Introduction to PCB Ordering

Printed Circuit Boards (PCBs) are the backbone of modern electronics. They are used in almost every electronic device, from smartphones and computers to medical equipment and aerospace systems. PCBs provide a way to mechanically support and electrically connect electronic components using conductive pathways, tracks, or signal traces etched from copper sheets laminated onto a non-conductive substrate.

With the advancement of technology and the increasing demand for custom electronics, PCB ordering has become more accessible than ever before. Online PCB ordering services have made it possible for individuals and businesses to order custom PCBs without the need for expensive equipment or extensive knowledge of PCB manufacturing.

In this article, we will explore five ways to order custom PCBs online, including the benefits and drawbacks of each method. We will also provide tips on how to choose the right PCB manufacturer and ensure that your PCB design is ready for production.

The Benefits of Online PCB Ordering

Before we dive into the different ways to order custom PCBs online, let’s first discuss the benefits of online PCB ordering.

1. Cost-effective

Online PCB ordering is often more cost-effective than traditional PCB manufacturing methods. Online PCB manufacturers have streamlined their processes and can offer competitive prices due to their high volume of orders. This means that even small businesses and individuals can afford to order custom PCBs without breaking the bank.

2. Fast turnaround time

Online PCB ordering also offers fast turnaround times. Many online PCB manufacturers can produce and ship PCBs within a few days, depending on the complexity of the design and the quantity ordered. This is a significant advantage over traditional PCB manufacturing methods, which can take weeks or even months to complete.

3. Access to a wide range of PCB options

Online PCB ordering services offer a wide range of PCB options, including different materials, thicknesses, copper weights, and surface finishes. This allows customers to choose the best options for their specific application and budget.

4. Easy to use

Online PCB ordering is easy to use, even for those with limited technical knowledge. Most online PCB manufacturers provide user-friendly interfaces that guide customers through the ordering process step-by-step. Customers can upload their PCB design files, select their desired options, and receive a quote within minutes.

5. Quality control

Online PCB manufacturers use advanced quality control processes to ensure that each PCB meets the highest standards of quality. This includes automated optical inspection (AOI), manual visual inspection, and electrical testing. Customers can be confident that their PCBs will function as intended and meet their specific requirements.

5 Ways to Order Custom PCBs Online

Now that we’ve discussed the benefits of online PCB ordering, let’s explore five ways to order custom PCBs online.

1. PCB Prototype Services

PCB prototype services are designed for customers who need a small quantity of PCBs for testing and evaluation purposes. These services typically offer fast turnaround times and low minimum order quantities (MOQs), making them ideal for individuals and small businesses.

Some popular PCB prototype services include:

- OSH Park

- PCBWay

- Seeed Studio

- DirtyPCBs

To order PCBs through a prototype service, customers typically need to upload their PCB design files in Gerber format, select their desired options (such as material, thickness, and quantity), and pay for their order. The PCBs are then manufactured and shipped to the customer within a few days.

| Service | Min. Quantity | Lead Time | Price (10 pcs, 2 layer, 100x100mm) |

|---|---|---|---|

| OSH Park | 3 | 7-10 days | $15 |

| PCBWay | 5 | 3-5 days | $12 |

| Seeed Studio | 5 | 5-7 days | $20 |

| DirtyPCBs | 10 | 12-19 days | $14 |

2. Full-Service PCB Manufacturers

Full-service PCB manufacturers offer a wide range of PCB manufacturing services, including design, prototyping, assembly, and testing. These manufacturers typically have higher MOQs and longer lead times than prototype services, but they offer more customization options and can handle larger production runs.

Some popular full-service PCB manufacturers include:

- Advanced Circuits

- Sierra Circuits

- Sunstone Circuits

- Royal Circuits

To order PCBs through a full-service manufacturer, customers typically need to provide their PCB design files and specifications, and work with the manufacturer’s sales and engineering teams to finalize the details of their order. The PCBs are then manufactured, assembled (if required), and shipped to the customer.

| Manufacturer | Min. Quantity | Lead Time | Price (100 pcs, 4 layer, 100x100mm) |

|---|---|---|---|

| Advanced Circuits | 1 | 5-7 days | $600 |

| Sierra Circuits | 1 | 5-10 days | $700 |

| Sunstone Circuits | 1 | 5-7 days | $800 |

| Royal Circuits | 1 | 7-10 days | $550 |

3. PCB Marketplaces

PCB marketplaces are online platforms that connect customers with multiple PCB manufacturers. These marketplaces allow customers to compare prices and lead times from different manufacturers, and place orders through a single interface.

