Introduction to PCB Assembly

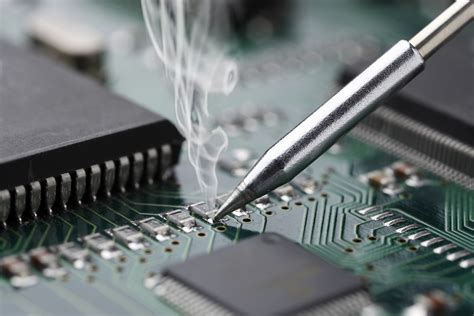

Printed Circuit Board (PCB) assembly is a crucial process in the manufacturing of electronic devices. It involves the placement and soldering of electronic components onto a printed circuit board, which forms the backbone of the device. Choosing the right PCB assembly services is essential to ensure the quality, reliability, and functionality of your electronic products.

In this article, we will discuss 10 good tips on selecting the best PCB assembly services for your needs. We will cover various aspects such as experience, technology, quality control, cost, and more, to help you make an informed decision.

Tip 1: Look for Experience and Expertise

When choosing a PCB assembly service provider, it is crucial to consider their experience and expertise in the industry. Look for companies that have been in the business for a considerable amount of time and have a proven track record of delivering high-quality PCB assembly services.

Benefits of Choosing an Experienced PCB Assembly Service Provider

- Streamlined processes and efficient workflows

- Ability to handle complex PCB designs and challenging projects

- Familiarity with industry standards and regulations

- Access to a wide range of resources and expertise

Tip 2: Evaluate the Technology and Equipment

The technology and equipment used by a PCB assembly service provider play a significant role in determining the quality and efficiency of their services. Ensure that the company you choose has state-of-the-art equipment and employs the latest technologies in PCB assembly.

Key Technologies and Equipment to Look for

- Surface Mount Technology (SMT) lines

- Automated Optical Inspection (AOI) systems

- X-ray inspection machines

- Reflow soldering ovens

- Wave soldering machines

Tip 3: Assess Quality Control Measures

Quality control is a critical aspect of PCB assembly, as it ensures that the final product meets the required standards and specifications. When selecting a PCB assembly service provider, inquire about their quality control measures and certifications.

Important Quality Control Measures and Certifications

- ISO 9001 certification

- IPC standards compliance (e.g., IPC-A-610, IPC-J-STD-001)

- In-process inspection and testing

- Traceability and documentation

- Electrostatic Discharge (ESD) protection

Tip 4: Consider the Range of Services Offered

A comprehensive PCB assembly service provider should offer a wide range of services to cater to your specific needs. This may include PCB design, prototyping, component sourcing, assembly, testing, and even box build services.

Advantages of Choosing a Full-Service PCB Assembly Provider

- Streamlined communication and project management

- Reduced lead times and faster time-to-market

- Cost savings through bundled services

- Consistency and quality across all stages of the project

Tip 5: Evaluate their Supply Chain Management

Effective supply chain management is crucial for timely and cost-effective PCB assembly. Ensure that the service provider you choose has a robust supply chain network and can source components reliably and efficiently.

Key Aspects of Supply Chain Management

- Established relationships with component suppliers

- Inventory management and stock optimization

- Ability to handle obsolete or hard-to-find components

- Flexibility to accommodate changes in demand or specifications

Tip 6: Analyze their Communication and Support

Clear communication and responsive support are essential for a successful PCB assembly project. Look for a service provider that offers transparent communication channels, regular updates, and prompt support throughout the project.

Importance of Effective Communication and Support

- Timely resolution of issues and concerns

- Collaborative approach to project management

- Regular progress reports and status updates

- Accessibility and responsiveness of the support team

Tip 7: Review their Pricing and Cost Structure

Cost is an important consideration when choosing a PCB assembly service provider. However, it is crucial to strike a balance between cost and quality. Look for a company that offers competitive pricing without compromising on the quality of their services.

Factors to Consider When Evaluating Pricing

- Transparency in pricing and quotations

- Cost breakdowns for different services and components

- Volume discounts and long-term partnerships

- Hidden costs or additional fees

Tip 8: Examine their Turnaround Time and Flexibility

Turnaround time is a critical factor in PCB assembly projects, especially for time-sensitive applications. Ensure that the service provider you choose can meet your deadlines and has the flexibility to accommodate urgent requests or changes in specifications.

