1. Enhanced Efficiency and Productivity

IoT-EMS“>IoT-EMS integration enables real-time monitoring and control of manufacturing processes, leading to improved efficiency and productivity. By connecting machines, sensors, and devices, EMS manufacturers can optimize their operations, reduce downtime, and increase output.

Real-time Data Collection and Analysis

IoT devices and sensors collect real-time data from various points in the manufacturing process, allowing EMS companies to monitor and analyze performance metrics. This data-driven approach helps identify bottlenecks, inefficiencies, and areas for improvement, enabling proactive decision-making and process optimization.

Predictive Maintenance

IoT-enabled predictive maintenance helps EMS manufacturers anticipate and prevent equipment failures before they occur. By monitoring machine health and performance data, IoT systems can detect anomalies and trigger maintenance alerts, minimizing unplanned downtime and maximizing equipment availability.

2. Improved Quality Control

IoT-EMS integration enhances quality control processes, ensuring consistent and high-quality products. By leveraging IoT technologies, EMS manufacturers can monitor and control critical parameters throughout the manufacturing process, reducing defects and improving overall product quality.

Real-time Quality Monitoring

IoT sensors can monitor various quality parameters, such as temperature, humidity, vibration, and pressure, in real-time. This enables EMS manufacturers to detect deviations from set standards and take immediate corrective actions, preventing quality issues from propagating through the production line.

Automated Inspection and Testing

IoT-enabled automated inspection and testing systems can perform high-speed, high-precision quality checks, reducing the need for manual intervention. These systems can identify defects, measure dimensions, and verify functionality, ensuring that only products meeting the required specifications are released for further processing or shipment.

3. Inventory Management and Supply Chain Optimization

IoT-EMS integration streamlines inventory management and optimizes supply chain operations. By leveraging IoT technologies, EMS manufacturers can gain real-time visibility into inventory levels, track materials and components, and ensure timely replenishment.

Real-time Inventory Tracking

IoT-enabled inventory tracking systems can provide real-time information on stock levels, location, and movement of materials and components. This visibility helps EMS manufacturers optimize inventory levels, reduce stockouts, and minimize excess inventory, leading to improved operational efficiency and cost savings.

Supply Chain Transparency

IoT technologies enable end-to-end supply chain transparency, allowing EMS manufacturers to track materials and components from suppliers to the final product. This transparency helps identify potential supply chain disruptions, enables proactive risk mitigation, and facilitates collaboration with suppliers for timely deliveries and quality assurance.

4. Customization and Flexibility

IoT-EMS integration enables EMS manufacturers to offer customized solutions and adapt to changing customer requirements. By leveraging IoT technologies, EMS companies can implement flexible manufacturing processes, allowing for quick product customization and shorter lead times.

Flexible Manufacturing Systems

IoT-enabled flexible manufacturing systems can quickly adapt to changes in product designs, volumes, and configurations. By reconfiguring machines and processes based on real-time data and customer requirements, EMS manufacturers can efficiently handle small batches, personalized products, and frequent design changes.

Mass Customization

IoT technologies enable EMS manufacturers to offer mass customization, combining the efficiency of mass production with the flexibility of customization. By collecting and analyzing customer preferences and requirements through IoT-enabled systems, EMS companies can tailor products to individual needs while maintaining economies of scale.

5. Energy Efficiency and Sustainability

IoT-EMS integration promotes energy efficiency and sustainability in manufacturing processes. By monitoring and optimizing energy consumption, EMS manufacturers can reduce their environmental impact and achieve cost savings.

Energy Monitoring and Optimization

IoT sensors can monitor energy consumption at various points in the manufacturing process, identifying energy-intensive operations and inefficiencies. By analyzing this data, EMS manufacturers can implement energy optimization strategies, such as optimizing machine settings, reducing idle time, and implementing energy-efficient equipment.

Sustainable Manufacturing Practices

IoT technologies enable EMS manufacturers to adopt sustainable manufacturing practices, such as waste reduction, resource conservation, and circular economy principles. By tracking and optimizing material usage, minimizing waste, and facilitating product lifecycle management, IoT-EMS integration contributes to a more sustainable and environmentally friendly manufacturing ecosystem.

6. Predictive Analytics and Decision Support

IoT-EMS integration enables predictive analytics and decision support, empowering EMS manufacturers to make data-driven decisions. By collecting and analyzing vast amounts of data from connected devices and systems, EMS companies can gain valuable insights and make informed decisions.

