1. Look for Experience and Expertise

When searching for a PCB assembly service provider, it is essential to consider their experience and expertise in the industry. Look for companies that have been in business for several years and have a proven track record of delivering high-quality PCB assembly services. Experienced service providers are more likely to have the knowledge and skills necessary to handle complex projects and provide valuable insights to optimize your PCB design.

| Years in Business | Level of Expertise |

|---|---|

| 1-5 years | Beginner |

| 5-10 years | Intermediate |

| 10+ years | Expert |

How to Assess a Company’s Experience and Expertise

- Check their website and portfolio for information on their history and past projects

- Read customer reviews and testimonials

- Ask for references and contact them to inquire about their experience with the service provider

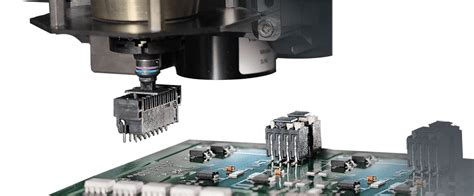

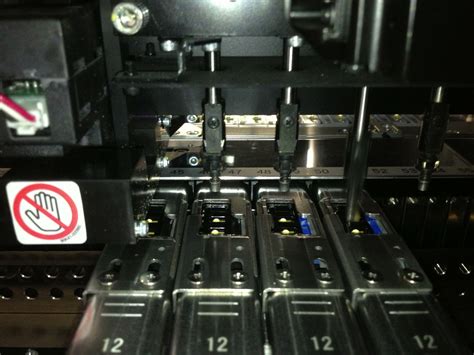

2. Consider Their Technical Capabilities

Different PCB assembly projects may require various technical capabilities. When choosing a PCB assembly service provider, ensure that they have the necessary equipment, technology, and skills to handle your specific project requirements. Some key technical capabilities to consider include:

- Surface Mount Technology (SMT) assembly

- Through-Hole Technology (THT) assembly

- Mixed technology assembly

- BGA and QFN packaging capabilities

- Automated Optical Inspection (AOI) and X-ray inspection

Types of PCB Assembly Technologies

| Technology | Description |

|---|---|

| SMT | Components are mounted directly onto the PCB surface |

| THT | Components are inserted through holes in the PCB |

| Mixed | A combination of SMT and THT technologies |

3. Evaluate Their Quality Control Processes

The quality of your PCB assembly can significantly impact the performance and reliability of your final product. When selecting a PCB assembly service provider, investigate their quality control processes to ensure they meet your standards. Some essential quality control processes include:

- Automated Optical Inspection (AOI)

- X-ray inspection

- In-circuit testing (ICT)

- Functional testing

- Visual inspection

Common Quality Control Standards

| Standard | Description |

|---|---|

| IPC-A-610 | Acceptability of Electronic Assemblies |

| IPC-J-STD-001 | Requirements for Soldered Electrical and Electronic Assemblies |

| ISO 9001 | Quality Management Systems |

4. Assess Their Communication and Customer Service

Effective communication and customer service are crucial when working with a PCB assembly service provider. Look for companies that are responsive, transparent, and willing to address your concerns and questions promptly. Good communication can help prevent misunderstandings, delays, and potential issues during the assembly process.

Communication Channels to Consider

- Phone

- Video conferencing

- Project management platforms

Signs of Good Customer Service

- Quick response times

- Clear and concise communication

- Willingness to provide updates and status reports

- Proactive problem-solving approach

5. Review Their Certifications and Standards Compliance

When choosing a PCB assembly service provider, it is essential to ensure that they comply with relevant industry certifications and standards. These certifications demonstrate the company’s commitment to quality, safety, and environmental responsibility. Some key certifications and standards to look for include:

- ISO 9001 (Quality Management Systems)

- IPC-A-610 (Acceptability of Electronic Assemblies)

- IPC-J-STD-001 (Requirements for Soldered Electrical and Electronic Assemblies)

- RoHS (Restriction of Hazardous Substances)

- UL (Underwriters Laboratories)

Benefits of Working with Certified PCB Assembly Service Providers

- Ensures consistent quality and reliability

- Demonstrates commitment to industry best practices

- Helps maintain compliance with regulatory requirements

- Reduces the risk of product failures and recalls

6. Consider Their Turnaround Time and Flexibility

When selecting a PCB assembly service provider, consider their turnaround time and flexibility to meet your project deadlines. Some projects may require faster turnaround times or the ability to accommodate last-minute changes. Look for service providers that offer a range of turnaround options and are willing to work with you to meet your specific needs.

