Introduction to PCB Sourcing from China

China has become a global hub for electronic component manufacturing, including printed circuit boards (PCBs). The country’s vast manufacturing capabilities, competitive pricing, and skilled workforce have made it an attractive destination for businesses looking to source high-quality PCBs. In this article, we will explore 16 compelling reasons why you should consider buying circuit boards from China.

1. Cost-Effective Manufacturing

One of the primary reasons to source PCBs from China is the significant cost savings. Chinese manufacturers offer highly competitive prices due to several factors, including:

- Lower labor costs

- Government subsidies and incentives

- Economies of scale

- Efficient supply chain management

These factors enable Chinese PCB manufacturers to produce high-quality boards at prices that are often much lower than those offered by manufacturers in other countries.

2. Extensive Manufacturing Capabilities

China’s PCB manufacturing industry is well-established and has a wide range of capabilities. Chinese manufacturers can produce various types of PCBs, including:

- Single-sided PCBs

- Double-sided PCBs

- Multi-layer PCBs

- Flexible PCBs

- Rigid-flex PCBs

- High-density interconnect (HDI) PCBs

This extensive range of manufacturing capabilities allows businesses to source PCBs that meet their specific requirements, regardless of the complexity or scale of their projects.

3. Skilled and Experienced Workforce

China has a large pool of skilled and experienced workers in the PCB manufacturing industry. Many Chinese engineers and technicians have years of experience in designing and producing PCBs, ensuring high-quality products and efficient production processes.

Additionally, Chinese universities and vocational schools have been focusing on electronics and manufacturing education, continuously supplying the industry with well-trained professionals.

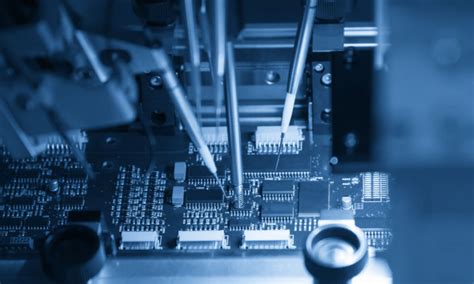

4. Advanced Technology and Equipment

Chinese PCB manufacturers have invested heavily in state-of-the-art technology and equipment to stay competitive in the global market. Many factories are equipped with the latest automated production lines, inspection systems, and testing equipment, ensuring consistent quality and efficient production.

Some of the advanced technologies used in Chinese PCB manufacturing include:

- Surface mount technology (SMT)

- Ball grid array (BGA) technology

- Microvia technology

- Embedded component technology

These technologies enable Chinese manufacturers to produce high-quality, complex PCBs that meet the demanding requirements of modern electronics.

5. Rapid Prototyping and Short Lead Times

Chinese PCB manufacturers are known for their ability to provide rapid prototyping services and short lead times. Many factories offer quick-turn prototyping, allowing businesses to test and refine their designs before committing to full-scale production.

Moreover, the efficient supply chain and logistics infrastructure in China enable manufacturers to deliver finished products quickly, reducing overall lead times and helping businesses bring their products to market faster.

6. Flexibility and Customization

Chinese PCB manufacturers are highly flexible and can accommodate a wide range of customization requirements. Whether you need specific materials, unique board shapes, or special features, Chinese factories can often tailor their production processes to meet your needs.

This flexibility allows businesses to create custom PCBs that are optimized for their specific applications, improving product performance and competitiveness.

7. Stringent Quality Control

Despite the perception of lower quality associated with Chinese manufacturing, many Chinese PCB manufacturers adhere to stringent quality control standards. Leading factories have implemented rigorous quality management systems, such as ISO 9001 and IATF 16949, to ensure consistent product quality.

Additionally, Chinese manufacturers often employ advanced inspection and testing equipment, such as automated optical inspection (AOI) and in-circuit testing (ICT), to identify and correct any defects or issues during the production process.

8. Environmental Compliance

As environmental regulations become increasingly stringent worldwide, Chinese PCB manufacturers have taken steps to ensure compliance with international standards, such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals).

Many Chinese factories have invested in eco-friendly production processes and materials, such as lead-free soldering and Halogen-free PCBs, to minimize their environmental impact and meet the requirements of environmentally conscious customers.

9. Robust Supply Chain

China has a well-established and robust supply chain for PCB manufacturing. The country is home to numerous suppliers of raw materials, components, and equipment, ensuring a stable and reliable supply of resources for PCB production.

This robust supply chain helps Chinese manufacturers maintain consistent quality, competitive pricing, and timely delivery, even during periods of high demand or market fluctuations.

10. Industry Clusters and Specialization

China has developed several industry clusters that specialize in PCB manufacturing, such as Shenzhen, Guangzhou, and Suzhou. These clusters bring together a concentration of PCB manufacturers, suppliers, and supporting industries, fostering collaboration, innovation, and efficiency.

The specialization within these clusters allows businesses to find manufacturers with expertise in specific types of PCBs or industries, such as automotive, medical, or aerospace, ensuring that their specific requirements are met.

11. Intellectual Property Protection

While intellectual property (IP) protection has been a concern for some businesses when sourcing from China, the country has made significant progress in recent years to strengthen its IP laws and enforcement.

Many Chinese PCB manufacturers have implemented strict confidentiality agreements and secure data management systems to protect their clients’ intellectual property. Additionally, businesses can take proactive measures, such as filing for patents and trademarks in China, to safeguard their IP rights.