Data-driven Insights

IoT technologies generate a wealth of data from various sources, including machines, sensors, and production processes. By applying advanced analytics and machine learning algorithms to this data, EMS manufacturers can uncover hidden patterns, identify trends, and gain insights into performance, quality, and efficiency.

Predictive Modeling and Optimization

Predictive analytics and modeling techniques can be applied to IoT data to anticipate future outcomes and optimize processes. By predicting demand, forecasting equipment failures, and simulating production scenarios, EMS manufacturers can make proactive decisions, optimize resource allocation, and improve overall operational performance.

7. Remote Monitoring and Control

IoT-EMS integration enables remote monitoring and control of manufacturing processes, allowing EMS manufacturers to oversee operations from anywhere, at any time. This capability is particularly valuable for managing distributed manufacturing sites or collaborating with global partners.

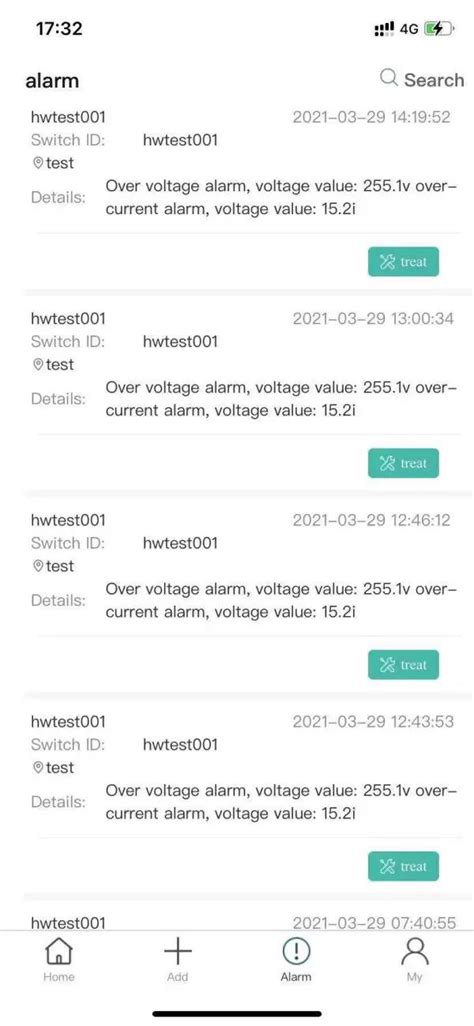

Real-time Visibility and Alerts

IoT devices and sensors provide real-time visibility into manufacturing processes, enabling remote monitoring of key performance indicators, machine status, and quality metrics. EMS manufacturers can receive alerts and notifications for critical events, such as equipment failures or quality deviations, allowing for prompt action and minimizing downtime.

Remote Troubleshooting and Maintenance

IoT-enabled remote troubleshooting and maintenance capabilities allow EMS manufacturers to diagnose and resolve issues remotely. By accessing machine data, logs, and performance metrics remotely, technical experts can provide support, perform remote diagnostics, and guide on-site personnel through maintenance procedures, reducing the need for physical interventions and minimizing response times.

8. Enhanced Collaboration and Communication

IoT-EMS integration fosters enhanced collaboration and communication among stakeholders, including employees, suppliers, and customers. By leveraging IoT technologies, EMS manufacturers can enable seamless information sharing and real-time updates, improving overall coordination and decision-making.

Connected Workforce

IoT-enabled wearable devices and mobile applications can keep employees connected and informed, providing real-time access to production data, work instructions, and safety alerts. This connected workforce can collaborate more effectively, share knowledge, and respond quickly to changing conditions or emergencies.

Supplier and Customer Integration

IoT technologies facilitate integration with suppliers and customers, enabling real-time information exchange and collaboration. By sharing production schedules, inventory levels, and quality data through IoT-enabled portals or APIs, EMS manufacturers can strengthen partnerships, improve responsiveness, and align supply chain activities with customer demands.

9. Compliance and Traceability

IoT-EMS integration supports compliance and traceability requirements, ensuring that EMS manufacturers adhere to regulatory standards and customer specifications. By leveraging IoT technologies, EMS companies can track and document every step of the manufacturing process, from raw materials to finished products.

Automated Data Collection and Documentation

IoT devices and sensors can automatically collect and record data related to production processes, quality inspections, and material usage. This automated data collection eliminates the need for manual documentation, reduces errors, and ensures accurate and reliable records for compliance purposes.

Product Traceability and Genealogy

IoT technologies enable end-to-end product traceability and genealogy, allowing EMS manufacturers to track the origin, history, and movement of materials, components, and finished products. This traceability is critical for quality control, recalls, and regulatory compliance, as it provides a comprehensive audit trail and facilitates root cause analysis.

