Introduction to the 28BYJ-48 Unipolar Stepper Motor

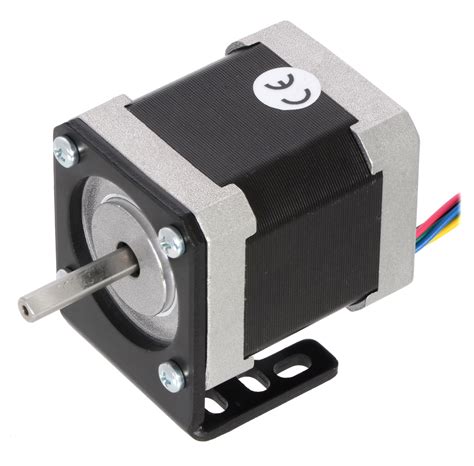

The 28BYJ-48 is a popular and affordable 5-wire, 5V unipolar stepper motor widely used in various DIY projects, robotics, and automation applications. This compact and reliable motor offers precise positioning and control, making it an excellent choice for beginners and experienced makers alike.

What is a Unipolar Stepper Motor?

A unipolar stepper motor is a type of stepper motor that has a single winding per phase, with a center tap. This center tap allows the current to flow in either direction through the winding, enabling the motor to step in both clockwise and counterclockwise directions. Unipolar stepper motors are known for their simplicity and ease of control compared to bipolar stepper motors.

Specifications and Features of the 28BYJ-48

The 28BYJ-48 unipolar stepper motor comes with the following specifications and features:

| Specification | Value |

|---|---|

| Rated Voltage | 5V DC |

| Number of Phases | 4 |

| Step Angle | 5.625°/64 |

| Steps per Revolution | 64 |

| Frequency | 100 Hz |

| DC Resistance | 50Ω±7% (25°C) |

| Idle In-traction Frequency | > 600 Hz |

| Idle Out-traction Frequency | > 1000 Hz |

| In-traction Torque | >34.3 mN.m (120 Hz) |

| Self-positioning Torque | >34.3 mN.m |

| Friction Torque | 600-1200 gf.cm |

| Pull-in Torque | 300 gf.cm |

| Insulation Resistance | >10 MΩ (500V) |

| Insulation Strength | 600 VAC/1 mA/1 s |

| Rise in Temperature | <40 K (120 Hz) |

| Noise | <35 dB (120 Hz, No Load, 10 cm) |

Advantages of the 28BYJ-48

- Low cost

- Compact size

- Precise positioning

- Easy to control

- Compatible with various drivers and microcontrollers

Wiring and Connecting the 28BYJ-48

The 28BYJ-48 unipolar stepper motor has five wires:

- Red: 5V power supply

- Orange: Coil 1

- Yellow: Coil 2

- Pink: Coil 3

- Blue: Coil 4

To connect the motor to a microcontroller, such as an Arduino, you’ll need a suitable driver board. The most common driver for the 28BYJ-48 is the ULN2003 driver board, which has a built-in Darlington transistor array to handle the current requirements of the motor.

Connecting the 28BYJ-48 to an Arduino using a ULN2003 Driver Board

- Connect the red wire to the 5V pin on the Arduino.

- Connect the orange, yellow, pink, and blue wires to the IN1, IN2, IN3, and IN4 pins on the ULN2003 driver board, respectively.

- Connect the GND pin on the ULN2003 driver board to the GND pin on the Arduino.

- Connect the IN1, IN2, IN3, and IN4 pins on the ULN2003 driver board to digital pins on the Arduino (e.g., pins 8, 9, 10, and 11).

Controlling the 28BYJ-48 with Arduino

To control the 28BYJ-48 unipolar stepper motor with an Arduino, you’ll need to use a suitable library, such as the AccelStepper library or the Stepper library. These libraries provide functions to set the speed, acceleration, and target position of the motor, as well as to move the motor a specified number of steps.

Example Code using the AccelStepper Library

#include <AccelStepper.h>

#define IN1 8

#define IN2 9

#define IN3 10

#define IN4 11

AccelStepper stepper(AccelStepper::HALF4WIRE, IN1, IN3, IN2, IN4);

void setup() {

stepper.setMaxSpeed(1000);

stepper.setAcceleration(500);

}

void loop() {

if (stepper.distanceToGo() == 0) {

stepper.moveTo(-stepper.currentPosition());

}

stepper.run();

}

This example code moves the 28BYJ-48 stepper motor back and forth continuously, using half-step mode for smoother motion.

Applications of the 28BYJ-48 Unipolar Stepper Motor

The 28BYJ-48 unipolar stepper motor is suitable for a wide range of applications, including:

- Robotics: The motor can be used to create small robots, such as drawing robots or simple robotic arms.

- Automation: The 28BYJ-48 can be used in automated systems for precise positioning and control, such as in 3D printers or CNC machines.

- Home automation: The motor can be used in DIY smart home projects, such as automated blinds or door locks.

- Camera gimbals: The 28BYJ-48 can be used to create small camera gimbals for stabilizing footage.

- Clocks and timers: The precise stepping of the motor makes it suitable for creating unique clocks or timers.

Troubleshooting and Maintenance

Common Issues and Solutions

- Motor not turning:

- Check the wiring connections and ensure they are secure.

- Verify that the power supply is providing the correct voltage (5V).

-

Make sure the code is uploaded correctly and the pins are defined properly.

-

Motor skipping steps or losing position:

- Reduce the speed or acceleration settings in the code.

- Ensure the motor is not overloaded or obstructed.

-

Check the power supply and ensure it can provide sufficient current for the motor.

-

Motor making unusual noises:

- Verify that the motor is properly mounted and not touching any other components.

- Check for any loose or damaged gears.

- Ensure the motor is not being driven beyond its specifications.

Maintenance Tips

- Keep the motor clean and free from dust and debris.

- Regularly inspect the wiring and connections for any signs of wear or damage.

- Avoid overloading the motor or driving it beyond its specified limits.

- Store the motor in a dry, cool place when not in use.

FAQ

-

Q: Can I use the 28BYJ-48 stepper motor with a 12V power supply?

A: No, the 28BYJ-48 is designed to operate at 5V. Using a higher voltage may damage the motor and the driver board. -

Q: How do I increase the torque of the 28BYJ-48 stepper motor?

A: To increase the torque, you can try using a higher current driver board, such as the ULN2003A. However, keep in mind that the motor’s specifications limit the maximum torque it can produce. -

Q: Can I use the 28BYJ-48 stepper motor without a driver board?

A: While it is possible to control the motor directly from a microcontroller, it is not recommended, as the microcontroller may not be able to provide sufficient current to drive the motor. Using a dedicated driver board, such as the ULN2003, is the preferred method. -

Q: How precise is the 28BYJ-48 stepper motor?

A: The 28BYJ-48 has a step angle of 5.625°/64, which means it takes 64 steps to complete one full revolution. This allows for precise positioning and control, suitable for most DIY projects and applications. -

Q: Can I use the 28BYJ-48 stepper motor for continuous rotation?

A: Yes, the 28BYJ-48 can be used for continuous rotation by setting the target position to a large value or using a library that supports continuous rotation, such as the AccelStepper library with therunSpeed()function.

Conclusion

The 28BYJ-48 unipolar stepper motor is a versatile and affordable choice for a wide range of DIY projects and applications. Its compact size, precise positioning, and ease of control make it an excellent option for beginners and experienced makers alike. By understanding the motor’s specifications, wiring, and control methods, you can successfully integrate the 28BYJ-48 into your projects and create innovative solutions in robotics, automation, and beyond.

No responses yet