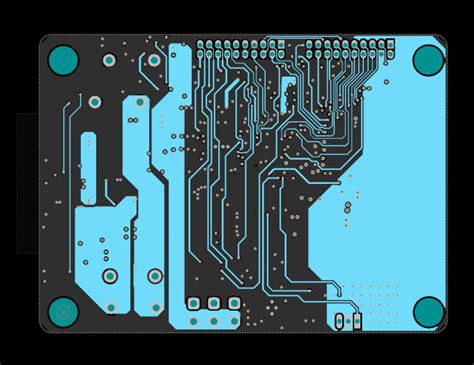

Introduction to 10 Ounce Copper PCBs

10 ounce copper PCBs are a type of printed circuit board that features a thicker copper layer compared to standard PCBs. The increased copper thickness offers several advantages, such as improved current carrying capacity, enhanced thermal management, and better mechanical stability. These benefits make 10 ounce copper PCBs a popular choice for high-power applications, including power electronics, automotive systems, and industrial equipment.

Advantages of 10 Ounce Copper PCBs

- Higher Current Carrying Capacity

- Thicker copper layers allow for increased current flow without overheating

-

Suitable for high-power applications and devices with high current demands

-

Improved Thermal Management

- Enhanced heat dissipation due to the increased copper thickness

-

Helps prevent thermal issues and increases the lifespan of components

-

Better Mechanical Stability

- Thicker copper provides a more robust and stable PCB structure

-

Reduces the risk of warping or bending during manufacturing and operation

-

Reduced Voltage Drop

- Higher copper thickness minimizes voltage drop across the PCB

-

Ensures consistent power delivery to components

-

Compatibility with High-Temperature Applications

- 10 ounce copper PCBs can withstand higher operating temperatures

- Ideal for applications in harsh environments or near heat-generating components

Applications of 10 Ounce Copper PCBs

10 ounce copper PCBs find applications in various industries and products that require high power handling and reliability. Some common applications include:

- Power Electronics

- Power inverters and converters

- Motor drives and controllers

-

Uninterruptible power supplies (UPS)

-

Automotive Systems

- Electric vehicle battery management systems

- Engine control units (ECUs)

-

Automotive lighting and power distribution

-

Industrial Equipment

- Heavy machinery and robotics

- High-current sensors and actuators

-

Power supplies and distribution systems

-

Telecommunications

- Base stations and towers

- Power amplifiers and RF circuits

-

Satellite communication systems

-

Renewable Energy

- Solar inverters and charge controllers

- Wind turbine power converters

- Energy storage systems

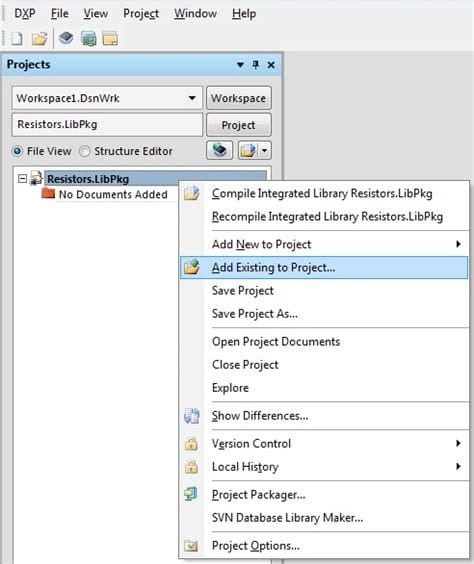

PCB Design Library Migration

PCB design library migration is the process of transferring design elements, components, and symbols from one PCB design software to another. This migration becomes necessary when switching to a new design tool, collaborating with teams using different software, or consolidating design resources. Efficient library migration ensures consistency, compatibility, and seamless integration of existing designs into the new environment.

Challenges in PCB Design Library Migration

- Incompatible File Formats

- Different PCB design software may use proprietary or incompatible file formats

-

Manual conversion or specialized tools may be required for successful migration

-

Component Symbol and Footprint Inconsistencies

- Component symbols and footprints may vary between design libraries

-

Ensuring accurate mapping and translation of symbols and footprints is crucial

-

Design Rule Differences

- Each PCB design software has its own set of design rules and constraints

-

Migrating design rules and constraints requires careful review and adaptation

-

Naming Conventions and Hierarchies

- Library organization, naming conventions, and hierarchies may differ between tools

-

Maintaining a consistent and logical structure during migration is essential

-

Version Compatibility

- Different versions of the same PCB design software may have varying features and capabilities

- Ensuring compatibility between the source and target software versions is important

