commercial purposes. Navigating these legal requirements can be complex and time-consuming, making it more practical to work with a professional manufacturer that already complies with all relevant laws and regulations.

8. Intellectual Property Risks

Potential Exposure of Sensitive Designs

When you etch PCBs at home, there is a risk that your sensitive or proprietary designs could be exposed to others, particularly if you need to seek assistance or advice from online communities or forums. Professional PCB manufacturers typically have strict confidentiality agreements and security measures in place to protect your intellectual property and ensure that your designs remain confidential.

Limited Protection for Your Work

If you develop a novel or innovative PCB design, etching it at home may limit your ability to protect your intellectual property. Professional manufacturers can work with you to establish proper legal safeguards, such as non-disclosure agreements or patents, to help secure your rights and prevent unauthorized copying or distribution of your work.

9. Lack of Professional Support

Limited Troubleshooting Resources

When issues arise during the home PCB etching process, you may have limited resources for troubleshooting and problem-solving. Professional PCB manufacturers have experienced engineers and technicians on staff who can help identify and resolve issues quickly, minimizing delays and ensuring that your boards meet your specifications.

No Warranty or Quality Guarantee

Unlike professional PCB manufacturers, who often offer warranties and quality guarantees for their work, etching boards at home means that you bear full responsibility for any defects or malfunctions. If a board fails or does not perform as expected, you will need to troubleshoot and rework the design on your own, which can be a frustrating and time-consuming process.

Frequently Asked Questions (FAQ)

1. Can I safely etch PCBs at home if I take proper precautions?

While it is possible to take safety precautions when etching PCBs at home, the risks associated with handling hazardous chemicals and the potential for environmental contamination still make it an inadvisable practice. It is always safer and more responsible to work with a professional PCB manufacturer.

2. Are there any alternative methods for home PCB fabrication that are safer and more environmentally friendly?

Some alternative methods for home PCB fabrication include using CNC routers or laser cutters to mill the copper traces, or using conductive ink pens to draw the circuits by hand. However, these methods still have limitations in terms of precision, complexity, and scalability compared to professional manufacturing processes.

3. How much does it typically cost to have a PCB professionally manufactured?

The cost of professional PCB manufacturing varies depending on factors such as the size and complexity of the board, the number of layers, the quantity ordered, and the turnaround time. Many manufacturers offer online quoting tools or have customer service representatives who can provide personalized quotes based on your specific requirements.

4. What should I look for when choosing a professional PCB manufacturer?

When selecting a professional PCB manufacturer, consider factors such as their experience and expertise, the range of services they offer, their quality control processes, their turnaround times, and their customer support. It’s also essential to choose a manufacturer that complies with relevant industry standards and certifications, such as ISO 9001, UL, or IPC.

5. Can I use a professional PCB manufacturer for prototyping and small-scale production?

Yes, many professional PCB manufacturers offer prototyping and small-scale production services, with some even specializing in low-volume, quick-turn fabrication. These services can be particularly valuable for testing and refining your designs before committing to a larger production run.

Conclusion

While etching PCBs at home may seem like an attractive option for hobbyists and DIY enthusiasts, the numerous risks and challenges associated with the process make it a practice that we strongly advise against. From the health and safety hazards of handling dangerous chemicals to the potential for environmental contamination and the limitations in design capabilities and quality control, home PCB etching simply cannot match the benefits of working with a professional manufacturer.

By entrusting your PCB fabrication to experienced professionals, you can ensure that your boards are produced to the highest standards of quality, reliability, and safety, while also saving time, effort, and potentially costly mistakes. As the electronics industry continues to evolve and innovate, partnering with a reputable PCB manufacturer is becoming increasingly essential for bringing your ideas to life and staying competitive in the market.

No responses yet