Factors Affecting Turnaround Time

- Project complexity

- Component availability

- Manufacturing capacity

- Quality control processes

Ways to Ensure Faster Turnaround Times

- Provide clear and complete project specifications

- Order components in advance

- Maintain open communication with your service provider

- Consider expedited shipping options

7. Evaluate Their Pricing and Cost Structure

Cost is an important factor when choosing a PCB assembly service provider, but it should not be the only consideration. When evaluating pricing, consider the overall value provided by the service provider, including quality, reliability, and customer service. Some key factors to consider when assessing pricing and cost structure include:

- Setup fees

- Component sourcing costs

- Manufacturing costs

- Shipping and handling fees

- Minimum order quantities (MOQs)

Strategies for Managing PCB Assembly Costs

- Optimize your PCB design for manufacturability

- Consolidate orders to take advantage of volume discounts

- Consider offshore manufacturing options for larger production runs

- Negotiate pricing based on long-term partnerships and repeat business

8. Inquire About Their Supply Chain Management

Effective supply chain management is crucial for ensuring the timely and cost-effective delivery of your PCB assembly project. When selecting a PCB assembly service provider, inquire about their supply chain management practices, including component sourcing, inventory management, and vendor relationships.

Key Aspects of Supply Chain Management

- Component sourcing strategies

- Vendor qualification and management

- Inventory management and control

- Risk management and contingency planning

Benefits of Effective Supply Chain Management

- Ensures component availability and reduces lead times

- Minimizes the risk of supply chain disruptions

- Helps control costs through strategic sourcing and vendor partnerships

- Enables faster time-to-market for your products

9. Consider Their Design for Manufacturing (DFM) Support

Design for Manufacturing (DFM) is an essential process that helps optimize your PCB design for manufacturability, reliability, and cost-effectiveness. When choosing a PCB assembly service provider, consider their DFM support and expertise. A service provider with strong DFM capabilities can help you identify and address potential design issues early in the process, reducing the risk of costly revisions and delays.

Benefits of DFM Support

- Identifies and resolves design issues before production

- Optimizes PCB design for manufacturability and reliability

- Reduces the risk of production delays and quality issues

- Helps control manufacturing costs

DFM Checklist

- Board size and thickness

- Component placement and spacing

- Trace width and spacing

- Via size and placement

- Solder mask and silkscreen specifications

10. Look for Value-Added Services

When selecting a PCB assembly service provider, consider the value-added services they offer beyond basic assembly. These services can help streamline your product development process, reduce costs, and improve overall product quality. Some common value-added services include:

- PCB design and layout

- Component sourcing and procurement

- Testing and validation

- Box build and system integration

- Logistics and shipping

Benefits of Value-Added Services

- Simplifies the product development process

- Reduces the need for multiple vendors and service providers

- Helps ensure compatibility and interoperability of components and subsystems

- Provides a single point of contact for project management and support

FAQ

1. What is the difference between SMT and THT PCB assembly?

SMT (Surface Mount Technology) and THT (Through-Hole Technology) are two different methods of assembling components onto a PCB. SMT involves placing components directly onto the surface of the board, while THT requires inserting component leads through holes drilled in the board. SMT is generally faster and more space-efficient, while THT is often used for larger, heavier components or in applications requiring greater mechanical strength.

2. How do I choose between onshore and offshore PCB assembly services?

The decision between onshore and offshore PCB assembly services depends on various factors, including cost, turnaround time, quality requirements, and intellectual property concerns. Onshore services typically offer faster turnaround times, easier communication, and better IP protection, but may be more expensive. Offshore services can provide cost savings and are well-suited for larger production runs, but may have longer lead times and require more careful management of quality and communication.

3. What is the typical turnaround time for a PCB assembly project?

The typical turnaround time for a PCB assembly project varies depending on factors such as project complexity, component availability, and manufacturing capacity. Simple projects with readily available components may have turnaround times as short as a few days, while more complex projects or those requiring specialized components may take several weeks. It is essential to discuss turnaround time requirements with your service provider early in the project and plan accordingly.

4. How can I ensure the quality of my PCB assembly project?

To ensure the quality of your PCB assembly project, work with a reputable service provider that has a proven track record of quality and reliability. Look for providers with robust quality control processes, such as automated optical inspection (AOI), X-ray inspection, and functional testing. Ensure that your provider complies with relevant industry standards and certifications, such as IPC-A-610 and ISO 9001. Additionally, provide clear and detailed project specifications, maintain open communication, and consider implementing a quality assurance plan with your service provider.

5. What should I consider when comparing pricing between PCB assembly service providers?

When comparing pricing between PCB assembly service providers, consider the overall value provided, not just the initial cost. Factors to consider include the quality of materials and workmanship, turnaround time, customer service, and value-added services. Be aware of hidden costs, such as setup fees, component sourcing costs, and minimum order quantities (MOQs). Consider the long-term cost implications of working with a particular provider, including the potential for cost savings through volume discounts, design optimizations, and supply chain management.

In conclusion, choosing the right PCB assembly service provider is essential for the success of your electronic product development. By considering these 10 key tips, including experience, technical capabilities, quality control, communication, certifications, turnaround time, pricing, supply chain management, DFM support, and value-added services, you can make an informed decision and select a provider that best meets your needs. Remember to prioritize quality, reliability, and long-term value over short-term cost savings, and maintain open communication with your chosen provider throughout the project to ensure a successful outcome.

No responses yet