12. Established Logistics and Shipping Networks

China has a well-developed logistics and shipping infrastructure, with numerous ports, airports, and freight forwarders that facilitate the efficient transportation of goods worldwide.

This established network allows businesses to easily import PCBs from China and distribute them to their target markets, reducing shipping times and costs.

13. Support for Small and Large Volume Orders

Chinese PCB manufacturers cater to a wide range of order volumes, from small prototype runs to large-scale production. This flexibility enables businesses of all sizes, from startups to multinational corporations, to source PCBs from China that meet their specific needs and budget constraints.

Many Chinese factories also offer volume discounts, making it more cost-effective for businesses to scale up their production as their demand grows.

14. Continuous Improvement and Innovation

The Chinese PCB manufacturing industry is constantly evolving, with manufacturers investing in research and development to improve their processes, materials, and technologies.

This focus on continuous improvement and innovation ensures that businesses sourcing PCBs from China have access to the latest advancements in the field, enabling them to create more advanced, reliable, and cost-effective products.

15. Comprehensive Service Offerings

Many Chinese PCB manufacturers offer a comprehensive range of services beyond just manufacturing. These services may include:

- PCB design and layout

- Component sourcing and procurement

- Assembly and testing

- Packaging and labeling

- Logistics and shipping

By providing these additional services, Chinese manufacturers can serve as a one-stop-shop for businesses, streamlining their supply chain and reducing the need for multiple vendors.

16. Long-Term Partnerships and Reliability

Establishing long-term partnerships with reliable Chinese PCB manufacturers can provide businesses with a stable and dependable supply of high-quality PCBs.

Many Chinese factories are eager to build lasting relationships with their clients, offering personalized service, technical support, and continuous improvement to meet their evolving needs. By fostering these partnerships, businesses can ensure a consistent supply of PCBs that meet their quality, cost, and delivery requirements.

Frequently Asked Questions (FAQ)

1. How can I ensure the quality of PCBs sourced from China?

To ensure the quality of PCBs sourced from China, consider the following:

- Choose manufacturers with ISO 9001 or IATF 16949 certification

- Request samples and conduct thorough testing

- Verify the manufacturer’s quality control processes and equipment

- Establish clear quality expectations and communication channels

2. Are Chinese PCB manufacturers capable of producing complex, high-density boards?

Yes, many Chinese PCB manufacturers have the technology and expertise to produce complex, high-density boards, such as HDI PCBs and multi-layer boards. However, it is essential to carefully evaluate the capabilities of potential manufacturers and choose one that specializes in the type of PCB you require.

3. How can I protect my intellectual property when sourcing PCBs from China?

To protect your intellectual property when sourcing PCBs from China, consider the following measures:

- Sign non-disclosure agreements (NDAs) with your chosen manufacturer

- File for patents and trademarks in China

- Implement secure data management and communication systems

- Conduct due diligence on potential manufacturers to assess their IP protection practices

4. What is the typical lead time for PCBs sourced from China?

Lead times for PCBs sourced from China can vary depending on factors such as the complexity of the board, order volume, and manufacturer’s capacity. Typical lead times range from 1-2 weeks for prototype orders to 4-8 weeks for larger production runs. However, many Chinese manufacturers offer expedited services for urgent orders.

5. How can I manage communication and cultural differences when working with Chinese PCB manufacturers?

To effectively manage communication and cultural differences when working with Chinese PCB manufacturers:

- Establish clear and detailed communication channels, such as regular video conferences or designated point of contact

- Use simple, concise language and visual aids to convey your requirements

- Be aware of cultural differences in business practices, such as hierarchy, decision-making processes, and communication styles

- Consider hiring a local representative or sourcing agent to bridge any language or cultural gaps

Conclusion

Buying circuit boards from China offers numerous advantages for businesses looking to optimize their PCB sourcing strategy. From cost-effective manufacturing and extensive capabilities to flexible customization and robust supply chains, Chinese PCB manufacturers provide a compelling value proposition.

By carefully evaluating potential manufacturers, establishing clear quality and communication standards, and fostering long-term partnerships, businesses can leverage the strengths of the Chinese PCB manufacturing industry to create high-quality, competitive products.

As the global electronics industry continues to evolve, China’s PCB manufacturing sector is well-positioned to remain a key player, offering businesses a reliable and efficient source of circuit boards for years to come.

| Advantages of Sourcing PCBs from China | Description |

|---|---|

| Cost-Effective Manufacturing | Lower labor costs, government subsidies, and economies of scale enable competitive pricing |

| Extensive Manufacturing Capabilities | Wide range of PCB types and technologies, including single-sided, double-sided, multi-layer, flexible, rigid-flex, and HDI boards |

| Skilled and Experienced Workforce | Large pool of engineers and technicians with expertise in PCB design and production |

| Advanced Technology and Equipment | State-of-the-art automated production lines, inspection systems, and testing equipment ensure consistent quality and efficiency |

| Rapid Prototyping and Short Lead Times | Quick-turn prototyping services and efficient supply chain enable faster time-to-market |

By leveraging these advantages and carefully managing the sourcing process, businesses can unlock the full potential of buying circuit boards from China, ensuring a reliable supply of high-quality PCBs that meet their specific requirements and help them stay competitive in the global market.

No responses yet