10. Competitive Advantage and Innovation

IoT-EMS integration provides a competitive advantage and fosters innovation in the EMS industry. By embracing IoT technologies, EMS manufacturers can differentiate themselves, offer value-added services, and stay ahead of the curve in an increasingly competitive market.

Differentiation and Value-added Services

IoT-enabled capabilities, such as real-time monitoring, predictive maintenance, and customization, allow EMS manufacturers to differentiate themselves from competitors and offer value-added services to customers. By leveraging IoT technologies, EMS companies can provide enhanced visibility, responsiveness, and support, strengthening customer relationships and loyalty.

Innovation and Future-proofing

IoT-EMS integration opens up opportunities for innovation and future-proofing in the EMS industry. By staying at the forefront of IoT adoption, EMS manufacturers can explore new business models, develop smart and connected products, and leverage emerging technologies, such as artificial intelligence and blockchain, to drive continuous improvement and stay ahead of market trends.

Frequently Asked Questions (FAQ)

-

What is IoT-EMS integration?

IoT-EMS integration refers to the convergence of the Internet of Things (IoT) technologies with Electronic Manufacturing Services (EMS) processes. It involves the deployment of IoT devices, sensors, and connectivity solutions to monitor, control, and optimize manufacturing operations in the EMS industry. -

How does IoT-EMS integration improve efficiency and productivity?

IoT-EMS integration improves efficiency and productivity by enabling real-time monitoring and control of manufacturing processes. IoT devices and sensors collect data on machine performance, production metrics, and quality parameters, allowing EMS manufacturers to identify inefficiencies, optimize processes, and reduce downtime through predictive maintenance and data-driven decision-making. -

What role does IoT play in quality control in EMS manufacturing?

IoT technologies play a crucial role in enhancing quality control in EMS manufacturing. By deploying IoT sensors to monitor critical quality parameters, such as temperature, humidity, and vibration, EMS manufacturers can detect deviations from set standards in real-time. IoT-enabled automated inspection and testing systems can perform high-precision quality checks, reducing defects and ensuring consistent product quality. -

How does IoT-EMS integration enable customization and flexibility in manufacturing?

IoT-EMS integration enables customization and flexibility in manufacturing by facilitating flexible manufacturing systems and mass customization. IoT technologies allow EMS manufacturers to quickly reconfigure machines and processes based on real-time data and customer requirements, enabling efficient handling of small batches, personalized products, and frequent design changes. -

What are the benefits of IoT-EMS integration for compliance and traceability?

IoT-EMS integration supports compliance and traceability requirements by enabling automated data collection and documentation. IoT devices and sensors can automatically record data related to production processes, quality inspections, and material usage, ensuring accurate and reliable records for compliance purposes. IoT technologies also enable end-to-end product traceability and genealogy, facilitating quality control, recalls, and regulatory compliance.

Conclusion

IoT-EMS integration is transforming the Electronic Manufacturing Services industry, offering numerous benefits and driving innovation. By leveraging IoT technologies, EMS manufacturers can enhance efficiency, improve quality control, optimize inventory management, enable customization and flexibility, promote sustainability, and gain a competitive advantage. As the adoption of IoT in EMS manufacturing continues to grow, it is evident that IoT plays a crucial role in shaping the future of the industry. EMS companies that embrace IoT-EMS integration will be well-positioned to navigate the challenges of an increasingly connected and data-driven manufacturing landscape, delivering value to their customers and driving long-term success.

| Benefit | Description |

|---|---|

| Enhanced Efficiency and Productivity | IoT-EMS integration enables real-time monitoring and control of manufacturing processes, leading to improved efficiency and productivity through data-driven optimization and predictive maintenance. |

| Improved Quality Control | IoT technologies enhance quality control processes, allowing EMS manufacturers to monitor critical parameters in real-time, detect deviations, and perform automated inspection and testing. |

| Inventory Management and Supply Chain Optimization | IoT-EMS integration streamlines inventory management and optimizes supply chain operations through real-time inventory tracking and end-to-end supply chain transparency. |

| Customization and Flexibility | IoT technologies enable flexible manufacturing systems and mass customization, allowing EMS manufacturers to adapt to changing customer requirements and offer personalized products. |

| Energy Efficiency and Sustainability | IoT-EMS integration promotes energy efficiency and sustainability by monitoring and optimizing energy consumption and enabling sustainable manufacturing practices. |

[EMS]: Electronic Manufacturing Services

[IoT]: Internet of Things

No responses yet