Some popular PCB marketplaces include:

- PCBShopper

- PCBCart

- PCBUniverse

- NextPCB

To order PCBs through a marketplace, customers typically need to upload their PCB design files, select their desired options, and compare prices and lead times from different manufacturers. Once they have selected a manufacturer, they can place their order and pay through the marketplace.

| Marketplace | Manufacturers | Min. Quantity | Lead Time |

|---|---|---|---|

| PCBShopper | 18 | 5 | 3-7 days |

| PCBCart | 10 | 1 | 4-7 days |

| PCBUniverse | 12 | 5 | 4-8 days |

| NextPCB | 8 | 5 | 5-10 days |

4. Design and Manufacturing Services

Design and manufacturing services are ideal for customers who need help with PCB design and layout, as well as manufacturing. These services typically offer a range of design tools and resources, as well as expert support from experienced engineers.

Some popular design and manufacturing services include:

- Altium Designer

- Autodesk Eagle

- KiCad

- Upverter

To use a design and manufacturing service, customers typically need to create an account, access the service’s design tools and resources, and work with the service’s engineers to finalize their PCB design. Once the design is complete, customers can place an order for manufacturing and assembly through the service.

| Service | Design Tools | Manufacturing | Price |

|---|---|---|---|

| Altium Designer | Altium Designer | Yes | $6,000/year |

| Autodesk Eagle | Autodesk Eagle | Yes | $100/month |

| KiCad | KiCad | No | Free |

| Upverter | Upverter | Yes | $1,000/year |

5. Turnkey PCB Assembly Services

Turnkey PCB assembly services are ideal for customers who need complete PCB assembly, including component sourcing and testing. These services handle the entire PCB production process, from design to final assembly and testing.

Some popular turnkey PCB assembly services include:

- MacroFab

- Screaming Circuits

- CircuitHub

- PCBCart

To use a turnkey PCB assembly service, customers typically need to provide their PCB design files and bill of materials (BOM), and work with the service’s engineers to finalize the details of their order. The service then handles the entire production process, including component sourcing, PCB manufacturing, assembly, and testing. The finished PCBs are then shipped to the customer.

| Service | Min. Quantity | Lead Time | Price |

|---|---|---|---|

| MacroFab | 1 | 10-15 days | $500 |

| Screaming Circuits | 1 | 5-10 days | $600 |

| CircuitHub | 1 | 7-14 days | $700 |

| PCBCart | 1 | 8-12 days | $400 |

How to Choose the Right PCB Manufacturer

Now that we’ve explored the different ways to order custom PCBs online, let’s discuss how to choose the right PCB manufacturer for your project.

1. Consider your project requirements

The first step in choosing a PCB manufacturer is to consider your project requirements. This includes factors such as:

- PCB size and complexity

- Material and thickness

- Copper weight and trace width

- Surface finish

- Quantity and lead time

- Budget

Once you have a clear understanding of your project requirements, you can start researching PCB manufacturers that can meet those requirements.

2. Check for certifications and quality standards

When choosing a PCB manufacturer, it’s important to check for certifications and quality standards. Some common certifications and standards to look for include:

- ISO 9001 (quality management)

- UL (safety)

- RoHS (restriction of hazardous substances)

- IPC (industry standards for PCB manufacturing and assembly)

Manufacturers that hold these certifications and adhere to these standards are more likely to produce high-quality PCBs that meet your requirements.

3. Read reviews and ask for references

Another way to evaluate PCB manufacturers is to read reviews and ask for references. Look for reviews from other customers who have used the manufacturer’s services, and pay attention to feedback on factors such as quality, communication, and customer service.

You can also ask the manufacturer for references from previous customers, and reach out to those customers to ask about their experience working with the manufacturer.

4. Consider the manufacturer’s capabilities and expertise

When choosing a PCB manufacturer, it’s important to consider their capabilities and expertise. Some manufacturers specialize in certain types of PCBs or industries, while others offer a wide range of services.

Look for manufacturers that have experience with the specific type of PCB you need, and that have the equipment and expertise to handle your project requirements. You may also want to consider manufacturers that offer value-added services such as design support, component sourcing, and testing.

5. Communicate clearly and provide detailed specifications

Finally, when working with a PCB manufacturer, it’s important to communicate clearly and provide detailed specifications. This includes providing accurate PCB design files, bill of materials, and any special requirements or instructions.

Clear communication can help ensure that your PCBs are manufactured to your exact specifications, and can help avoid costly mistakes or delays.

