Introduction

Printed Circuit Board (PCB) soldering is a crucial process in electronics manufacturing that involves joining electronic components to the PCB using molten solder. Proper PCB soldering ensures the reliability and longevity of electronic devices. However, several issues can arise during the soldering process that can compromise the quality and functionality of the PCB. In this article, we will discuss ten critical issues that we need to pay attention to in PCB soldering.

1. Solder Bridges

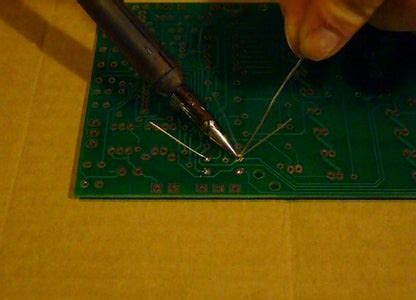

What are Solder Bridges?

Solder bridges occur when excess solder accidentally connects two or more component leads or PCB pads that should not be connected. This can cause short circuits and lead to device malfunction.

Causes of Solder Bridges

- Applying too much solder

- Incorrect soldering iron temperature

- Improper soldering technique

- Inadequate cleaning of the PCB before soldering

Prevention and Correction

- Use the appropriate amount of solder

- Maintain the correct soldering iron temperature

- Practice proper soldering technique

- Clean the PCB thoroughly before soldering

- Use a solder wick or desoldering pump to remove excess solder

2. Cold Solder Joints

What are Cold Solder Joints?

Cold solder joints occur when the solder does not melt completely, resulting in a weak and unreliable connection between the component and the PCB pad.

Causes of Cold Solder Joints

- Insufficient heat applied during soldering

- Dirty or oxidized component leads or PCB pads

- Incorrect soldering iron tip size or shape

- Inadequate flux application

Prevention and Correction

- Ensure the soldering iron is at the correct temperature

- Clean the component leads and PCB pads before soldering

- Use the appropriate soldering iron tip size and shape

- Apply enough flux to promote proper solder flow

- Reheat and reflow the solder joint if necessary

3. Tombstoning

What is Tombstoning?

Tombstoning, also known as “drawbridging,” occurs when a surface-mounted component (SMD) stands up on one end during the soldering process, resulting in one lead not being soldered to the PCB pad.

Causes of Tombstoning

- Uneven heating of the component leads

- Incorrect placement of the component on the PCB

- Inadequate solder paste application

- Rapid temperature changes during soldering

Prevention and Correction

- Ensure even heating of the component leads

- Properly place the component on the PCB pads

- Apply the appropriate amount of solder paste

- Use a controlled heating and cooling process

- Reposition and resolder the component if tombstoning occurs

4. Solder Balls

What are Solder Balls?

Solder balls are small, spherical pieces of solder that can form on the PCB surface during the soldering process. They can cause short circuits and affect the PCB’s functionality.

Causes of Solder Balls

- Excessive solder paste application

- High soldering iron temperature

- Incorrect soldering technique

- Contamination on the PCB surface

Prevention and Correction

- Apply the appropriate amount of solder paste

- Maintain the correct soldering iron temperature

- Use proper soldering technique

- Keep the PCB surface clean and free from contaminants

- Remove solder balls using tweezers or a solder wick

5. Insufficient Solder

What is Insufficient Solder?

Insufficient solder occurs when not enough solder is applied to create a proper connection between the component and the PCB pad, resulting in a weak or open connection.

Causes of Insufficient Solder

- Applying too little solder

- Low soldering iron temperature

- Dirty or oxidized component leads or PCB pads

- Inadequate flux application

Prevention and Correction

- Use the appropriate amount of solder

- Ensure the soldering iron is at the correct temperature

- Clean the component leads and PCB pads before soldering

- Apply enough flux to promote proper solder flow

- Add more solder to the joint if necessary

6. Lifted Pads

What are Lifted Pads?

Lifted pads occur when the copper pad on the PCB separates from the board during the soldering process, causing a break in the electrical connection.

Causes of Lifted Pads

- Excessive heat applied during soldering

- Improper handling of the PCB

- Poor PCB design or manufacturing

- Mechanical stress on the component or PCB

Prevention and Correction

- Use the correct soldering iron temperature and duration

- Handle the PCB with care to avoid mechanical stress

- Ensure proper PCB design and manufacturing quality

- Secure the component to the PCB before soldering

- Repair lifted pads using conductive epoxy or jumper wires

7. Soldering Iron Temperature

Importance of Soldering Iron Temperature

Maintaining the correct soldering iron temperature is crucial for achieving reliable and high-quality solder joints. Incorrect temperatures can lead to various soldering issues.