Best Practices for PCB Design Library Migration

- Plan and Assess the Migration Scope

- Identify the libraries, components, and designs to be migrated

- Determine the target PCB design software and version

-

Assess the compatibility and challenges involved in the migration process

-

Create a Backup and Version Control

- Make a backup of the existing design libraries before starting the migration

-

Implement version control to track changes and revert if necessary

-

Use Automated Migration Tools

- Utilize dedicated library migration tools provided by PCB design software vendors

-

Automated tools can streamline the process and minimize manual effort

-

Review and Validate Migrated Libraries

- Thoroughly review the migrated libraries to ensure accuracy and completeness

-

Verify component symbols, footprints, and design rules against the original library

-

Establish Naming Conventions and Organization

- Define and adhere to consistent naming conventions for components and libraries

-

Organize the migrated libraries in a logical and hierarchical manner

-

Collaborate and Communicate with the Team

- Involve relevant team members in the migration process

-

Communicate the changes, guidelines, and best practices to ensure smooth adoption

-

Test and Verify Migrated Designs

- Conduct thorough testing of migrated designs to validate functionality and performance

- Compare the results with the original designs to ensure consistency

Tools for PCB Design Library Migration

Several tools are available to assist in PCB design library migration. Some popular options include:

- Altium Library Migrator

- Supports migration from various PCB design tools to Altium Designer

-

Provides automated conversion of components, footprints, and design rules

-

Eagle Library Converter

- Enables migration of libraries from Autodesk Eagle to other PCB design software

-

Supports conversion of Schematic symbols, footprints, and design rules

-

KiCad Library Converter

- Facilitates migration of libraries to and from KiCad PCB design software

-

Supports various file formats and provides customization options

-

Mentor Graphics Library Migrator

- Allows migration of libraries to Mentor Graphics PCB design tools

-

Offers automated conversion and mapping of components and design data

-

Zuken Library Migrator

- Assists in migrating libraries to Zuken CR-8000 and CR-5000 PCB design software

- Provides comprehensive migration capabilities for components, constraints, and design data

| Tool | Source Software | Target Software |

|---|---|---|

| Altium Library Migrator | Various PCB design tools | Altium Designer |

| Eagle Library Converter | Autodesk Eagle | Various PCB design tools |

| KiCad Library Converter | Various PCB design tools | KiCad |

| Mentor Graphics Library Migrator | Various PCB design tools | Mentor Graphics |

| Zuken Library Migrator | Various PCB design tools | Zuken CR-8000/CR-5000 |

Frequently Asked Questions (FAQ)

-

Q: What are the benefits of using 10 ounce copper PCBs?

A: 10 ounce copper PCBs offer several benefits, including higher current carrying capacity, improved thermal management, better mechanical stability, reduced voltage drop, and compatibility with high-temperature applications. These advantages make them suitable for high-power and demanding applications. -

Q: Are 10 ounce copper PCBs more expensive than standard PCBs?

A: Yes, 10 ounce copper PCBs are generally more expensive than standard PCBs due to the increased amount of copper used in their construction. The higher cost is justified by the enhanced performance and reliability they offer in high-power applications. -

Q: Can I migrate my PCB design libraries between different software tools?

A: Yes, PCB design library migration is possible between different software tools. However, the process can be challenging due to incompatible file formats, component inconsistencies, and design rule differences. Using automated migration tools and following best practices can streamline the migration process. -

Q: What should I consider before starting a PCB design library migration?

A: Before starting a PCB design library migration, consider factors such as the scope of migration, target software and version, compatibility challenges, and the need for consistent naming conventions and organization. Planning and assessment are crucial for a successful migration. -

Q: Are there any automated tools available for PCB design library migration?

A: Yes, there are several automated tools available for PCB design library migration, such as Altium Library Migrator, Eagle Library Converter, KiCad Library Converter, Mentor Graphics Library Migrator, and Zuken Library Migrator. These tools assist in converting and mapping components, footprints, and design rules between different PCB design software.

Conclusion

10 ounce copper PCBs offer significant advantages over standard PCBs, making them a preferred choice for high-power applications. Their increased copper thickness provides higher current carrying capacity, improved thermal management, better mechanical stability, and reduced voltage drop. These benefits are crucial in industries such as power electronics, automotive systems, industrial equipment, telecommunications, and renewable energy.

When migrating PCB design libraries between different software tools, it is essential to plan and assess the migration scope, create backups, use automated migration tools, review and validate the migrated libraries, establish consistent naming conventions, collaborate with the team, and thoroughly test the migrated designs. By following best practices and utilizing the right tools, PCB design library migration can be accomplished efficiently, ensuring compatibility and seamless integration of existing designs into the new environment.

As technology continues to evolve, the demand for high-performance PCBs and the need for efficient design library migration will only increase. By staying informed about advancements in PCB manufacturing techniques and design tools, engineers and designers can leverage the benefits of 10 ounce copper PCBs and streamline their design processes through effective library migration strategies.

No responses yet