Tips for Preparing Your PCB Design for Production

Before you order custom PCBs online, it’s important to ensure that your PCB design is ready for production. Here are some tips to help you prepare your PCB design:

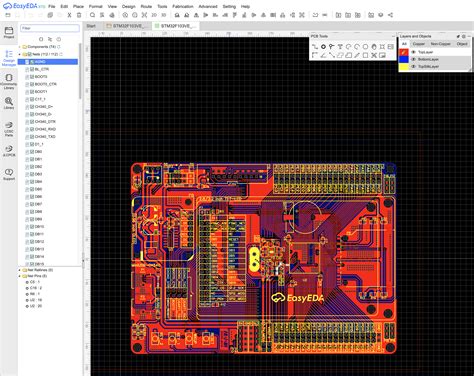

1. Use a reputable PCB design software

There are many PCB design software options available, ranging from free open-source tools to expensive commercial software. When choosing a PCB design software, look for one that is widely used in the industry and that has a good reputation for reliability and accuracy.

Some popular PCB design software options include:

- Altium Designer

- Autodesk Eagle

- KiCad

- OrCAD

- Cadence Allegro

2. Follow PCB design guidelines and best practices

To ensure that your PCB design is manufacturable and reliable, it’s important to follow PCB design guidelines and best practices. Some key guidelines to follow include:

- Ensuring adequate clearance between components and traces

- Using appropriate trace widths and spacing for your PCB’s electrical requirements

- Placing components and traces to minimize EMI and crosstalk

- Using appropriate via sizes and spacing

- Including appropriate silkscreen and solder mask layers

Many PCB design software tools include built-in design rule checks (DRCs) that can help you identify and fix design issues before sending your files for manufacturing.

3. Create accurate and complete PCB design files

When ordering custom PCBs online, you’ll need to provide your PCB design files in a format that the manufacturer can use. The most common file format for PCB manufacturing is Gerber, which is a standard file format used by PCB fabrication houses.

To create accurate and complete Gerber files, you’ll need to export your PCB design from your PCB design software. Make sure to include all necessary layers, including copper, solder mask, silkscreen, and drill files. You may also need to include additional files such as a bill of materials (BOM) and assembly drawings.

4. Double-check your design before ordering

Before sending your PCB design files to a manufacturer, it’s important to double-check your design for accuracy and completeness. This includes:

- Checking for design rule violations and fixing any issues

- Verifying that all components and traces are correctly placed and connected

- Ensuring that your design files include all necessary layers and files

- Checking that your design meets your project requirements and specifications

Taking the time to double-check your design can help avoid costly mistakes and delays in the manufacturing process.

Frequently Asked Questions (FAQ)

What is the minimum order quantity for custom PCBs?

The minimum order quantity (MOQ) for custom PCBs varies depending on the manufacturer and the specific service you choose. Some PCB prototype services have MOQs as low as 5 or 10 pieces, while full-service manufacturers may have MOQs of 100 pieces or more.

How long does it take to receive custom PCBs after placing an order?

The lead time for custom PCBs also varies depending on the manufacturer and the service you choose. PCB prototype services typically have lead times of 3-10 days, while full-service manufacturers may have lead times of 2-3 weeks or more.

What is the typical cost for custom PCBs?

The cost for custom PCBs depends on a variety of factors, including the size and complexity of the PCB, the material and thickness, the copper weight and trace width, the surface finish, and the quantity ordered. Prices can range from a few dollars per PCB for simple prototype boards to hundreds or thousands of dollars for complex, high-volume production runs.

What file formats are required for PCB manufacturing?

The most common file format for PCB manufacturing is Gerber, which is a standard file format used by PCB fabrication houses. Gerber files include copper, solder mask, silkscreen, and drill layers. Some manufacturers may also require additional files such as a bill of materials (BOM) and assembly drawings.

Can I order assembled PCBs online?

Yes, many online PCB manufacturers offer assembly services in addition to PCB fabrication. Turnkey PCB assembly services handle the entire production process, from component sourcing and PCB manufacturing to assembly and testing. Some services also offer design support and value-added services such as component sourcing and testing.

Conclusion

Ordering custom PCBs online has never been easier or more accessible. With a wide range of services and options available, from PCB prototype services to full-service manufacturers and turnkey assembly services, there’s a solution for every project and budget.

By understanding the different ways to order custom PCBs online, and by following best practices for PCB design and manufacturability, you can ensure that your custom PCBs are high-quality, reliable, and delivered on time and on budget.

Whether you’re a hobbyist working on a personal project or an engineer designing a complex system for a large corporation, online PCB ordering services provide a convenient and cost-effective way to bring your electronic designs to life.

No responses yet