Recommended Soldering Iron Temperatures

| Solder Type | Temperature Range |

|---|---|

| Lead-based | 315°C – 370°C |

| Lead-free | 370°C – 425°C |

Tips for Maintaining Proper Soldering Iron Temperature

- Use a temperature-controlled soldering iron

- Select the appropriate temperature for the solder type

- Monitor the soldering iron temperature regularly

- Clean and maintain the soldering iron tip

8. Flux Selection and Application

What is Flux?

Flux is a chemical compound that helps to remove oxides and impurities from the surfaces being soldered, promoting better solder flow and adhesion.

Types of Flux

| Flux Type | Characteristics |

|---|---|

| Rosin | Mild activation, suitable for most applications |

| Water-soluble | Stronger activation, requires post-soldering cleaning |

| No-clean | Leaves minimal residue, no cleaning required |

Proper Flux Application

- Select the appropriate flux type for the application

- Apply flux to the component leads and PCB pads before soldering

- Use the correct amount of flux to avoid excessive residue

- Clean the PCB after soldering if using water-soluble flux

9. Soldering Technique

Importance of Proper Soldering Technique

Using the correct soldering technique ensures the creation of reliable and high-quality solder joints while minimizing the risk of soldering issues.

Key Aspects of Proper Soldering Technique

- Heat the component lead and PCB pad simultaneously

- Apply solder to the joint, not the soldering iron tip

- Use the appropriate amount of solder

- Keep the soldering iron tip clean and well-maintained

- Avoid excessive movement of the component during soldering

Tips for Improving Soldering Technique

- Practice on scrap PCBs or soldering practice kits

- Watch instructional videos or attend soldering workshops

- Use magnification and proper lighting for better visibility

- Maintain a steady hand and control the soldering iron with precision

10. PCB Cleaning

Importance of PCB Cleaning

Cleaning the PCB after soldering helps to remove flux residue, solder balls, and other contaminants that can affect the PCB’s performance and reliability.

PCB Cleaning Methods

| Cleaning Method | Description |

|---|---|

| Isopropyl Alcohol | Commonly used for removing rosin flux residue |

| Deionized Water | Used for cleaning water-soluble flux residue |

| Ultrasonic Cleaning | Effective for removing stubborn contaminants |

Tips for Effective PCB Cleaning

- Select the appropriate cleaning method based on the flux type

- Use lint-free wipes or brushes to avoid leaving fibers on the PCB

- Ensure the PCB is completely dry before further processing or use

- Follow the manufacturer’s guidelines for cleaning solutions and methods

FAQ

1. What is the most common soldering issue in PCB assembly?

The most common soldering issue in PCB assembly is cold solder joints, which occur when the solder does not melt completely, resulting in a weak and unreliable connection.

2. How can I prevent tombstoning when soldering surface-mounted components?

To prevent tombstoning, ensure even heating of the component leads, properly place the component on the PCB pads, apply the appropriate amount of solder paste, and use a controlled heating and cooling process.

3. What should I do if I encounter lifted pads during the soldering process?

If you encounter lifted pads during soldering, you can repair them using conductive epoxy or jumper wires. To prevent lifted pads, use the correct soldering iron temperature and duration, handle the PCB with care, and ensure proper PCB design and manufacturing quality.

4. How do I select the appropriate flux for my soldering application?

When selecting flux, consider the type of soldering application and the required level of activation. Rosin flux is suitable for most applications, while water-soluble flux offers stronger activation but requires post-soldering cleaning. No-clean flux leaves minimal residue and does not require cleaning.

5. What are some tips for improving my soldering technique?

To improve your soldering technique, practice on scrap PCBs or soldering practice kits, watch instructional videos or attend soldering workshops, use magnification and proper lighting for better visibility, and maintain a steady hand and control the soldering iron with precision. Additionally, ensure that you heat the component lead and PCB pad simultaneously, apply solder to the joint (not the soldering iron tip), use the appropriate amount of solder, and keep the soldering iron tip clean and well-maintained.

Conclusion

Paying attention to these ten critical issues in PCB soldering can help ensure the reliability, functionality, and longevity of electronic devices. By understanding the causes and prevention methods for common soldering problems, selecting the appropriate tools and materials, and following best practices for soldering technique and PCB cleaning, you can achieve high-quality solder joints and minimize the risk of device failure. As electronics continue to advance and become more complex, mastering the art of PCB soldering remains an essential skill for professionals in the electronics manufacturing industry.

No responses yet