Introduction to PCB Colors

Printed Circuit Boards (PCBs) are an essential component of modern electronics. They provide a platform for mounting and connecting electronic components, allowing for the creation of complex circuits. One aspect of PCB design that is often overlooked is the color of the board. While the color of a PCB may seem like a purely aesthetic choice, it can actually have a significant impact on the functionality and reliability of the final product.

In this article, we will explore the seven main PCB colors and discuss how to select the best one for your project. We will cover the following topics:

- The role of solder mask in PCB color

- The seven main PCB colors

- Factors to consider when choosing a PCB color

- Frequently Asked Questions (FAQ) about PCB colors

The Role of Solder Mask in PCB Color

Before we dive into the specific colors available for PCBs, it’s important to understand the role of solder mask in determining the color of a board. Solder mask is a thin layer of polymer that is applied to the surface of a PCB to protect the copper traces from oxidation and to prevent solder from bridging between tracks during the soldering process.

Solder mask is available in a variety of colors, and the color of the solder mask is what determines the overall color of the PCB. The most common solder mask colors are green, red, blue, black, white, yellow, and purple.

The Seven Main PCB Colors

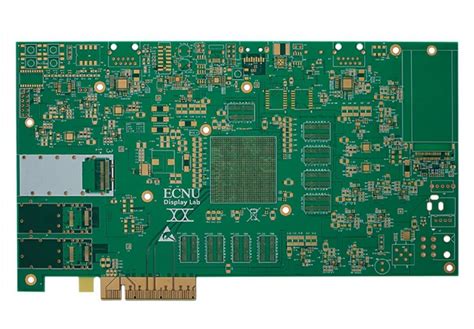

1. Green PCB

Green is the most common color for PCBs, and for good reason. Green solder mask provides excellent contrast against the white silkscreen, making it easy to read component labels and other markings on the board. Green PCBs are also less likely to show dirt and smudges than lighter-colored boards, making them a good choice for applications where the board may be handled frequently.

2. Red PCB

Red PCBs are less common than green boards, but they offer some unique advantages. Red solder mask provides excellent contrast against both white and black silkscreen, making it a good choice for boards with complex layouts or small component footprints. Red PCBs are also popular in certain industries, such as automotive and aerospace, where they are used to indicate high-voltage or safety-critical circuits.

3. Blue PCB

Blue PCBs are another popular choice, particularly in consumer electronics and computer hardware. Blue solder mask provides good contrast against white silkscreen, and the color is often associated with high-tech and advanced technology. Blue PCBs are also less likely to show fingerprints and smudges than lighter-colored boards.

4. Black PCB

Black PCBs are a popular choice for high-end electronics and audio equipment. Black solder mask provides a sleek and modern look, and it can help to hide surface imperfections and scratches. However, black PCBs can be more difficult to inspect and troubleshoot than lighter-colored boards, as the dark color can make it harder to see small components and traces.

5. White PCB

White PCBs are less common than other colors, but they offer some unique advantages. White solder mask provides excellent contrast against black silkscreen, making it easy to read component labels and other markings. White PCBs are also popular in certain industries, such as medical devices and scientific instruments, where cleanliness and sterility are important.

6. Yellow PCB

Yellow PCBs are relatively rare, but they can be useful in certain applications. Yellow solder mask provides good contrast against black silkscreen, and the bright color can help to make the board more visible in low-light conditions. Yellow PCBs are sometimes used in industrial control panels and other applications where visibility is important.

7. Purple PCB

Purple PCBs are the least common of the seven main colors, but they offer some unique advantages. Purple solder mask provides good contrast against white silkscreen, and the color is often associated with luxury and high-end products. Purple PCBs are sometimes used in consumer electronics and audio equipment, where they can help to differentiate a product from competitors.

Factors to Consider When Choosing a PCB Color

When selecting a color for your PCB, there are several factors to consider:

1. Contrast

The most important factor to consider when choosing a PCB color is contrast. The solder mask color should provide good contrast against the silkscreen color, making it easy to read component labels and other markings on the board. If the silkscreen is white, a darker solder mask color such as green, blue, or black may be best. If the silkscreen is black, a lighter solder mask color such as white or yellow may be more appropriate.

2. Application

The intended application of the PCB can also influence the choice of color. For example, red PCBs are often used in safety-critical applications, while white PCBs are popular in medical devices and other applications where cleanliness is important. Consider the specific requirements and preferences of your industry when selecting a PCB color.

3. Aesthetics

While functionality should always be the top priority, aesthetics can also play a role in PCB color selection. Some colors, such as black and purple, are often associated with high-end and luxury products, while others, such as blue and green, are more neutral and versatile. Consider the overall look and feel of your product when choosing a PCB color.

4. Cost

The cost of different PCB colors can vary depending on the manufacturer and the specific solder mask material used. In general, green and red PCBs tend to be the most affordable, while more exotic colors like purple and yellow may be more expensive. Consider your budget when selecting a PCB color, and weigh the potential benefits against the added cost.

FAQ

1. Does PCB color affect functionality?

In most cases, the color of a PCB does not directly affect its functionality. However, the color of the solder mask can impact the ability to inspect and troubleshoot the board, as well as the visibility of component labels and other markings.

2. Can I mix and match PCB colors in a single project?

Yes, it is possible to use different PCB colors within a single project. However, it is important to consider the impact on manufacturing and assembly, as well as the potential for confusion during the troubleshooting and repair process.

3. Are there any industry standards for PCB colors?

There are no universal industry standards for PCB colors, but certain industries may have specific color preferences or requirements. For example, red PCBs are often used in safety-critical applications, while white PCBs are popular in medical devices.

4. How do I specify the PCB color when ordering from a manufacturer?

When ordering PCBs from a manufacturer, you will typically need to specify the desired solder mask color as part of your design files. Most manufacturers will provide a list of available colors and their associated codes or names.

5. Can I change the color of an existing PCB?

In most cases, it is not practical or cost-effective to change the color of an existing PCB. The solder mask is applied during the manufacturing process, and changing the color would require stripping off the existing mask and applying a new one, which could damage the board or components.

Conclusion

Choosing the right color for your PCB is an important consideration in the design process. While the color of a PCB does not directly affect its functionality, it can impact the ability to inspect and troubleshoot the board, as well as the overall aesthetics of the final product.

When selecting a PCB color, consider factors such as contrast, application, aesthetics, and cost. The seven main PCB colors – green, red, blue, black, white, yellow, and purple – each offer unique advantages and disadvantages, and the best choice will depend on the specific requirements of your project.

By understanding the role of solder mask in PCB color and the factors to consider when making a selection, you can ensure that your PCB not only functions properly but also looks great and meets the needs of your intended application.

| PCB Color | Advantages | Disadvantages |

|---|---|---|

| Green | Excellent contrast against white silkscreen, hides dirt | May not stand out in certain applications |

| Red | Excellent contrast against white and black silkscreen | May be more expensive than other colors |

| Blue | Good contrast against white silkscreen, high-tech look | May show fingerprints and smudges more than darker colors |

| Black | Sleek and modern look, hides surface imperfections | Can be difficult to inspect and troubleshoot |

| White | Excellent contrast against black silkscreen, clean look | May show dirt and smudges more than darker colors |

| Yellow | Good contrast against black silkscreen, high visibility | Relatively rare, may be more expensive |

| Purple | Good contrast against white silkscreen, luxury look | Least common color, may be more expensive |

No responses yet