Benefits of Fast Turnaround Time and Flexibility

- Faster time-to-market for your products

- Ability to respond to changing market demands

- Reduced risk of project delays and associated costs

- Competitive advantage in the industry

Tip 9: Evaluate their Environmental and Social Responsibility

In today’s world, environmental and social responsibility are becoming increasingly important. Choose a PCB assembly service provider that adheres to eco-friendly practices and demonstrates a commitment to corporate social responsibility.

Key Aspects of Environmental and Social Responsibility

- Compliance with environmental regulations and standards

- Use of lead-free and RoHS-compliant components

- Waste management and recycling practices

- Fair labor practices and employee welfare

- Community engagement and social initiatives

Tip 10: Request References and Case Studies

Before finalizing your decision, request references and case studies from the PCB assembly service providers you are considering. This will give you valuable insights into their past projects, client satisfaction, and overall performance.

Benefits of Reviewing References and Case Studies

- Validation of the service provider’s claims and capabilities

- Opportunity to learn from the experiences of other clients

- Assess the service provider’s ability to handle projects similar to yours

- Gain confidence in your decision-making process

FAQs

1. What is the difference between through-hole and surface mount PCB assembly?

Through-hole PCB assembly involves inserting component leads through holes drilled in the PCB and soldering them on the opposite side. Surface mount PCB assembly, on the other hand, involves placing components directly onto the surface of the PCB and soldering them using reflow or wave soldering techniques. Surface mount technology allows for smaller components and higher density PCB designs.

2. How long does a typical PCB assembly project take?

The duration of a PCB assembly project depends on various factors such as the complexity of the design, the availability of components, and the production volume. Simple PCB assemblies can take a few days, while more complex projects may require several weeks. It is essential to discuss your specific requirements and timelines with the service provider to ensure that they can meet your needs.

3. What certifications should I look for in a PCB assembly service provider?

Some of the key certifications to look for in a PCB assembly service provider include:

- ISO 9001: Quality Management System certification

- IPC-A-610: Acceptability of Electronic Assemblies standard

- IPC-J-STD-001: Requirements for Soldered Electrical and Electronic Assemblies standard

- UL (Underwriters Laboratories) certification for safety and compliance

These certifications demonstrate the service provider’s commitment to quality, reliability, and adherence to industry standards.

4. Can I provide my own components for PCB assembly?

Yes, many PCB assembly service providers offer consignment services, where you can provide your own components for assembly. This can be beneficial if you have specific component requirements or have already sourced the components yourself. However, ensure that you discuss the details of the consignment process with the service provider, including the component specifications, packaging, and lead times.

5. What should I do if I encounter issues with the assembled PCBs?

If you encounter issues with the assembled PCBs, the first step is to contact your PCB assembly service provider and report the problem. Most reputable service providers have a dedicated support team and a process for handling customer complaints and issues. They should work with you to identify the root cause of the problem and provide a suitable solution, such as rework, replacement, or refund, depending on the nature and severity of the issue.

Conclusion

Choosing the right PCB assembly services is crucial for the success of your electronic products. By considering factors such as experience, technology, quality control, range of services, supply chain management, communication, pricing, turnaround time, environmental responsibility, and references, you can make an informed decision and select a service provider that best suits your needs.

Remember, investing time and effort in finding the right PCB assembly partner can pay off in the long run, ensuring the quality, reliability, and competitiveness of your products in the market.

| Factor | Importance |

|---|---|

| Experience and Expertise | Ensures streamlined processes, efficient workflows, and ability to handle complex projects |

| Technology and Equipment | Determines the quality and efficiency of PCB assembly services |

| Quality Control Measures | Ensures that the final product meets the required standards and specifications |

| Range of Services | Offers streamlined communication, reduced lead times, and cost savings through bundled services |

| Supply Chain Management | Ensures timely and cost-effective PCB assembly through reliable component sourcing |

| Communication and Support | Enables timely resolution of issues, collaborative project management, and responsive support |

| Pricing and Cost Structure | Requires a balance between cost and quality, with transparency in pricing and cost breakdowns |

| Turnaround Time and Flexibility | Allows faster time-to-market, responsiveness to changing demands, and reduced risk of project delays |

| Environmental and Social Responsibility | Demonstrates commitment to eco-friendly practices, fair labor, and community engagement |

| References and Case Studies | Provides validation of the service provider’s claims, capabilities, and past performance |

By carefully evaluating these factors and following the tips outlined in this article, you can select the best PCB assembly services for your electronic products and ensure their success in the market.

No responses yet